Mitsubishi Outlander (2013+). Manual - part 346

STARTING SYSTEM

ENGINE ELECTRICAL

16-20

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION

M1162001003348

Pre-removal operation

• Air cleaner intake duct and air intake hose removal (Refer

to GROUP 15

− Air cleaner ).

• Battery and battery tray removal (Refer to GROUP 54A −

Battery ).

• Engine room under cover panel removal (Refer to

GROUP 51

− Under cover ).

Post-installation operation

• Engine room under cover panel installation (Refer to

GROUP 51

− Under cover ).

• Battery and battery tray installation (Refer to GROUP 54A

− Battery ).

• Air cleaner intake duct and air intake hose installation

(Refer to GROUP 15

− Air cleaner ).

AC611210

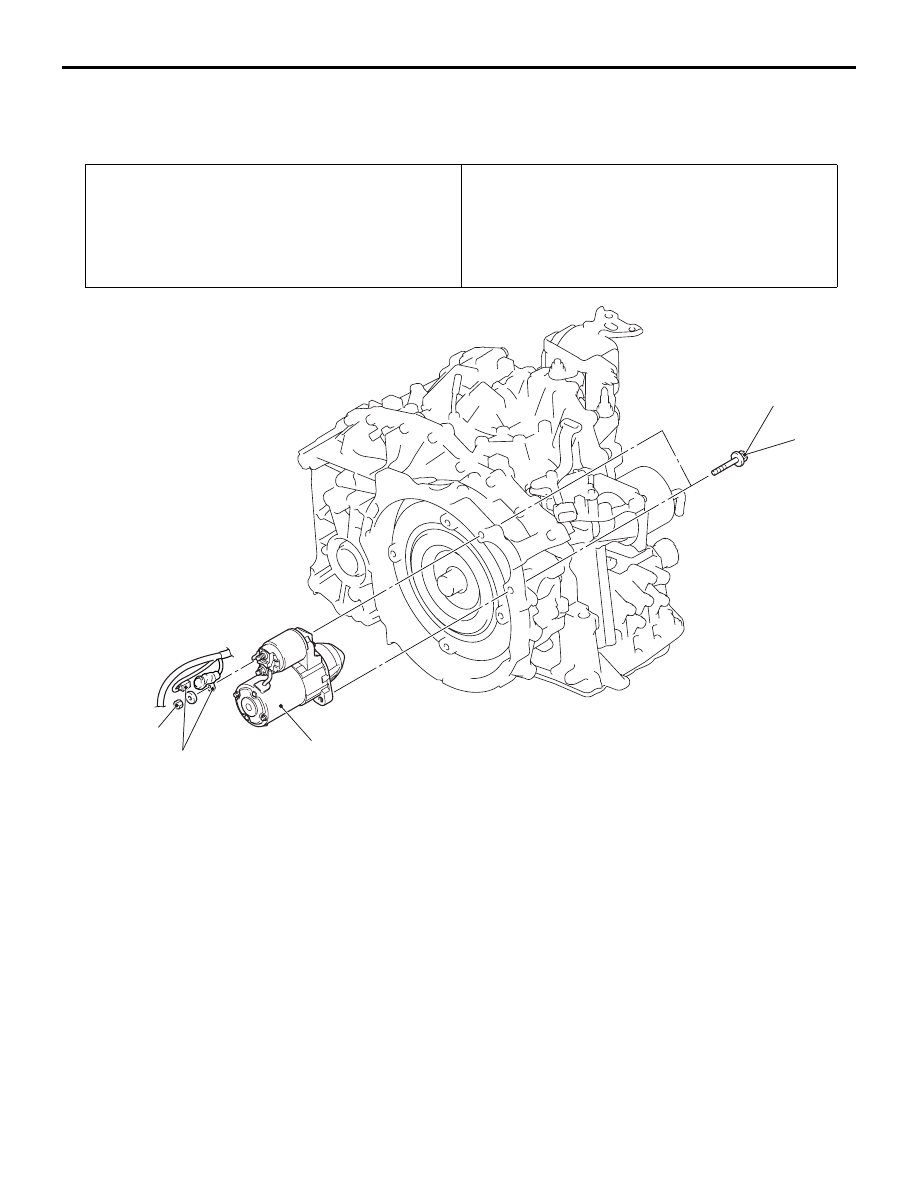

36 ± 9 N·m

11 ± 1 N·m

2

AC

3

1

Removal steps

<<

A

>>

•

Throttle body assembly mounting

bolt (Refer to GROUP 13A

−

Throttle Body Assembly .)

1.

Starter mounting bolt

<<

B

>>

2.

Starter connector and terminal

<<

B

>>

3.

Starter assembly

REMOVAL SERVICE POINTS

<<A>> THROTTLE BODY ASSEMBLY

MOUNTING BOLT REMOVAL

1. Remove the throttle body assembly together with

the water hose from the inlet manifold.

2. Tie the removed throttle body assembly with a

string at a position where it will not interfere with

the operation.

<<B>> STARTER CONNECTOR AND

TERMINAL/STARTER ASSEMBLY

REMOVAL

1. Slide the starter assembly, and remove the starter

connector and terminal.

2. Remove the starter assembly from the lower front

of the engine.