Mitsubishi Outlander GS45X. Manual - part 769

SPECIAL TOOL

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-9

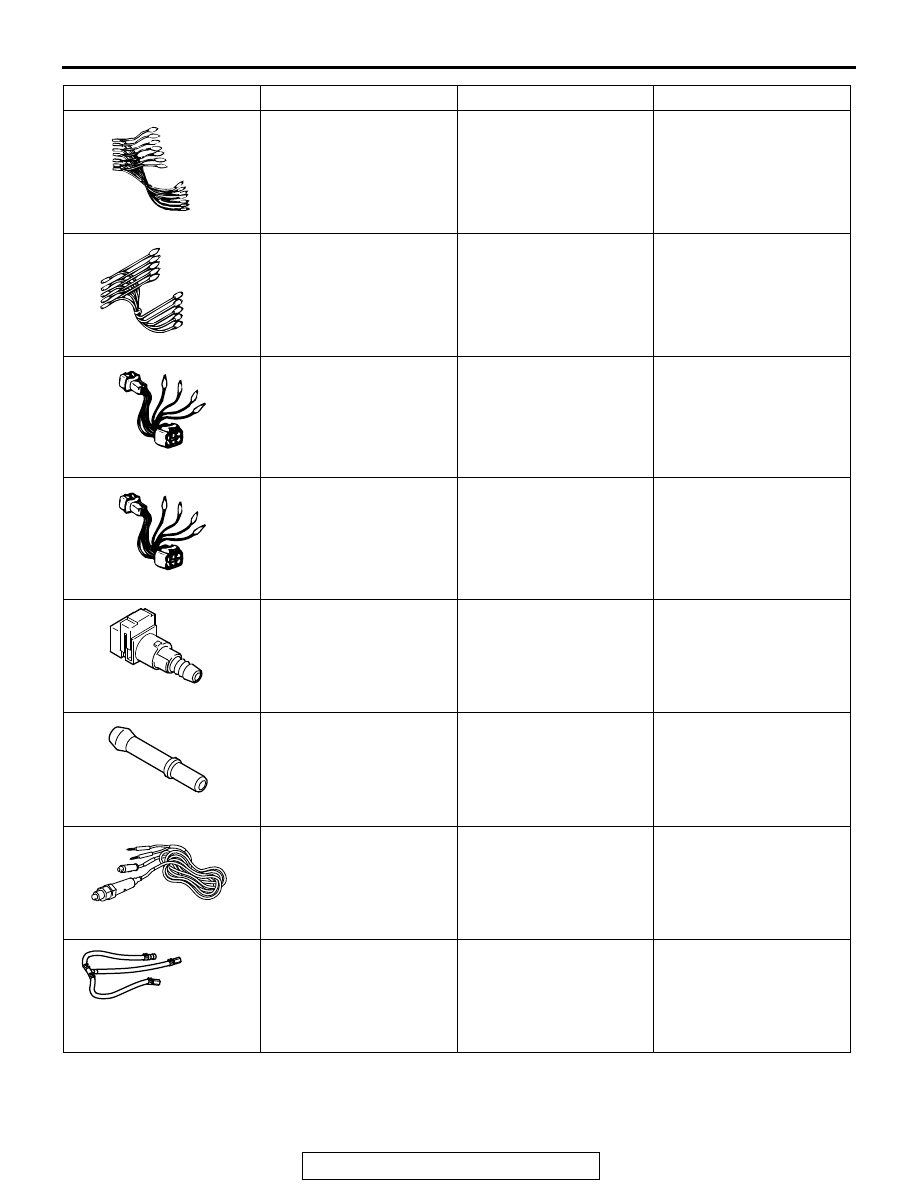

MB991709

Test harness

MB991709-01

Inspection using an

oscilloscope

MB991658

Test harness

Tool not available

• Inspection using an

oscilloscope

• Inspection of heated

oxygen sensor

• Inspection of engine

oil control valve

MD998464

Test harness (4 pin,

square)

MD998464-01

Inspection of heated

oxygen sensor

MB991316

Test harness (4 pin,

square)

Tool not available

Inspection of heated

oxygen sensor

MB992049

MB992049-01

Measurement of fuel

pressure

MB992001

Hose adaptor

-

Measurement of fuel

pressure

MB991981

Fuel pressure gauge set

Tool not available

Measurement of fuel

pressure

MB992076

Injector test set

-

Measurement of fuel

pressure

Tool

Tool number and name Supersession

Application

MB991658

MB992049

MB992001

MB991981

MB992076