Mitsubishi Outlander (2013+). Manual - part 650

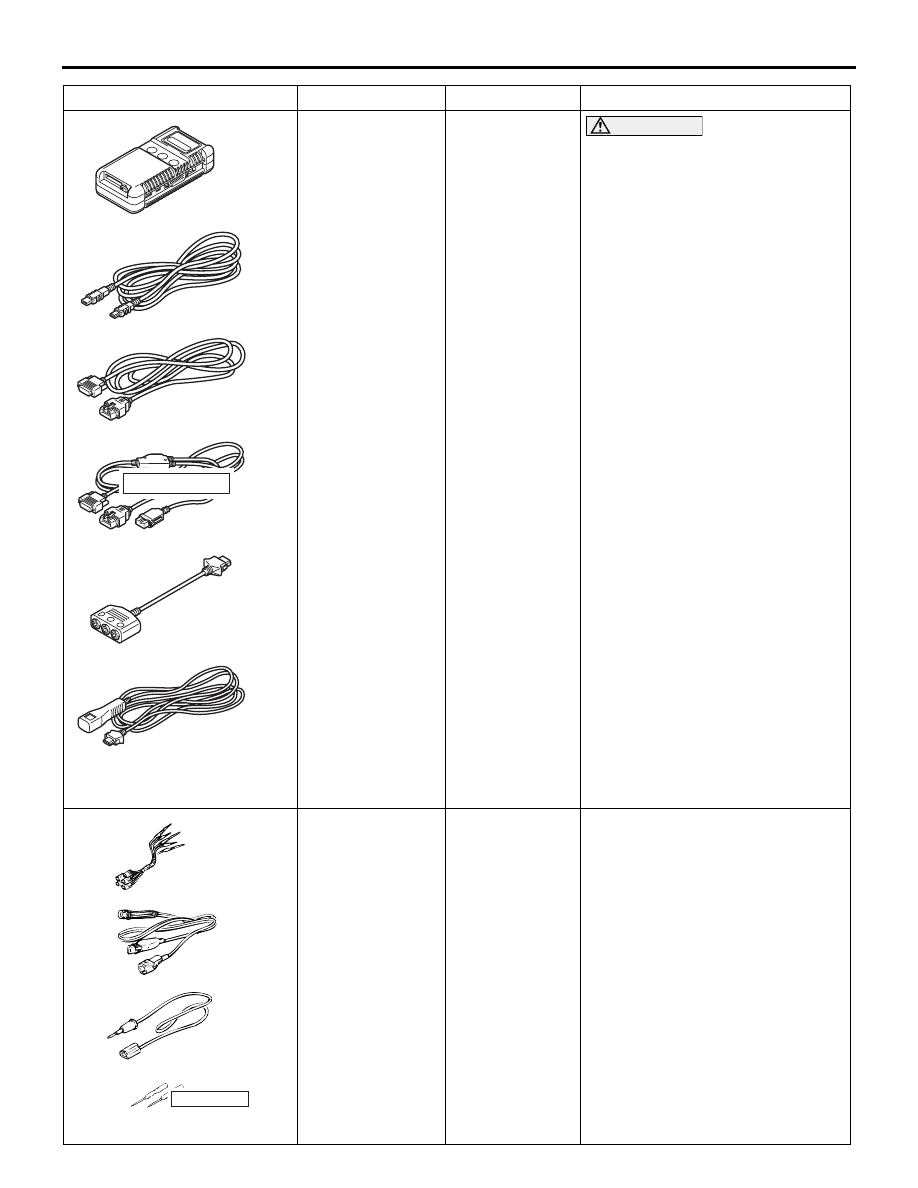

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

a

b

c

d

e

f

DO NOT USE

HEADLAMP

CHASSIS ELECTRICAL

54A-85

MB991955

a. MB991824

b. MB991827

c. MB991910

d. MB991911

e. MB991825

f. MB991826

M.U.T.-III

sub-assembly

a. Vehicle

Communicati

on Interface

(V.C.I.)

b. M.U.T.-III

USB cable

c. M.U.T.-III

main harness

A (Vehicles

with CAN

communicatio

n system)

d. M.U.T.-III

main harness

B (Vehicles

without CAN

communicatio

n system)

e. M.U.T.-III

measure

adapter

f. M.U.T.-III

trigger

harness

CAUTION

For vehicles with CAN

communication, use M.U.T.-III

main harness A to send

simulated vehicle speed. If you

connect M.U.T.-III main harness B

instead, the CAN communication

does not function correctly.

Diagnosis code, service data and

actuator test check.

MB991223

a

d

c

b

DO NOT USE

BA

MB991223

a. MB991219

b. MB991220

c. MB991221

d. MB991222

Harness set

a. Check

harness

b. LED harness

c. LED harness

adapter

d. Probe

Continuity check and voltage

measurement at harness wire or

connector

a. For checking connector pin

contact pressure

b. For checking power supply

circuit

c. For checking power supply

circuit

d. For connecting a locally sourced

tester

Tool

Number

Name

Use