Mitsubishi Outlander (2013+). Manual - part 464

TROUBLESHOOTING

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-31

STEP 8. Check for wheel bearing looseness

NOTE: Loose wheel bearing may increase the gap

between the wheel speed sensor and the wheel

speed detection magnet encoder. Check the wheel

bearing for looseness. <Refer to GROUP 26

−

Wheel

Bearing Axial Play Check . (front), GROUP 27A

−

Wheel Bearing Axial Play Check (rear-2WD) or

GROUP 27B

−

Wheel Bearing Axial Play Check

(rear-4WD)>

Q: Is the check result normal?

YES :

Go to Step 9.

NO :

Replace the wheel bearing <front> or rear

wheel hub assembly <rear>. <Refer to

GROUP 26

− Front Axle Hub Assembly

(front), GROUP 27A

− Rear Axle Hub

Assembly (rear-2WD) or GROUP 27B

−

Rear Axle Hub Assembly (rear-4WD)>

Then go to Step 12.

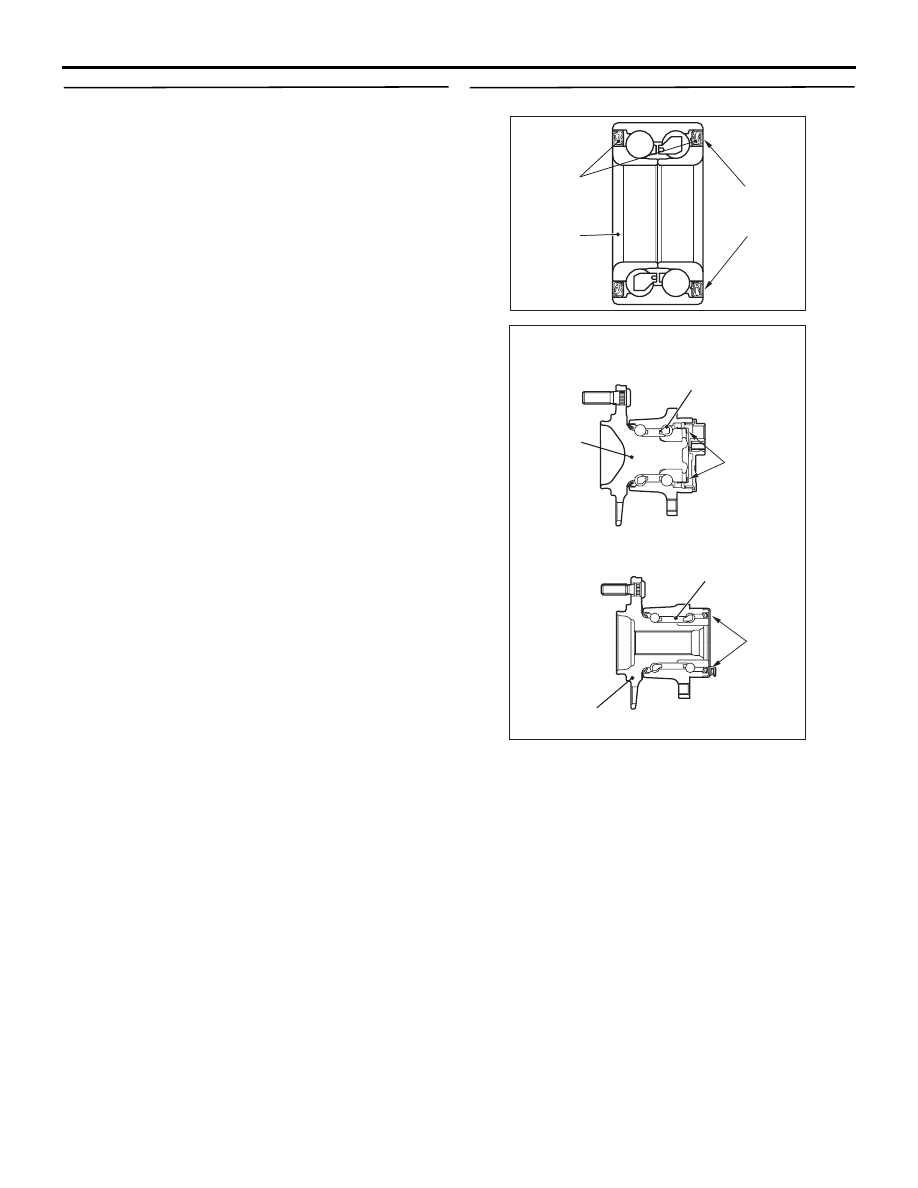

STEP 9. Check of wheel speed detection encoder

AC504925

Oil seal

Magnetic

encoder

AD

Wheel

bearing

<Front>

AC808708

Ball bearing

Rear hub

assembly

Magnetic

encoder

<2WD>

<Rear>

<4WD>

Rear wheel bearing

Rear hub

assembly

Magnetic

encoder

AC

Check the encoder for adhesion of foreign materials

or deformation.

Q: Is the check result normal?

YES :

Go to Step 10.

NO (Adhesion of foreign materials) :

Remove the

foreign materials and clean the encoder so

as not to disturb the magnetization pattern

on it while taking care of the magnet,

magnetic substance, and magnetic

attraction. Then go to Step 12.

NO (Deformation) :

Replace the wheel bearing

<front> or rear wheel hub assembly <rear>.

<Refer to GROUP 26

− Front Axle Hub

Assembly (front), GROUP 27A

− Rear Axle

Hub Assembly (rear-2WD) or GROUP 27B

− Rear Axle Hub Assembly (rear-4WD)>

Then go to Step 12.