Mitsubishi Outlander (2013+). Manual - part 429

MB990326

ON-VEHICLE SERVICE

REAR SUSPENSION

34-4

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011001278

1. Before the wheel alignment measurement, adjust

the rear suspension, wheel, and tyres in good

condition.

2. Park the vehicle on a level surface to measure the

wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread: 3

± 2 mm

Toe-angle (per wheel): 0

° 02’ − 0 ° 12’

If it is out of the standard range, adjust as follows:

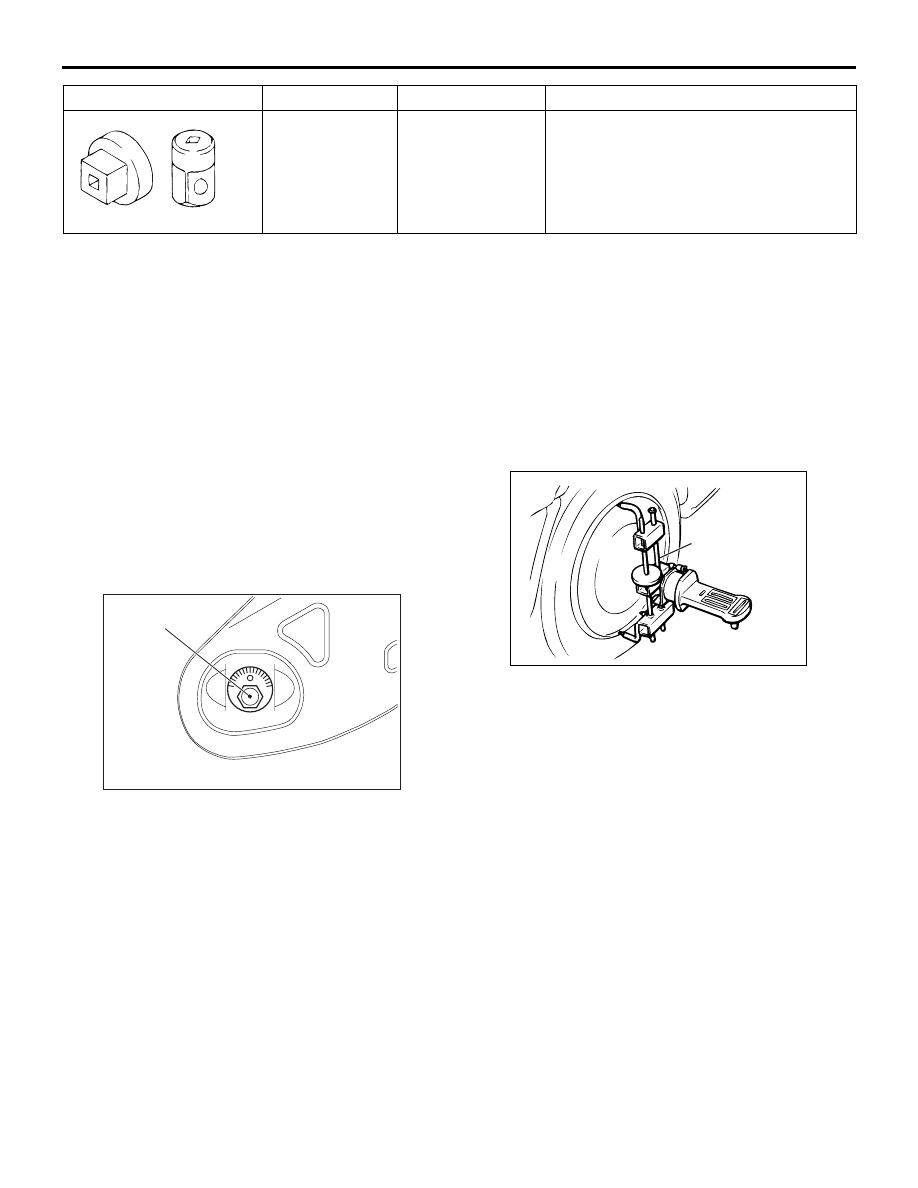

AC506806AB

Toe adjusting bolt

Turn the toe adjusting bolt (the mounting bolt inside

the body on the control link) to adjust.

Left wheels: Clockwise (+) Toe in

Right wheels: Clockwise (

−) Toe in

Toe-in varies approximately 2.6 mm (equivalent to

0

°16' of the toe angle for one side) for each scale

mark.

CAMBER

Standard value:

−0°30' ± 0°45'

NOTE:

.

•

Difference between right and left wheels must be

0

°

30' or less.

•

The camber is pre-adjusted at factory and is not

adjustable.

•

AC305848 AC

Compensator

As for vehicles with aluminium wheel, use a compen-

sator to measure the camber and caster.

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION

M1341019100027

1. Using your fingers, press the dust cover to check

for a crack or damage.

2. If the dust cover has a crack or damage, replace

the stabilizer link.

NOTE: If the dust cover has a crack or damage,

the ball joint could be damaged.

MB990326

Preload socket

Stabilizer link ball joint rotation torque

measurement

Tool

Number

Name

Use