Content .. 1206 1207 1208 1209 ..

Mitsubishi Outlander GS45X. Manual - part 1208

MAINTENANCE SERVICE

TSB Revision

GENERAL

00-75

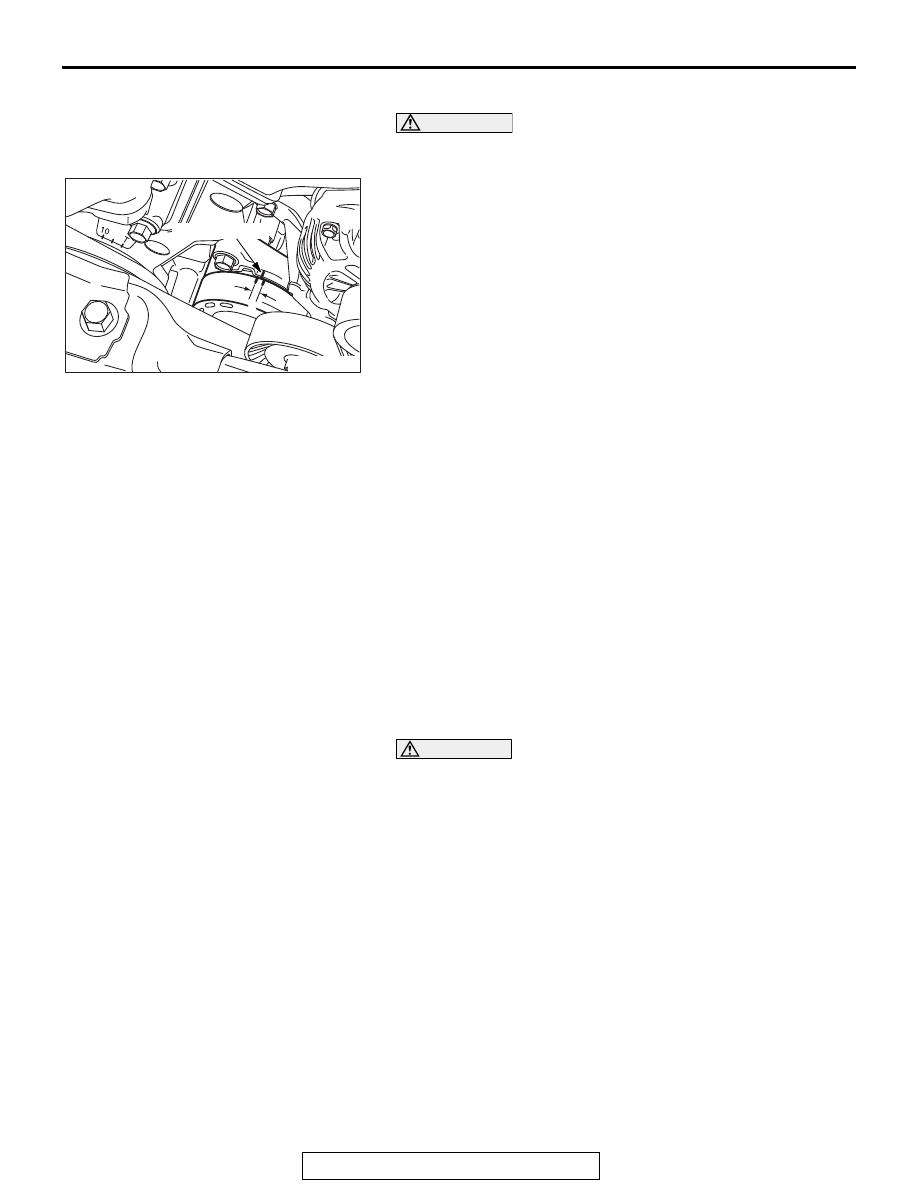

<3.0L ENGINE>

CAUTION

Check the drive belt tension after turning the crankshaft

clockwise one turn or more.

1. Make sure that the indicator mark is within the area marked

with A in the illustration.

2. If the mark is out of the area, replace the drive belt. (Refer to

).

NOTE: The drive belt tension adjustment is not necessary,

as the engine is equipped with an auto-tensioner.

9. EXHAUST SYSTEM (CONNECTIONS PORTION

OF MUFFLER, MUFFLER PIPES AND

CONVERTER HEAT SHIELDS) (CHECK AND

SERVICE AS REQUIRED)

M1001005800471

1. Check for holes and exhaust gas leaks due to damage,

corrosion, etc.

2. Check the joints and connections for looseness and exhaust

gas leaks.

3. Check the rubber hangers and brackets for damage.

10. ENGINE OIL (CHANGE)

M1001002600809

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80

− 90°C (176 −

194

°F).

WARNING

Use care as oil could be hot.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

AK700055 AB

Indicator mark

A