Mitsubishi Outlander GS45X. Manual - part 391

ON-VEHICLE SERVICE

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-185

3. Confirm that the selector lever is in the "N" position, and

then start the engine.

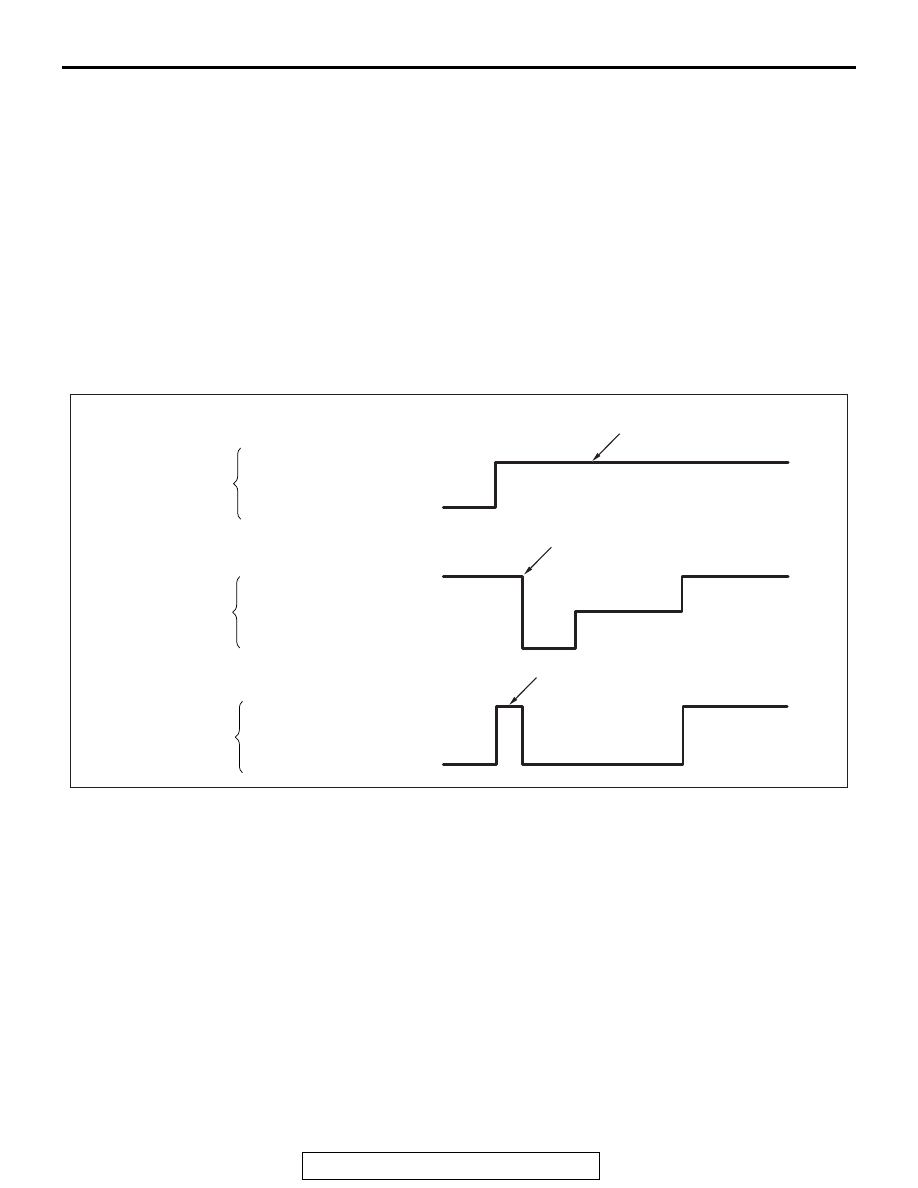

4. When carrying out the actuator tests No. 01 to 04, perform

the actuator tests using scan tool while depressing the brake

pedal. When carrying out the actuator tests, rotate the wheel

by hands to confirm that the braking force changes.

NOTE:

.

•

While performing the actuator test, the ABS warning light

flashes at a rate of 2 Hz.

•

When ABS-ECU is disabled due to the fail-safe function,

the scan tool actuator test cannot be performed.

•

After the actuator test has been performed, the ABS

warning light and brake waning light illuminate until the

ignition switch is turned to ON again or the communica-

tion between scan tool and ABS-ECU is terminated.

5. This is indicated as shown in the above.

6. When any malfunction has been found, take a necessary

action according to the "Judgment Table."

AC608801

M.U.T.-III actuator test

(No.01, 02, 03, 04) start

M.U.T.-III actuator test

(No.01, 02, 03, 04)

M.U.T.-III actuator test

(No.01, 02, 03, 04)

Pedal operation

Depressed

Released

Solenoid valve position

Increase in pressure

Steady pressure

Reduction in pressure

Checking the brake force

Lock

Drag force when the pedal is free

Approx.

1 second

Approx.

2 seconds

Approx.

3 seconds

AC