Mitsubishi Outlander GS45X. Manual - part 563

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-75

DTC SET CONDITIONS

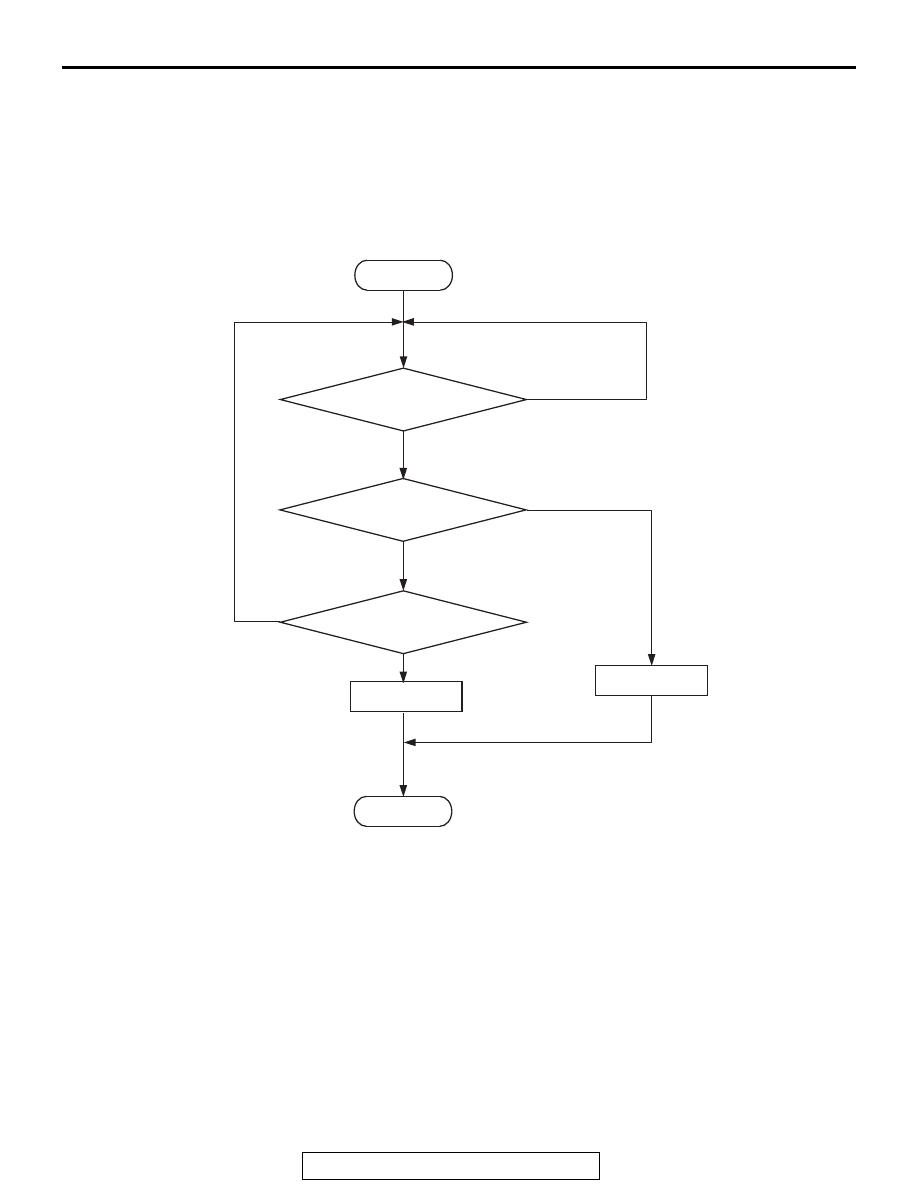

Logic Flow Chart

Check Conditions

• More than 20 seconds have passed since the

engine starting sequence was completed.

• Engine speed is 1,188 r/min or more.

• Engine coolant temperature is higher than 76°C

(169

°F).

Judgment Criterion

• The difference between the actual exhaust valve

closing timing and the exhaust valve target clos-

ing timing is more than 5 degrees for 5 seconds.

.

OBD-II DRIVE CYCLE PATTERN

• Refer to Diagnostic Function − OBD-II Drive

Cycle

− Pattern 20

.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

• Exhaust engine oil control valve failed.

• Oil passage of variable valve timing control sys-

tem clogged.

• Exhaust variable valve timing sprocket operation

mechanism stuck.

• ECM failed.

AK604305

Start

Yes

Yes

Yes

No

No

No

|Cam angle-target|

> 5˚CA

Continuous

failure for 5secs

Malfunction

End

Good

Monitoring

conditions