Content .. 1227 1228 1229 1230 ..

Mitsubishi Outlander GS45X. Manual - part 1229

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-69

PISTON AND CONNECTING ROD INSPECTION

M1113008501647

.

PISTON RING INSPECTION

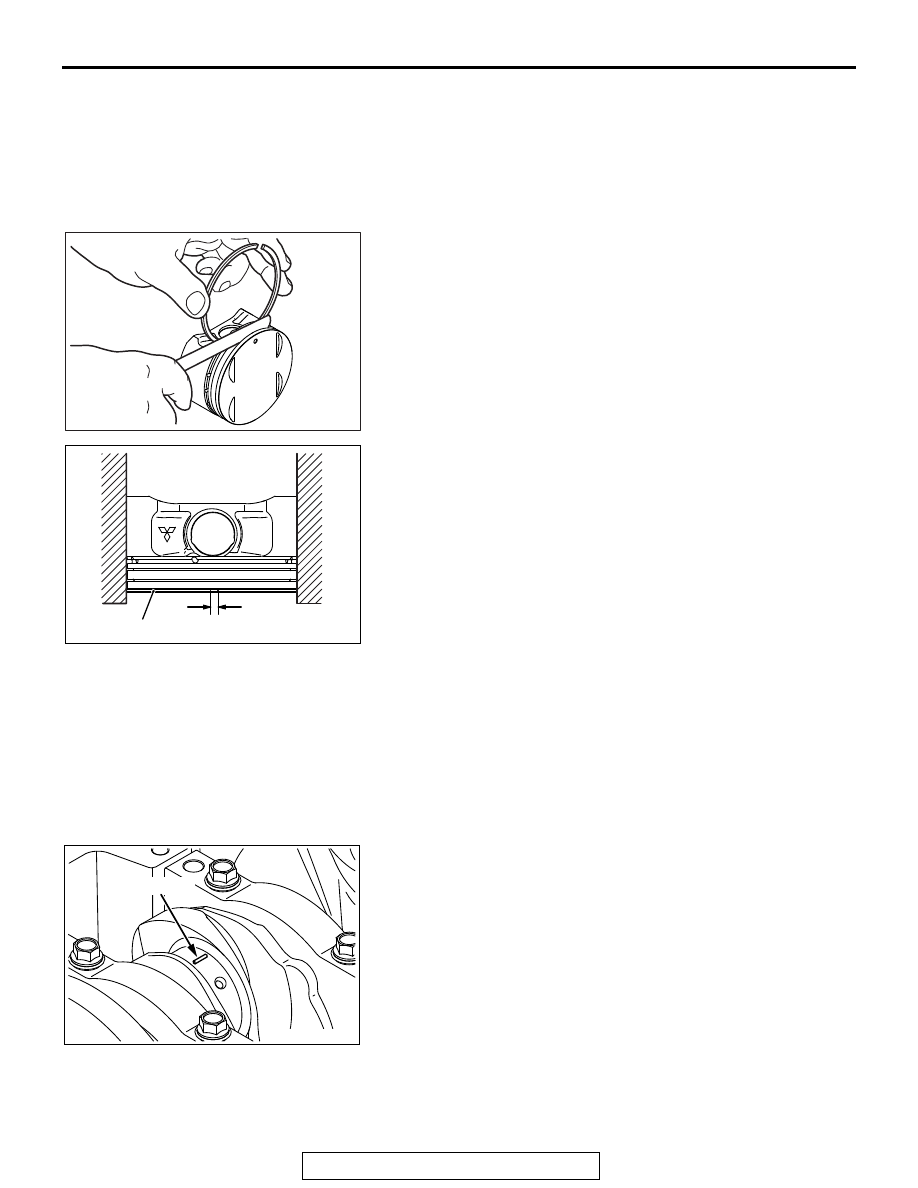

1. Check the piston ring for damage, excessive wear, and

breakage. Replace if defects are evident. If the piston has

been replaced with a new one, the piston rings must also be

replaced with new ones.

2. Check for clearance between the piston ring and ring

groove. If the limit is exceeded, replace the ring or piston, or

both.

Standard value:

Number 1: 0.04

− 0.08 mm (0.0016 − 0.0031 inch)

Number 2: 0.03

− 0.07 mm (0.0012 − 0.0027 inch)

Limit: 0.1 mm (0.004 inch)

3. Insert the piston ring into the cylinder bore. Force the ring

down with a piston, the piston crown being in contact with

the ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a feeler gauge.

If the ring gap is excessive, replace the piston ring.

Standard value:

Number 1: 0.18

− 0.33 mm (0.008 − 0.012 inch)

Number 2: 0.28

− 0.48 mm (0.012 − 0.018 inch)

Oil: 0.10

− 0.60 mm (0.004 − 0.023 inch)

Limit:

Number 1, Number 2: 0.8 mm (0.03 inch)

Oil: 1.0 mm (0.04 inch)

.

CRANKSHAFT PIN OIL CLEARANCE

<PLASTIGAGE METHOD>

The crankshaft oil clearance can be measured easily by using

plastigage method, as follows:

1. Remove oil from the crankshaft pin and the bearing inner

surface.

2. Cut plastigage to the same length as the width of the

bearing and place it on the pin in parallel with its axis.

3. Install the connecting rod cap carefully and tighten the nuts

to the specified torque.

4. Carefully remove the connecting rod cap.

AK600927

AK600928 AC

Push in by piston

Piston ring gap

Piston ring

AK600906

Plastigage

AC