Mitsubishi Outlander GS45X. Manual - part 675

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-523

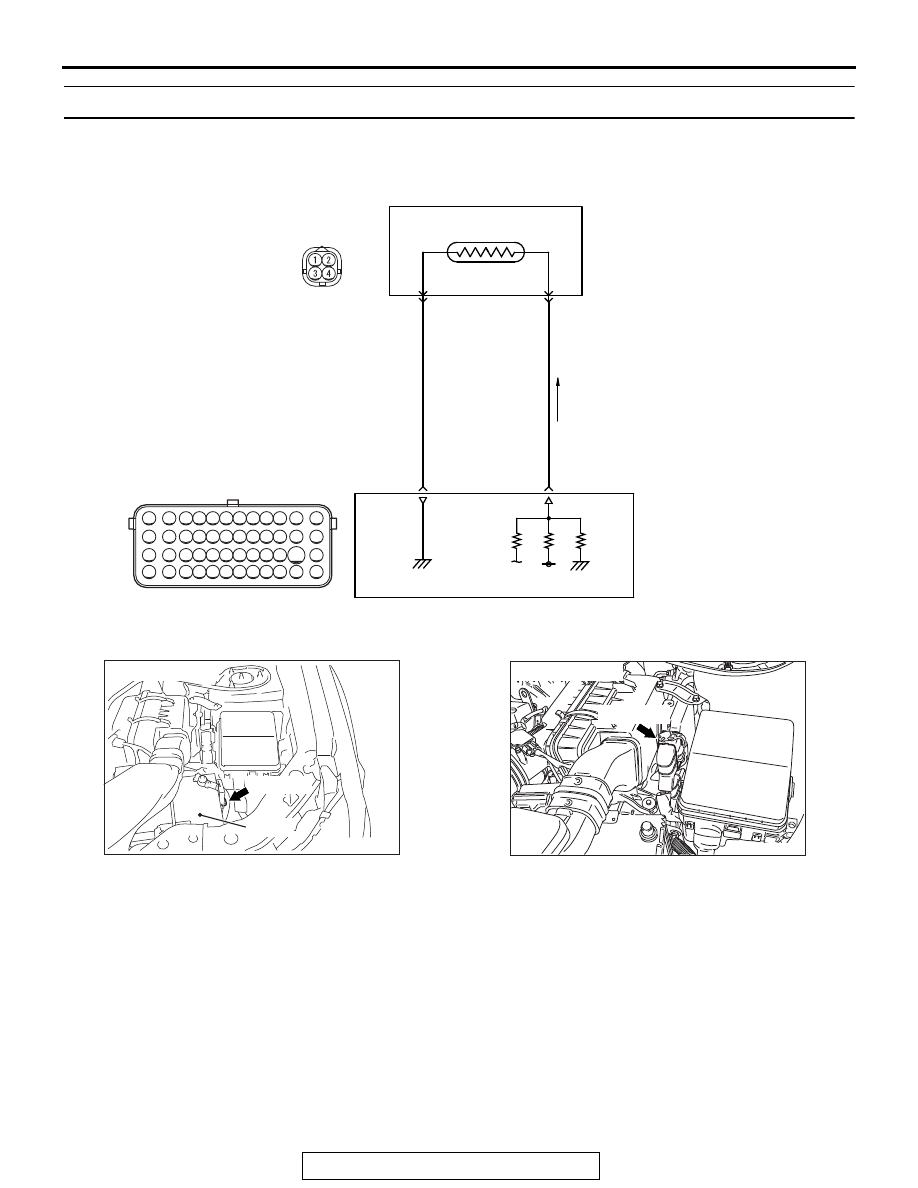

DTC P0515: Battery Temperature Sensor Circuit

.

CIRCUIT OPERATION

• Approximately 5 volts are applied to the battery

temperature sensor output terminal (terminal No.

2) from the ECM (terminal No. 98) via the resistor

in the ECM. The ground terminal (terminal No. 3)

is grounded with ECM (terminal No. 101).

• The battery temperature sensor is a negative

temperature coefficient type of resistor. When the

battery temperature rises, the resistance

decreases.

• The battery temperature sensor output voltage

increases when the resistance increases and

decreases when the resistance decreases.

.

TECHNICAL DESCRIPTION

• The battery temperature sensor converts the bat-

tery temperature to a voltage.

• The ECM checks whether this voltage is within a

specified range.

.

DESCRIPTIONS OF MONITOR METHODS

Battery temperature sensor output voltage is out of

specified range.

.

AKA00474

71 72 73 74 75 76 77 78 79 80 81 82

83 84 85 86 87 88 89 90 91 92 93 94

95 96 97 98 99

100 101 102 103 104

112 113 114

109

108

107

110 111

115 116

106

105

118

117

101

98

BATTERY TEMPERATURE

SENSOR (INTEGRATED IN

BATTERY CURRENT SENSOR)

3

2

5 V

BATTERY TEMPERATURE SENSOR CIRCUIT

A-65

B-11

ENGINE

CONTROL

MODULE

GRA

Y

BLUE-BLA

CK

AC

AK900202 AF

A-65 (GR)

Connector: A-65

Battery

AK704097AB

Connector: B-11

B-11 (GR)