Mitsubishi Outlander (2013+). Manual - part 311

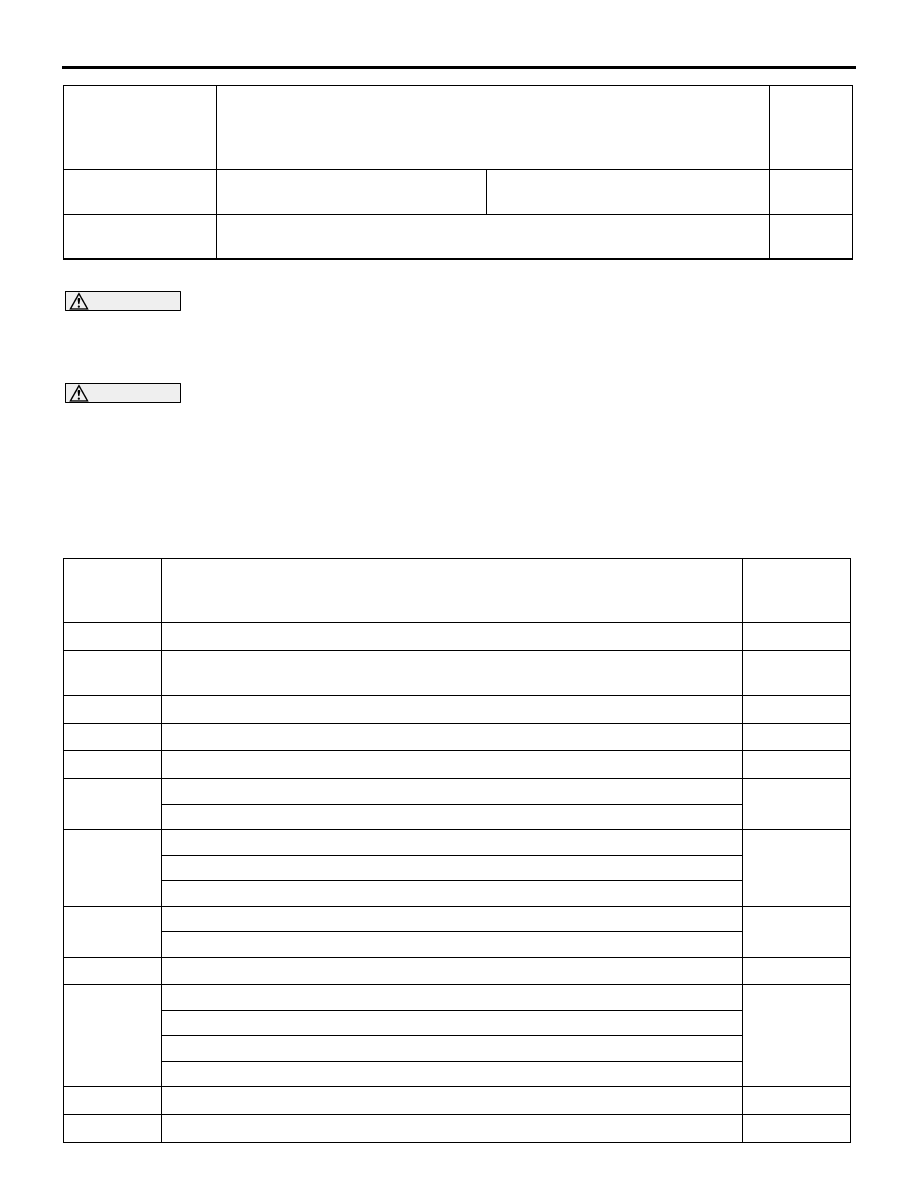

TROUBLESHOOTING

MULTIPOINT FUEL INJECTION (MPI)

13A-125

PROBLEM SYMPTOMS TABLE

WARNING

When touching the throttle valve, surely shut off the driving circuits of the throttle valve. In

the event that the throttle valve is operated, a finger might be injured as the result of being

caught by the throttle valve.

CAUTION

During troubleshooting if the ignition switch is turned to ON with the connectors, etc. disconnected,

some diagnosis code may be saved in other system. After the troubleshooting is completed, always

make sure the diagnosis codes of the entire systems. If it is found that some diagnosis codes have

been outputted, erase them.

NOTE: When the racing (2,000 to 5,000 r/min or more) continues on the vehicle stopped with no load during

the specified time or more, the increase in the engine speed might be limited. This comes from the engine

protection and control functions and is not a malfunction.

Cooling

performance

Overheating

The temperature of engine cooling

water is extremely high.

18

ECO mode

indicator

In running, the ECO mode indicator shows nothing.

24

Item

Trouble Symptom

Inspectio

n

Procedur

e No.

Inspection

Procedure

No.

Inspection Item

Reference

Page

1

The communication between M.U.T.-III and engine-ECU is not possible

2

The engine warning lamp does not illuminate right after the ignition switch is

turned the ON position

3

The engine warning lamp remains illuminating and never goes out

4

Starting impossible (starter not operative)

5

Starting impossible (starter operative but no initial combustion)

6

Starting impossible (initial combustion but no complete combustion)

Improper starting (long time to start)

7

Unstable idling (rough idling, hunting)

Improper idling speed (too high or too low)

Engine stalls during idling (die out)

8

The engine stalls when starting the car (pass out)

The engine stalls when decelerating

9

Engine does not revolve up

10

Hesitation, sag

Poor acceleration

Stumble

Surge

11

The feeling of impact or vibration when accelerating

12

The feeling of impact or vibration when decelerating