Mitsubishi Outlander GS45X. Manual - part 778

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-45

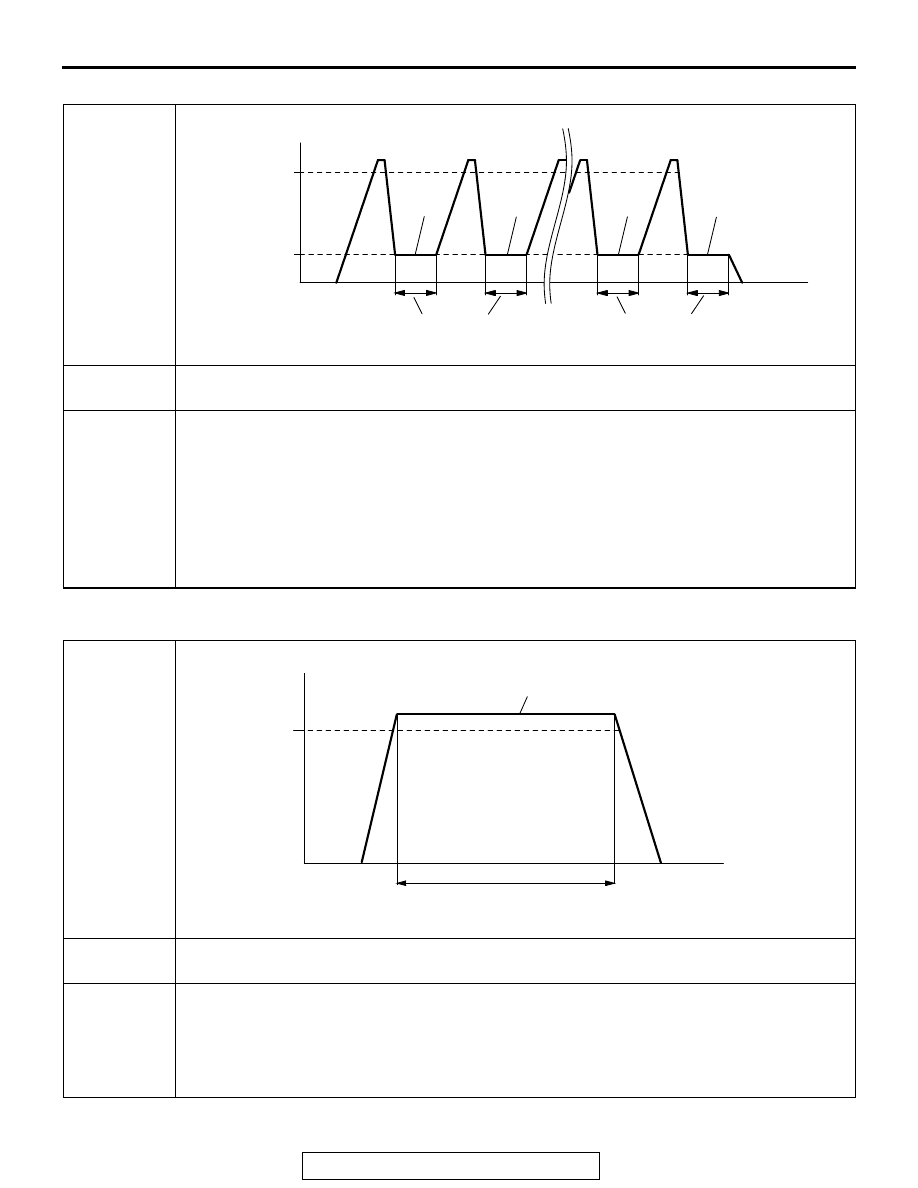

PATTERN 16

.

PATTERN 17

.

Drive cycle

pattern

Inspection

condition

Condition of A/T: Selector lever "D" range

Test

procedure

1. Start the engine with all the accessories switched OFF.

2. Accelerate until the vehicle speed is more than 50 km/h (31 mph).

3. Stop the vehicle in a safe place and let the engine idle for 20 seconds. (During the

monitor)

4. Repeat Steps 2 and 3 for 10 times.

5. Stop the vehicle in a safe place and turn the ignition switch to "LOCK" (OFF) position.

6. Start the engine and do Steps 1 to 5 again.

7. Confirm that the diagnostic trouble code (DTC) is not output.

AK402438

(3)

(2)

(1)

20 seconds

1st

mon-

itor

9th

mon-

itor

10th

mon-

itor

2nd

mon-

itor

Ignition

switch:

"LOCK" (OFF)

50 km/h

(31 mph)

Vehicle speed

AC

(3)

(2)

(2)

(3)

(3)

(2)

(5)

Idling

(2)

20 seconds

Time

Drive cycle

pattern

Inspection

conditions

• Engine coolant temperature: More than 20°C (68°F)

• Condition of A/T: Selector lever "D" range

Test

procedure

1. Start the engine with all the accessories switched OFF.

2. Drive the vehicle at more than 50 km/h (31 mph) for 30 seconds. (During the monitor)

3. Stop the vehicle in a safe place and turn the ignition switch to "LOCK" (OFF) position.

4. Start the engine and do Steps 1 to 3 again.

5. Confirm that the diagnostic trouble code (DTC) is not output.

AK402441

(2)

(1)

(3)

30 seconds

During the monitor

50 km/h

(31 mph)

Ignition

switch:

"LOCK" (OFF)

Vehicle speed

AP

Time