Content .. 1129 1130 1131 1132 ..

Mitsubishi Outlander XL. Manual - part 1131

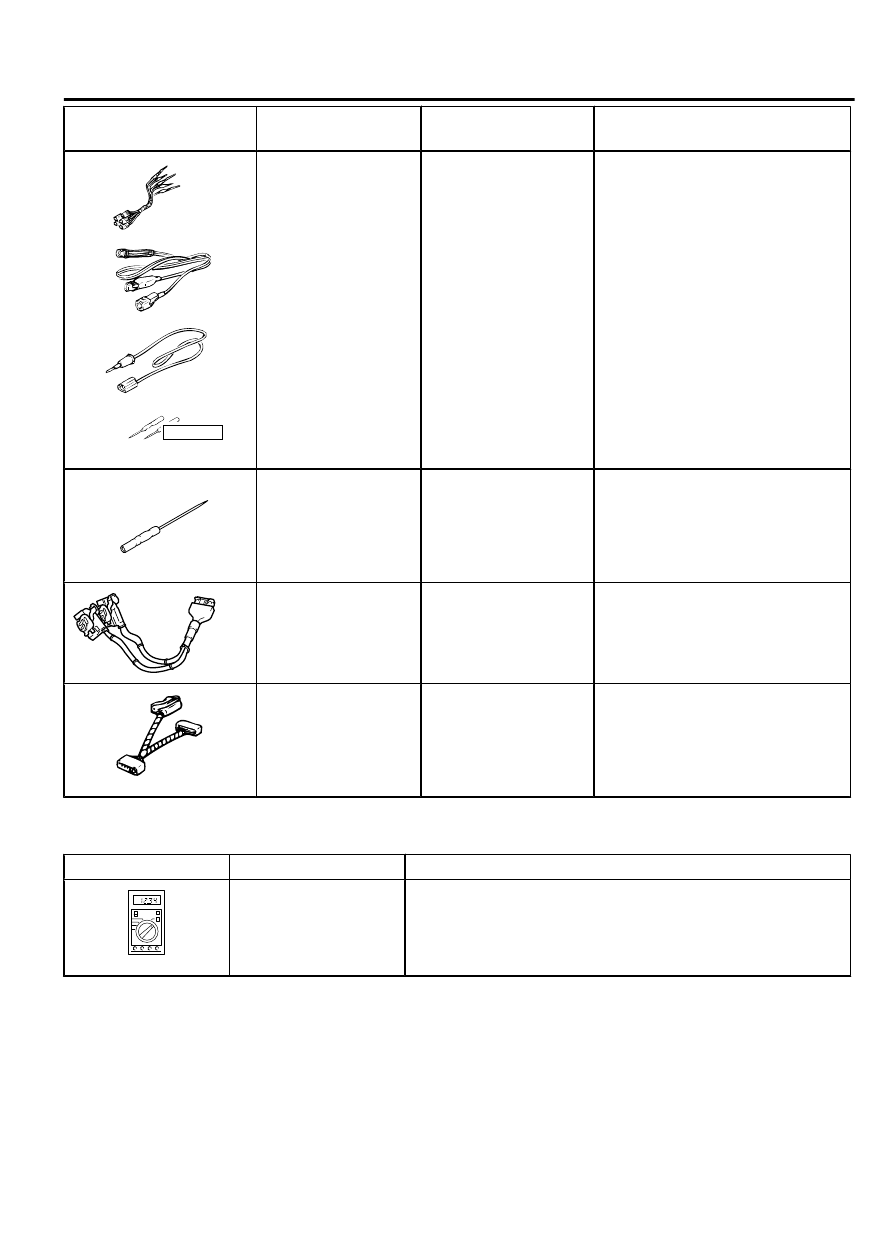

Tool

Tool number and

name

Supersession

Application

YB9912230000

Do not use

a

b

c

d

MB991223

a.

MB991219

b.

MB991220

c.

MB991221

d.

MB991222

Harness set

a.

Test harness

b.

LED harness

c.

LED

harness

adaptor

d.

Probe

General service tools Continuity check and voltage

measurement at harness wire or

connector for loose, corroded or

damaged terminals, or terminals

pushed back in the connector.

a.

Connector

pin

contact

pressure inspection

b.

Power circuit inspection

c.

Power circuit inspection

d.

Commercial tester connection

MB992006

MB992006

Extra fine probe

-

Continuity check and voltage

measurement at harness wire or

connector for loose, corroded or

damaged terminals, or terminals

pushed back in the connector.

MB991970

MB991970

ABS check harness

-

Measure

the

voltage

and

resistance at the ABS-ECU

MB991952

MB991952

ABS check harness

-

Measure

the

voltage

and

resistance at the ASC-ECU

TEST EQUIPMENT

M15408300043USA0000010000

Test equipment

Name

Use

ZC3000010000

Digital multimeter

Checking CAN bus circuit (for resistance and voltage

measurements)

CONTROLLER AREA NETWORK (CAN)

54D-7

TEST EQUIPMENT