Mitsubishi Outlander XL. Manual - part 42

Alternately repeat hammering and filing until there are file

traces over the entire repair area.

6.

Make a solder build-up at the repair.

7.

Finally, finish up the solder build-up using a body file.

USING A FRAME STRAIGHTENER

M40900000130USA0000010000

For serious and extensive damage, when for example

the damage extends to the frame of members, it is

necessary to first use a frame straightener to make a

rough, overall repair of the body, and then to proceed

to careful repairs of each individual area of damage.

When a frame straightener is used for body repairs, it

is a fundamental principle that the pulling should be in

the direction from which the impact was sustained,

and from the opposite direction. If this is, in error, not

done, previously undamaged components will be

deformed, and repair may become impossible.

It is for that reason that it is important to decide upon

the method of repair, especially regarding the initial

overall repair, by following the steps below.

OVERALL ROUGH REPAIRS

1.

First, analyze the impact. This means analysis and

consideration of the point of collision, the speed at

the time of collision, and the strength, weight and

shape of the object hit.

2.

Then get a complete understanding of the condition

of the existing damage. In particular, if the damage

extends to the suspension installation components,

an inspection must be made to determine whether

or not there is any deviation of the frame or body

alignment.

3.

Finally, determine what repair methods should be

used.

⦆

To what extent will frame straightening and other

overall repairs be necessary in order to restore the

damaged areas to the way they were?

⦆

At what stage of the repairs should panels adjoining

the components to be frame straightened, etc., be

removed?

⦆

Decide upon the work steps and restoration

methods to be followed after the rough, overall

repairs are completed.

Select the frame straightener based upon the results

of above, and use it to pull in the appropriate direction.

More than one direction may be appropriate,

depending upon the damage.

If the damage is of a moderate degree or less, it may

be possible to do all that is necessary in one pull.

If, however, the damage is major, that is to say if

repairs must be made to components of the

passenger compartment such as the dash panel, etc.,

it may be necessary, after completing the first pull, to

set up the frame straightener at a different position

and use it again at that position.

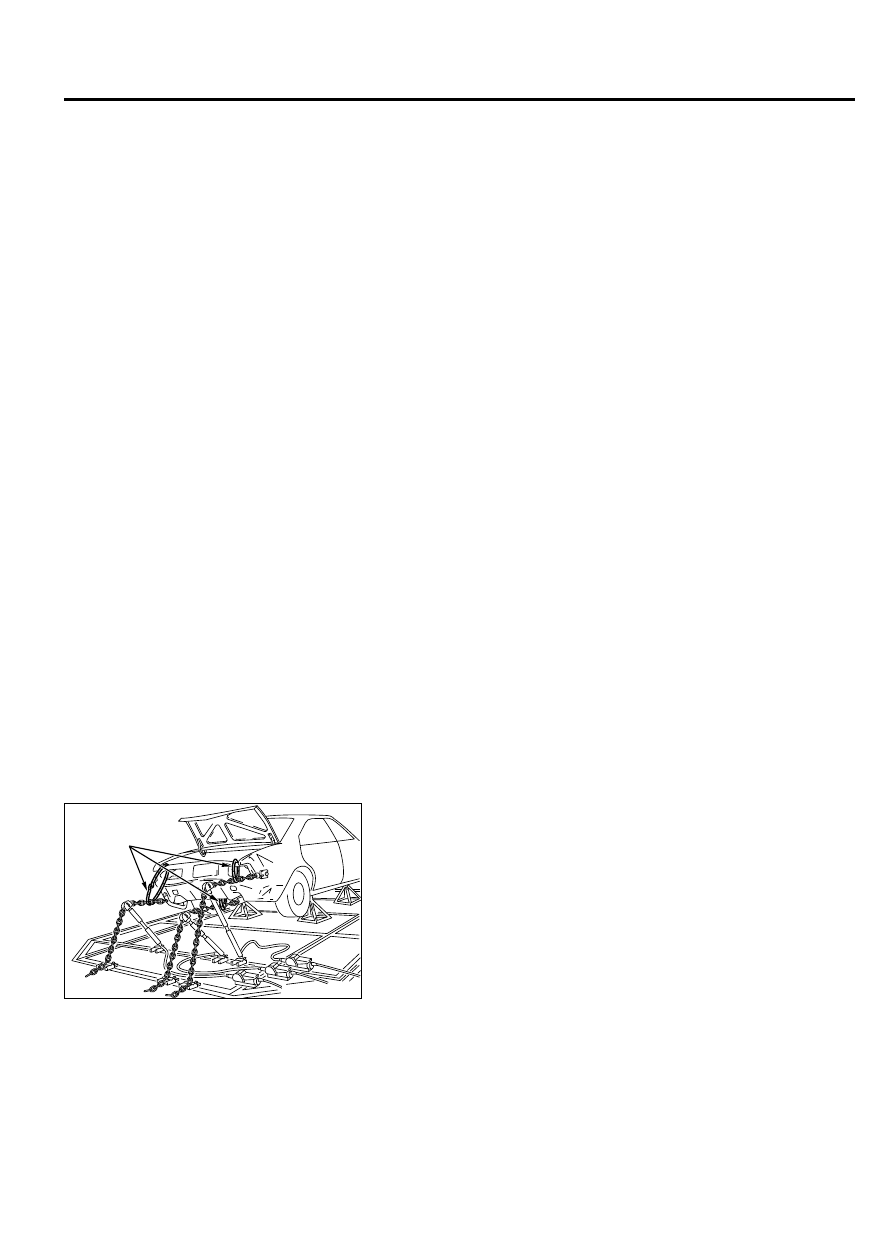

FRAME STRAIGHTENING NOTES

ZB6002470000

Wires for

protection

⦆

For safety, no one must be standing in the direction of the pull.

⦆

Wires or chains should be used for protection in the event of

an accident.

⦆

For frame straightening of body with frame, care should be

taken regarding the position (body mount) of installation to the

frame. The reason for this is that usually mounting rubber

pieces are used at the installation part in order to improve

vibration prevention, and these mounting rubber pieces might

be deformed if there is a deviation of the installation position.

BASE OF BODY REPAIR

9-27

BODY REPAIR