Mitsubishi Outlander XL. Manual - part 49

Classifications of major maintenance / service points

When there are major points relative to maintenance and servicing procedures (such as essential maintenance

and service points, maintenance and service standard values, information regarding the use of special tools, etc.).

These are arranged together as major maintenance and service points and explained in detail.

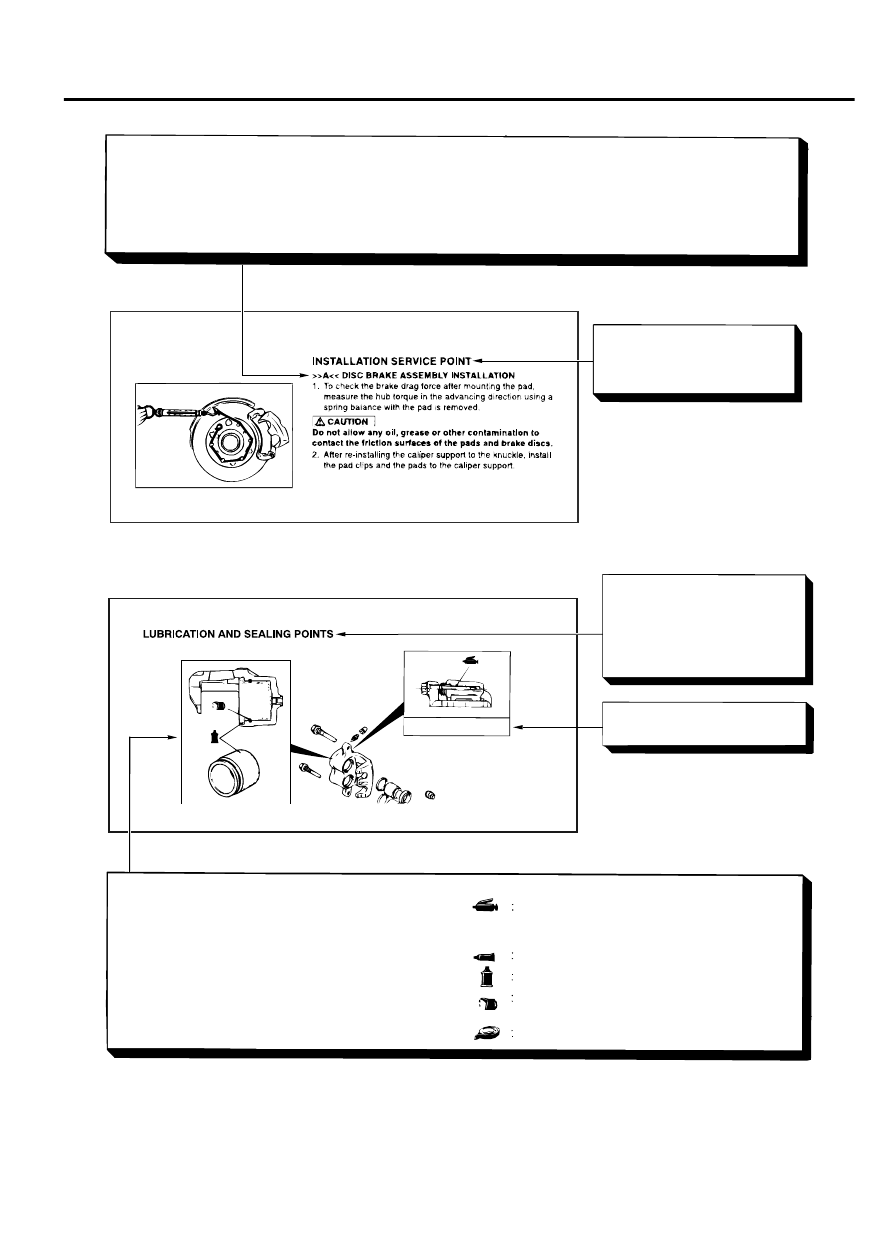

<<A>> : Indicates that there are essential points for removal or disassembly.

>>A<< : Indicates that there are essential points for installation or assembly.

Operating procedures,

cautions, etc. on removal,

installation, disassembly and

assembly are described

The title of the page

(following the page on which

the diagram of component

parts is presented) indicating

the locations of lubrication and

sealing procedures.

Indicates (by symbols) where

lubrication is necessary.

Symbols for lubrication, sealants and adhesives

Symbols are used to show the locations for lubrication

and for application of sealants and adhesives.

These symbols are included in the diagram of

component parts or on the page following the

component parts page. The symbols do not always

have accompanying text to support that symbol.

Adhesive tape or butyl rubber tape

Grease

(Multi-purpose grease unless there is a

brand or type specified)

Sealant or adhesive

Brake fluid or automatic transmission fluid

Engine oil, gear oil or air conditioning

compressor oil

Grease: repair kit grease

ZC6012880000

GENERAL <BODY AND CHASSIS>

00-5

HOW TO USE THIS MANUAL