Mitsubishi Outlander GS45X. Manual - part 772

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-21

CONFIRMATION METHOD

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

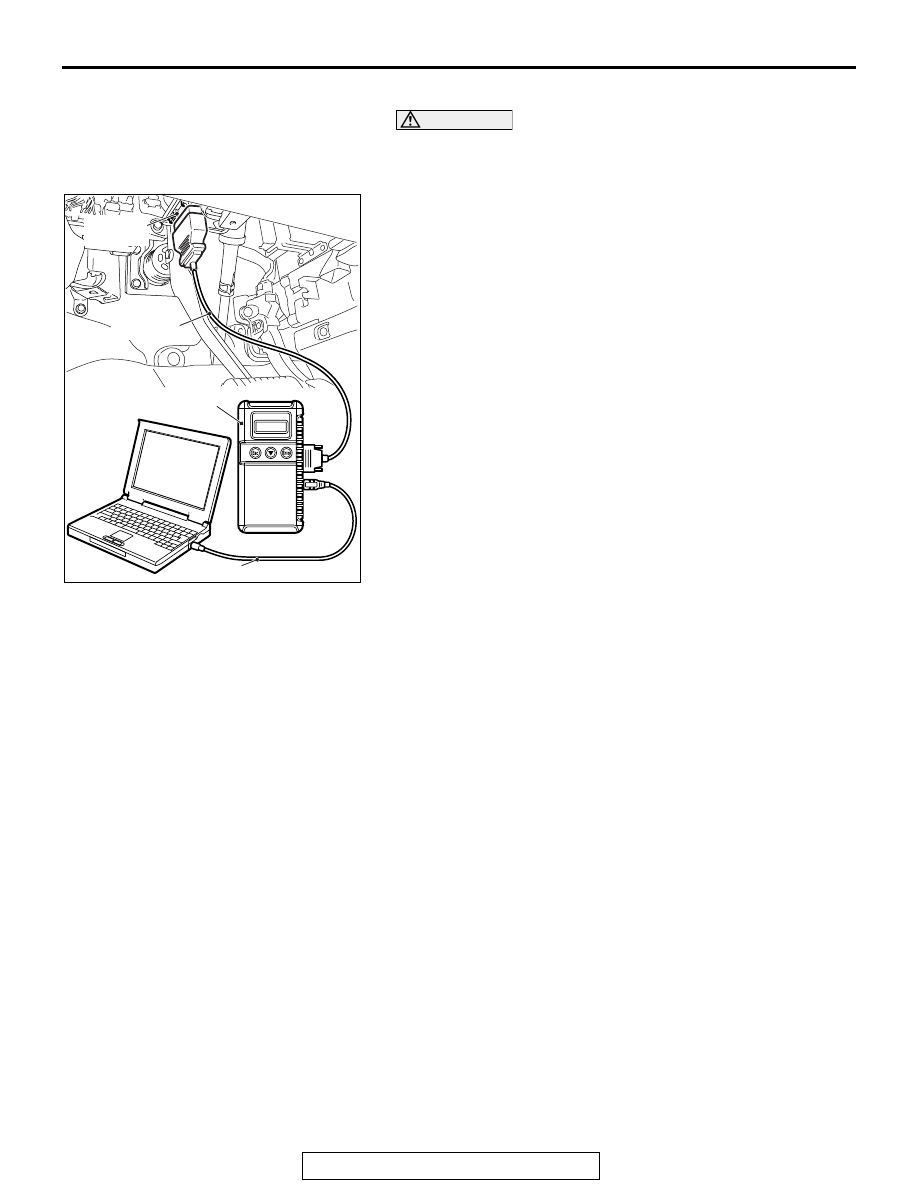

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "System select."

4. Choose "from 2006 MY" under "MODEL YEAR".

5. Check that "Vehicle Information" contents are correct.

6. Choose "MFI".

7. Select "Special Function" from MFI Screen.

8. Select "Provisional DTCs" from Special Function Screen.

PERMANENT DTC

The permanent DTC(PDTC) is stored in the EEPROM of the

engine control module (ECM) as the permanent status, which

checks that the malfunction of the emission related compo-

nents/ the system has not been repaired yet. When detecting

the malfunction necessary to illuminate the malfunction indica-

tor lamp (SERVICE ENGINE SOON or Check Engine Lamp),

the ECM illuminates the MIL and stores the appropriate DTC as

the permanent DTC in the EEPROM concurrently. The usual

DTC is stored in the EEPROM aside from this. The ECM can

store up to 6 PDTCs. The ECM, therefore, cannot store the 7th

and subsequent PDTCs. If the temporary malfunction causes

the malfunction indicator lamp to be illuminated and then the

reinstatement during the subsequent driving causes it to be

extinguished, the PDTC is erased. Also if the ECM checks that

the DTC malfunction is fixed during the driving after the DTC

repair is completed, the PDTC is erased. The permanent DTC,

however, is not erased by disconnecting the battery terminal or

erasing with the scan tool (M.U.T-III). The permanent DTC can

be erased if all readiness statuses are erased or not completed

at the time of reprogramming the ECM. If must be erased while

the vehicle is repaired, the PDTC can be erased by the proce-

dures shown below. If must be erased because of the failure to

pass the Inspection and Maintenance (I/M) test, the permanent

DTC can also be erased by the following procedure:

.

AK700568AB

MB991824

MB991827

MB991910

Data link

connector