Mitsubishi Outlander GS45X. Manual - part 52

HEADLIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-205

ON-VEHICLE SERVICE

HEADLIGHT AIMING

M1540100500490

PRE-AIMING INSTRUCTIONS (LOW-BEAM)

.

1. Inspect for rusted or faulty headlight assemblies.

2. These conditions must be corrected before a satisfactory

adjustment can be made.

3. Inspect tire inflation, and adjust if necessary.

4. If the fuel tank is not full, place a weight in the trunk of the

vehicle to simulate weight of a full tank [3 kg (6.6 pounds)

per gallon].

5. There should be no other load in the vehicle other than

driver or substituted weight of approximately 68 kg (150

pounds) placed in driver's position.

6. Turn the headlight leveling switch to the switch position "0."

<Vehicles with headlight manual leveling system>

7. Thoroughly clean headlight lenses.

8. Place the vehicle on a level floor, perpendicular to a flat

screen 7.62 m (25.0 ft) away from the bulb center-marks on

the headlight lens.

9. Rock vehicle sideways to allow vehicle to assume its normal

position.

10.Bounce the front suspension through three (3) oscillations

by applying the body weight to hood or bumper.

7012

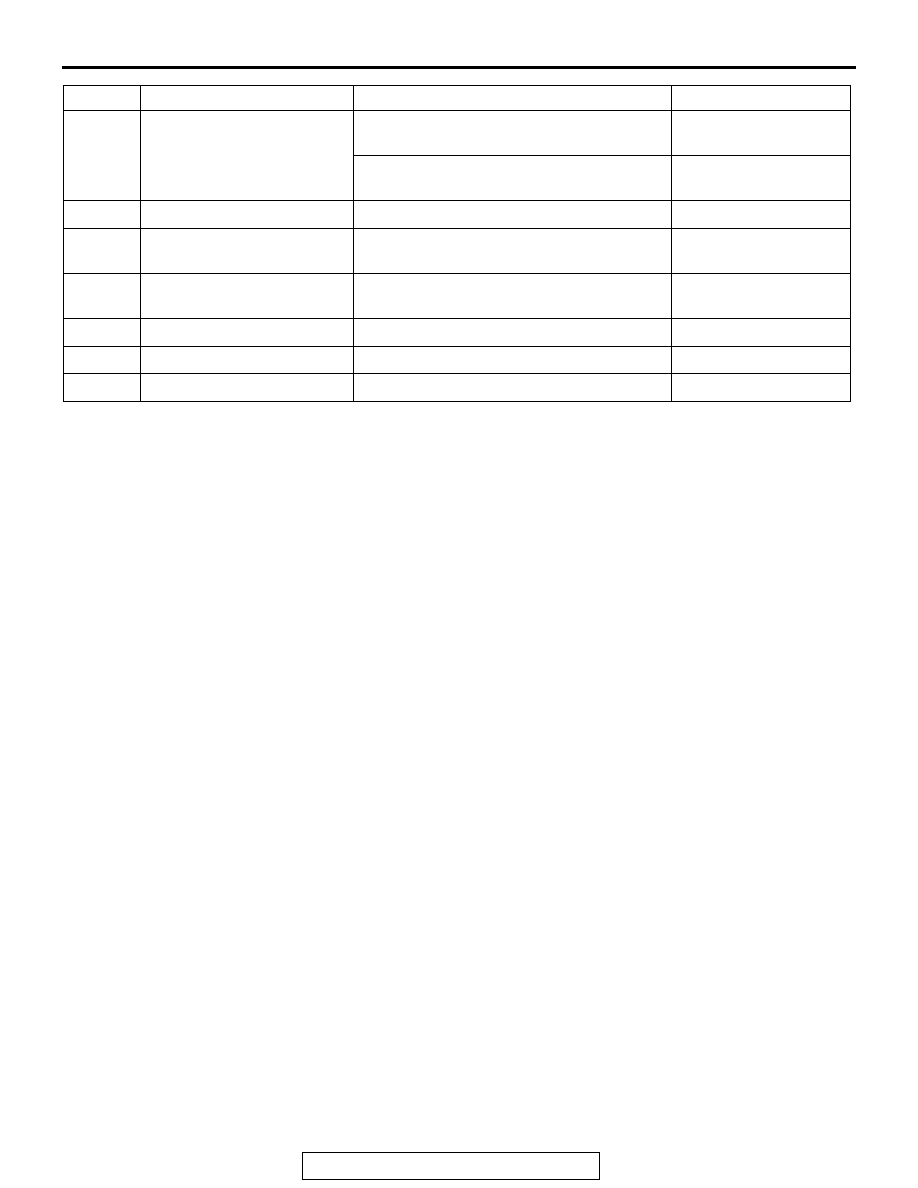

RLS Tunnel detect output

When the lighting control sensor area is

bright

OFF

When the lighting control sensor area is

dark

ON

7014

RLS specification

−

EU

7015

RLS ECU Diagnostic

Version

−

−

7016

RLS ECU Hardware

Version

−

−

7017

RLS ECU Software Version −

−

7018

RLS ECU Part number

−

8634A001

7019

RLS ECU Serial number

−

−

Item No. Scan tool display

Check conditions

Normal conditions