Mitsubishi Outlander GS45X. Manual - part 896

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-517

.

CIRCUIT OPERATION

• The ECM (terminal No. 114) supplies a 5-volt ref-

erence signal to the fuel tank differential pressure

sensor (terminal No. 3). The fuel tank differential

pressure sensor (terminal No. 2) is grounded

through the ECM (terminal No. 113).

• The fuel tank differential pressure sensor (termi-

nal No. 1) returns a voltage signal to the ECM

(terminal No. 112) that is proportional to the pres-

sure in the fuel tank.

.

TECHNICAL DESCRIPTION

• The ECM monitors the fuel tank differential pres-

sure sensor output voltage.

• The ECM determines whether the fuel tank differ-

ential pressure sensor signal voltage is within

normal operating parameters.

.

DESCRIPTIONS OF MONITOR METHODS

• Compare purge solenoid status with fuel tank dif-

ferential pressure sensor output voltage.

.

MONITOR EXECUTION

• Continuous.

.

MONITOR EXECUTION CONDITIONS

(OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored

in memory for the item monitored below)

• Evaporative emission purge solenoid monitor

• Evaporative emission ventilation solenoid monitor

• Fuel temperature sensor monitor

• Fuel level sensor monitor

Sensor (The sensors below are determined to be

normal)

• Mass airflow sensor

• Barometric pressure sensor

• Intake air temperature sensor

• Engine coolant temperature sensor

• Accelerator pedal position sensor

.

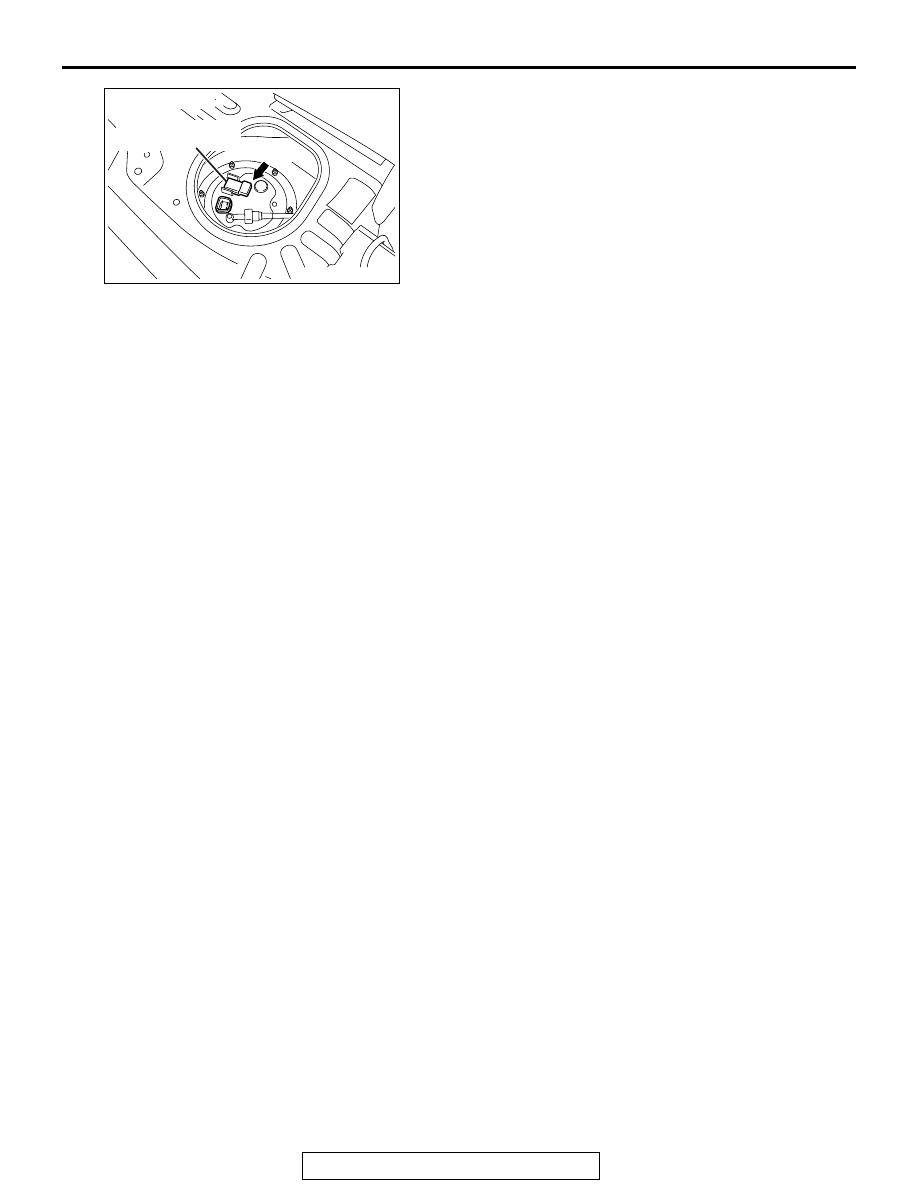

AK704189

Fuel tank differential

pressure sensor

D-19

Connector: D-19

AB