Content .. 1243 1244 1245 1246 ..

Mitsubishi Outlander GS45X. Manual - part 1245

CYLINDER HEAD AND VALVES

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-55

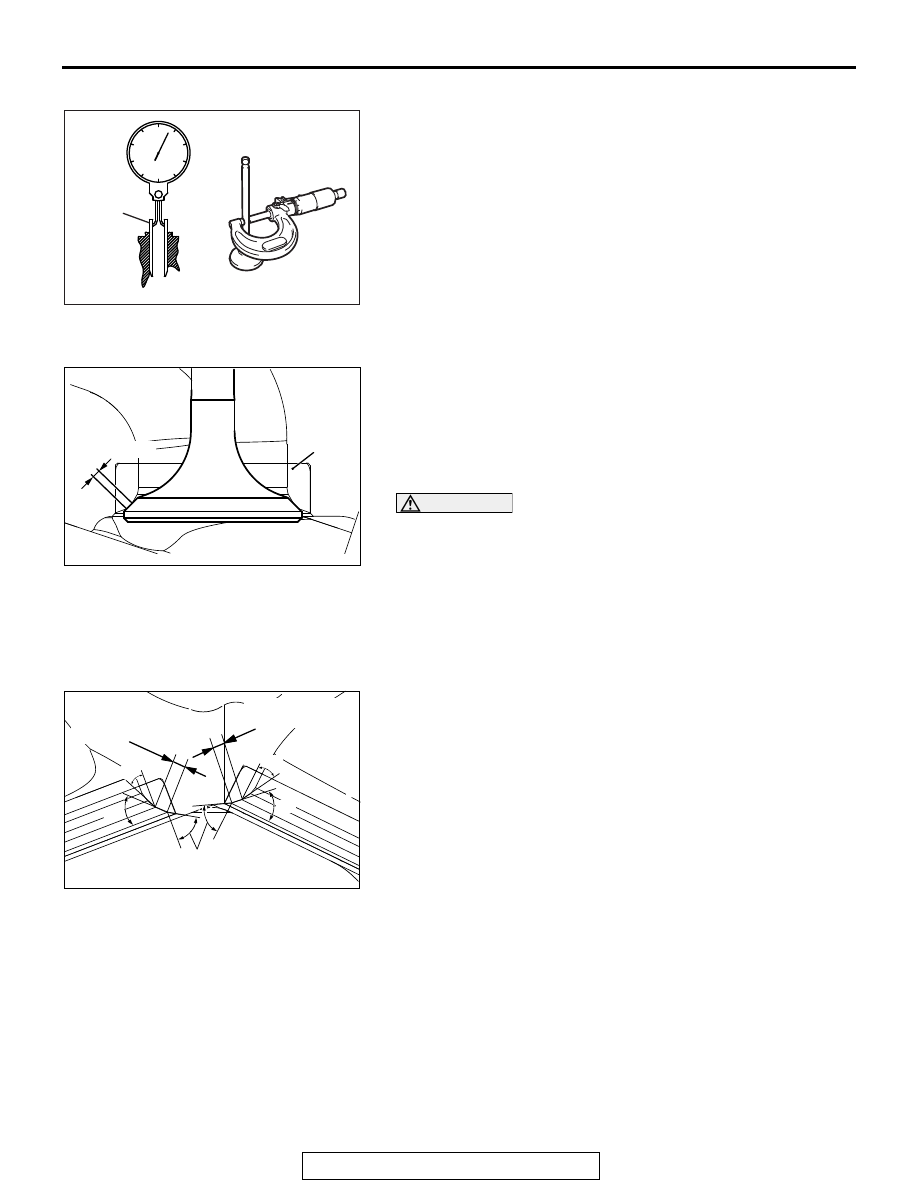

VALVE GUIDE

Measure clearance between the valve guide and valve stem. If

the clearance exceeds the limit, replace the valve guide or

valve, or both.

Standard value:

Intake 0.020

− 0.047 mm (0.0008 − 0.0019 inch)

Exhaust 0.030

− 0.054 mm (0.0012 − 0.0021 inch)

Limit:

Intake 0.10 mm (0.0039 inch)

Exhaust 0.11 mm (0.0043 inch)

.

VALVE SEAT

Assemble the valve, then measure the contact width. If the

measurement exceeds the specified limit, replace the valve

seat.

Standard value

Intake: 1.16

− 1.46 mm (0.046 − 0.058 inch)

Exhaust: 1.35

− 1.65 mm (0.053 − 0.065 inch)

CAUTION

If the variation in the width exceeds 0.2 mm even if the

contact width is within the standard value, replace or cor-

rect the valve sheet.

REPAIR PROCEDURE OF VALVE SEAT

1. Check clearance between valve guide and valve and

replace the valve guide if necessary before repairing the

valve seat.

2. Repair the valve seat so that seat width and seat angle are

to the specified shape.

3. Lap valve and valve seat with lapping compound after

repairing valve seat.

AK300168

Guide inside diameter

Stem diameter

Valve

guide

AF

AK601281AD

Contact width

Valve seat

AK503333AE

30˚

60˚

30˚

1.16 – 1.46 mm

(0.046 – 0.058 in)

45˚

45˚

1.35 – 1.65 mm

(0.053 – 0.065 in)