Mitsubishi Outlander XL. Manual - part 60

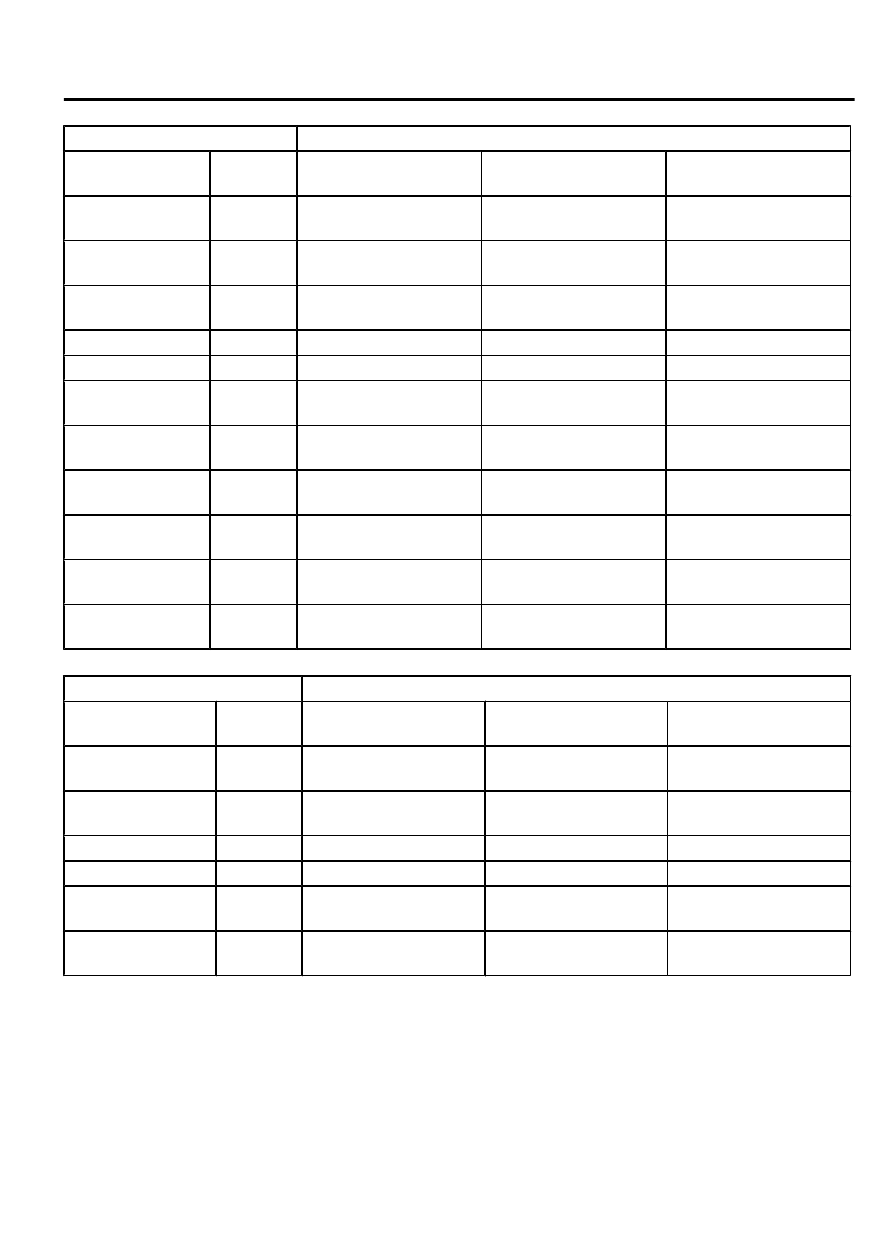

STANDARD BOLT AND NUT TIGHTENING TORQUE

Thread size

Standard tightening torque

Nominal

bolt

diameter (mm)

Pitch

(mm)

Head mark "4"

Head mark "7"

Head mark "8"

M5

0.8

2.5 ± 0.5 N·m (23 ± 4 in-

lb)

5.0 ± 1.0 N·m (44 ± 9 in-

lb)

6.0 ± 1.0 N·m (53 ± 9 in-

lb)

M6

1.0

5.0 ± 1.0 N·m (44 ± 9 in-

lb)

8.5 ± 1.5 N·m (76 ± 13

in-lb)

10 ± 2 N·m (89 ± 17 in-

lb)

M8

1.25

11 ± 2 N·m (98 ± 17 in-

lb)

20 ± 4 N·m (15 ± 3 ft-lb) 24 ± 4 N·m (18 ± 3 ft-lb)

M10

1.25

23 ± 4 N·m (17 ± 3 ft-lb) 42 ± 8 N·m (31 ± 6 ft-lb) 53 ± 7 N·m (39 ± 5 ft-lb)

M12

1.25

42 ± 8 N·m (31 ± 6 ft-lb) 80 ± 10 N·m (59 ± 7 ft-lb) 93 ± 12 N·m (68 ± 9 ft-lb)

M14

1.5

70 ± 10 N·m (52 ± 7 ft-lb) 130 ± 20 N·m (96 ± 15 ft-

lb)

150 ± 20 N·m (111 ± 14

ft-lb)

M16

1.5

105 ± 15 N·m (78 ± 11 ft-

lb)

195 ± 25 N·m (144 ± 18

ft-lb)

230 ± 30 N·m (170 ± 22

ft-lb)

M18

1.5

150 ± 20 N·m (111 ± 14

ft-lb)

290 ± 40 N·m (214 ± 29

ft-lb)

335 ± 45 N·m (247 ± 33

ft-lb)

M20

1.5

210 ± 30 N·m (155 ± 22

ft-lb)

400 ± 60 N·m (295 ± 44

ft-lb)

465 ± 65 N·m (343 ± 48

ft-lb)

M22

1.5

290 ± 40 N·m (214 ± 29

ft-lb)

540 ± 80 N·m (398 ± 59

ft-lb)

630 ± 90 N·m (465 ± 66

ft-lb)

M24

1.5

375 ± 55 N·m (277 ± 40

ft-lb)

705 ± 105 N·m (520 ± 77

ft-lb)

820 ± 120 N·m (605 ± 88

ft-lb)

FLANGE BOLT AND NUT TIGHTENING TORQUE

Thread size

Standard tightening torque

Nominal

bolt

diameter (mm)

Pitch

(mm)

Head mark "4"

Head mark "7"

Head mark "8"

M6

1.0

5.0 ± 1.0 N·m (44 ± 9 in-

lb)

10 ± 2 N·m (89 ± 17 in-

lb)

12 ± 2 N·m (107 ± 17 in-

lb)

M8

1.25

13 ± 2 N·m (111 ± 22 in-

lb)

24 ± 4 N·m (18 ± 3 ft-lb) 28 ± 5 N·m (20 ± 4 ft-lb)

M10

1.25

26 ± 5 N·m (19 ± 4 ft-lb) 50 ± 5 N·m (37 ± 4 ft-lb) 58 ± 7 N·m (43 ± 5 ft-lb)

M10

1.5

25 ± 4 N·m (18 ± 3 ft-lb) 46 ± 8 N·m (34 ± 6 ft-lb) 55 ± 5 N·m (41 ± 3 ft-lb)

M12

1.25

47 ± 9 N·m (35 ± 6 ft-lb) 93 ± 12 N·m (68 ± 9 ft-

lb)

105 ± 15 N·m (78 ± 11

ft-lb)

M12

1.75

43 ± 8 N·m (32 ± 6 ft-lb) 83 ± 12 N·m (61 ± 9 ft-

lb)

98 ± 12 N·m (72 ± 9 ft-

lb)

LUBRICATION AND MAINTENANCE

M10001000012USA0000010000

Maintenance

and

lubrication

service

recommendations have been compiled to provide

maximum protection for the vehicle owner's

investment against all reasonable types of driving

GENERAL <BODY AND CHASSIS>

00-49

LUBRICATION AND MAINTENANCE