Mitsubishi Outlander (2013+). Manual - part 638

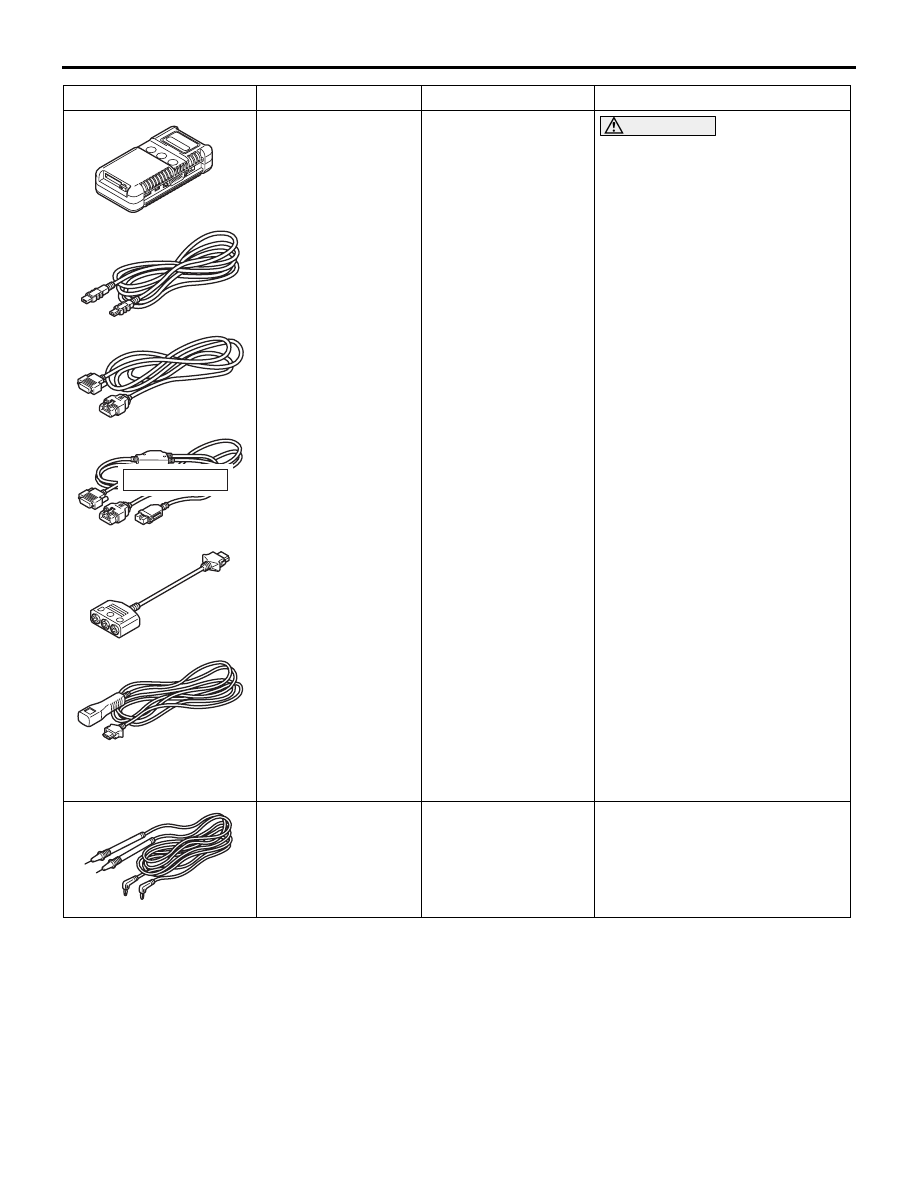

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

a

b

c

d

e

f

DO NOT USE

COMBINATION METER

CHASSIS ELECTRICAL

54A-37

MB991955

a. MB991824

b. MB991827

c. MB991910

d. MB991911

e. MB991825

f. MB991826

M.U.T.-III

sub-assembly

a. Vehicle

Communication

Interface (V.C.I.)

b. M.U.T.-III USB

cable

c. M.U.T.-III main

harness A

(Vehicles with CAN

communication

system)

d. M.U.T.-III main

harness B

(Vehicles without

CAN

communication

system)

e. M.U.T.-III measure

adapter

f. M.U.T.-III trigger

harness

CAUTION

For vehicles with CAN

communication, use M.U.T.-III

main harness A to send

simulated vehicle speed. If you

connect M.U.T.-III main harness

B instead, the CAN

communication does not

function correctly.

Combination meter (incorporating

the meter-ECU) check (Diagnosis

code, service data, actuator test)

MB991499

MB991499

Measurement probe

Measurements of voltage and

resistance value

NOTE: M.U.T.-II attached probe

(Commercial probes can also be

used.)

Tool

Number

Name

Use