Mitsubishi Outlander XL. Manual - part 73

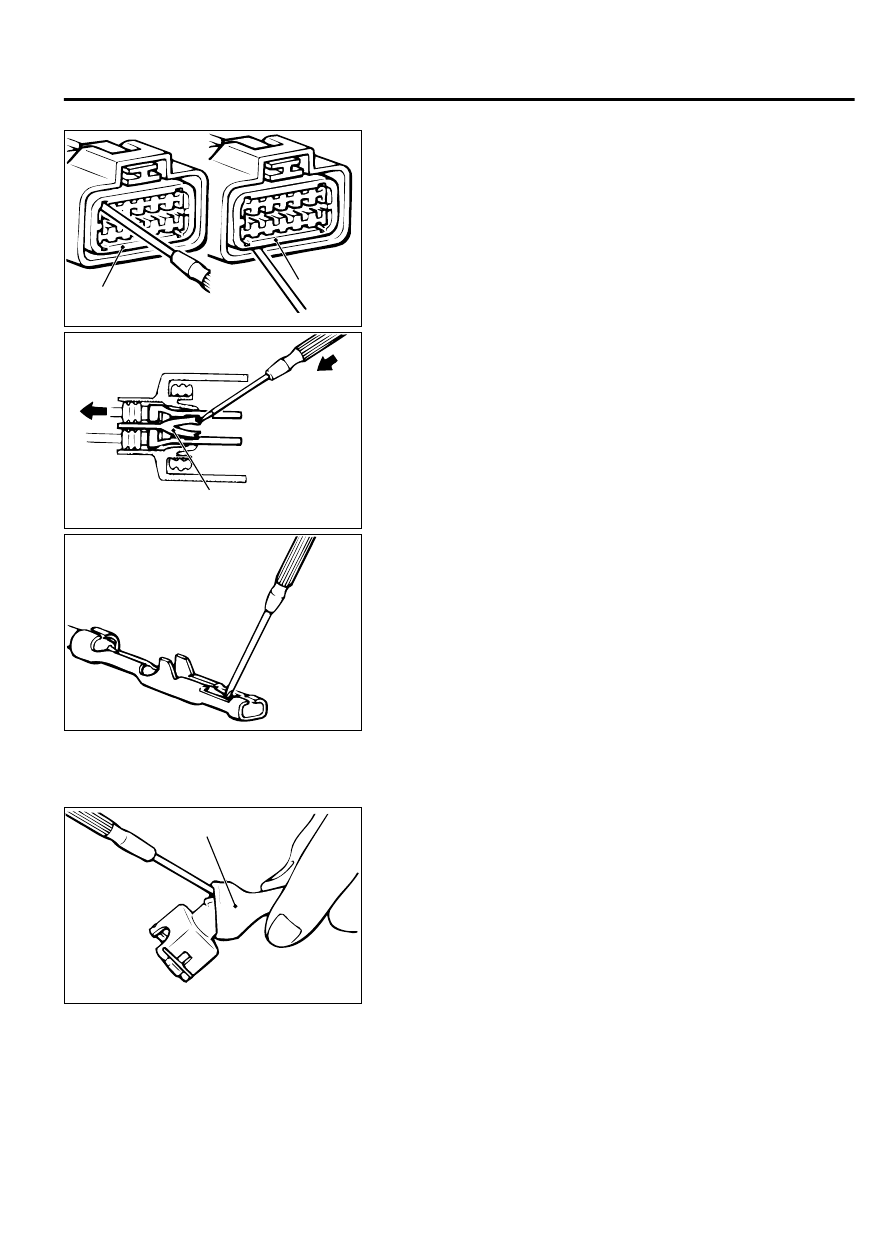

RECTANGULAR WATERPROOF CONNECTOR

ZC6001700000

Front

holder

Front holder

1.

Disengage the front holder with a screwdriver and remove it.

ZC6001710000

Housing lance

2.

Insert the tip of a screwdriver [0.8 mm (0.03 inch) width] into

the connector as shown in the figure, push it lightly to raise the

housing lance, and pull out the terminal.

ZC600172AA00

3.

Press the contact point to the male terminal down by holding

a screwdriver [1.4 mm (0.06 inch) width] as shown in the

figure. Lightly squeeze the outer edge so the flats are parallel

with the bottom.

INJECTOR CONNECTOR

ZC600173

Waterproof cap

0000

1.

Remove the waterproof cap.

GENERAL <ELECTRICAL>

00E-5

HARNESS CONNECTOR INSPECTION