Content .. 1228 1229 1230 1231 ..

Mitsubishi Outlander GS45X. Manual - part 1230

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-73

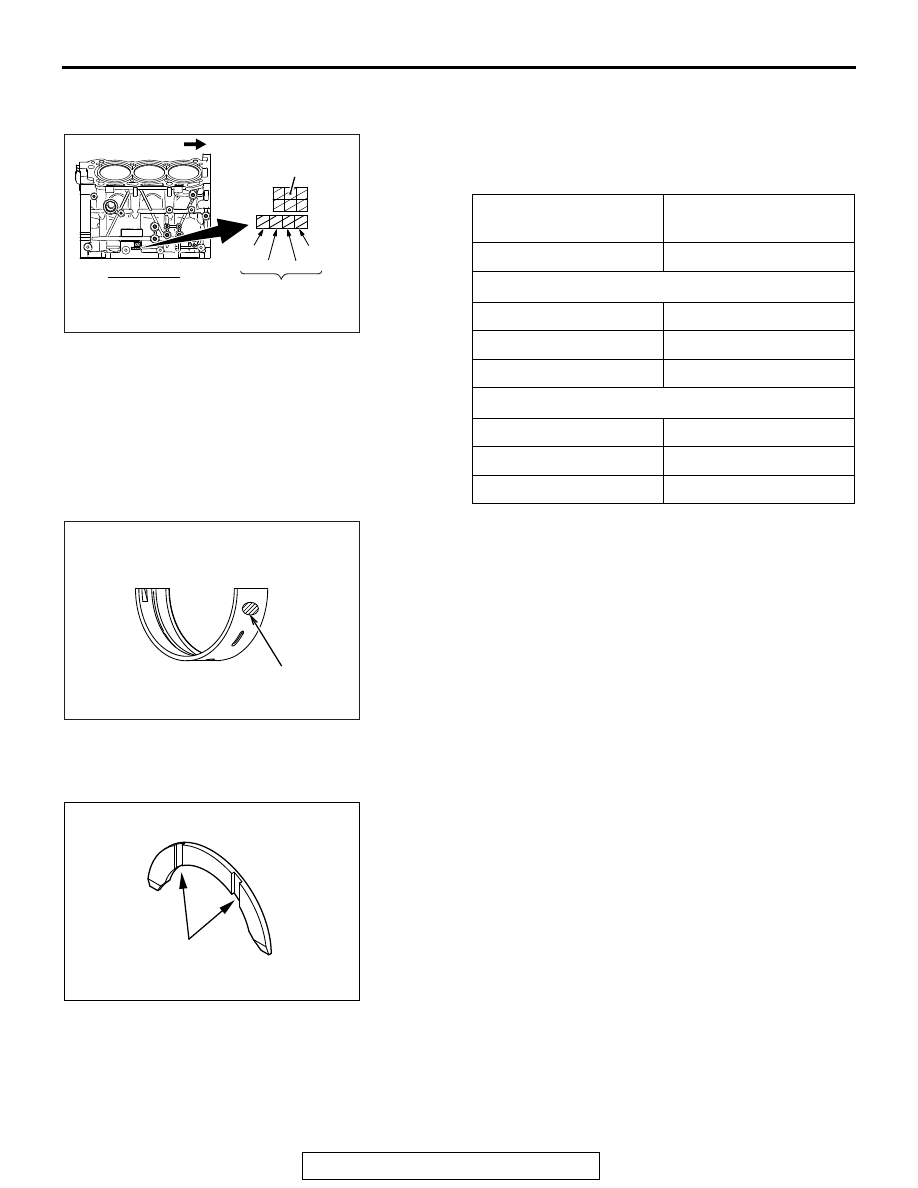

>>B<< CRANKSHAFT BEARING UPPER

INSTALLATION

1. If the upper crankshaft bearing is replaced, select based on

the identification mark of cylinder block (illustrated) and the

table shown below.

2. The upper crankshaft bearing has the identification mark on

the location shown in the illustration.

3. Install the upper selected crankshaft bearing.

.

>>C<< CRANKSHAFT THRUST BEARING

INSTALLATION

1. Install the thrust bearing in the Number3 bearing bore in the

cylinder block and in the bearing cap. For easier installation,

apply engine oil to the bearings; this will help hold them in

position.

2. The thrust bearings must be installed with their groove

toward the crankshaft web.

.

Crankshaft journal

(Upper)

Crankshaft bearing

Identification mark

Identification mark

Number 1 and 4 journal

1

1

2

2

3

3

Number 2 and 3 journal

0

0

1

1

2

2

AK600832

Right side

Timing belt side

Cylinder

bore size

Crankshaft journal (Upper)

identification mark

No.4

No.3 No.2

No.1

AC

AK600833AC

Identification

mark

AK600798AC

Groove