Mitsubishi Outlander GS45X. Manual - part 68

FOG LIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-269

STEP 6. Check the wiring harness between fog light (LH)

connector A-41or fog light (RH) connector A-51 (terminal

2) and fog light relay connector A-14X (terminal 3).

NOTE: Also check intermediate connector A-46 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector A-46 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection

.

• Check the power supply line for open circuit.

Q: Is the wiring harness between fog light (LH) connector

A-41 or fog light (RH) connector A-51 (terminal 2) and

fog light relay connector A-14X (terminal 3) in good

condition?

YES : Go to Step 7.

NO : Repair the wiring harness.

STEP 7. Retest the system.

Q: Does the right or left fog light illuminate in good

condition?

YES : The trouble can be an intermittent malfunction (Refer

to GROUP 00, How to use

Troubleshooting/inspection Service Points

− How to

Cope with Intermittent Malfunction

NO : Go to Step 1.

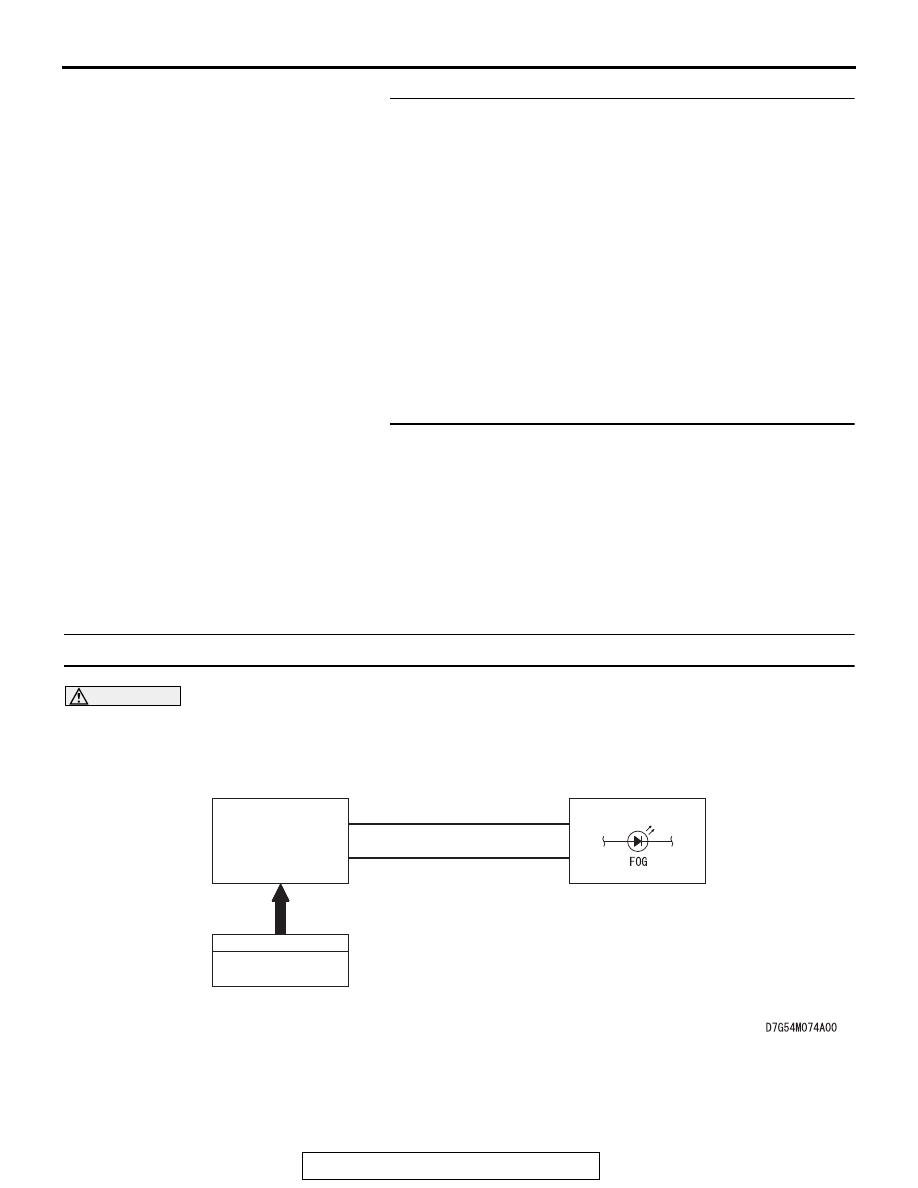

Inspection Procedure 3: Fog light indicator does not illuminate/go out normally.

CAUTION

Whenever the ECU is replaced, ensure that the

input and output signal circuits are normal.

.

TECHNICAL DESCRIPTION (COMMENT)

If the fog light indicator does not illuminate normally, connec-

tor(s), wiring harness in the CAN bus lines, the ETACS-ECU or

the combination meter may be defective.

AC703271

Fog Light Indicator Circuit

INPUT SIGNAL

ETACS-ECU

COMBINATION

METER

CAN COMMUNICATION LINE

(CAN_L LINE)

CAN COMMUNICATION LINE

(CAN_H LINE)

FOG LIGHT SWITCH

AB