Content .. 1241 1242 1243 1244 ..

Mitsubishi Outlander GS45X. Manual - part 1243

CAMSHAFT

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-47

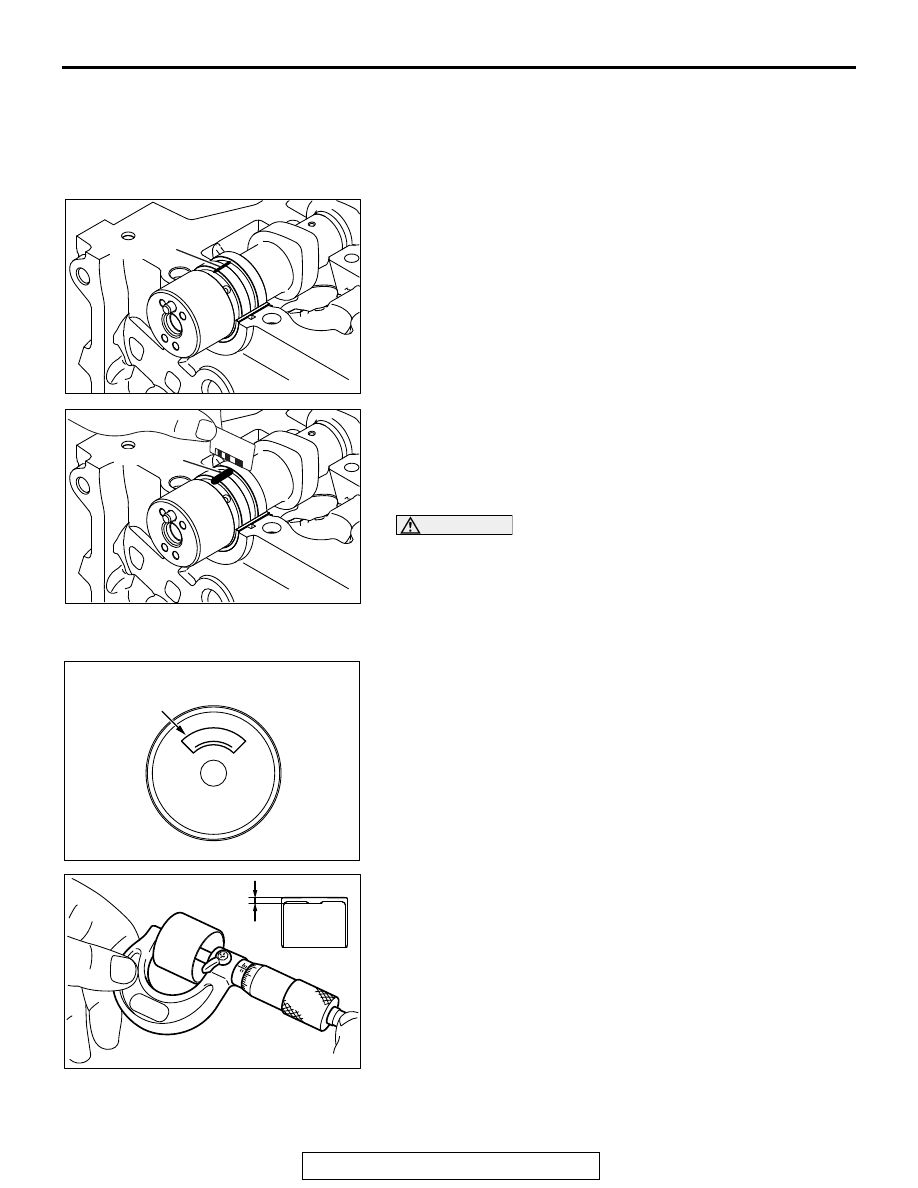

CAMSHAFT OIL CLEARANCE (PLASTIGAGE

METHOD)

1. Thoroughly wipe oil on the outside diameter of the camshaft

and the inside diameter of the bearing.

2. Install the bearing to the camshaft.

3. Put straightly the plastigage having the length of the bearing

width on the journal axis, centering the axis.

4. Carefully install the bearing cap.Tighten the bolt as

instructed in >>B<< Bolt Installation Point.

5. Remove the bolt and the bearing cap carefully.

6. Measure the plastigage whose width is most compressed

using the scale printed on the plastigage bag. When the

measured value deviates from the standard one, replace the

bearing.

Standard value: 0

− 0.032 mm (0.0013 inch)

CAUTION

When the bearing is used again, be careful not to reverse

the cylinder head side and the camshaft side at the instal-

lation.

.

VALVE TAPPET

1. Check the thickness stamp.

2. If the measured value in the table value is not in agreement

with the value in the table to the thickness stamp, replace

the valve tappet.

There are 47 kinds of valve tappets at intervals of 0.015 mm

(0.0006 inch) in the range between 3.000 (0.1181 inch) and

3.690 mm (0.1453 inch).

AK503390

Plastigage

AC

AK503391

Plastigage

AC

0

0

3

0

.

AK703500AF

Thickness stamp

Under view

AK304938

AB

Wall

thickness