Mitsubishi Outlander (2013+). Manual - part 266

EXHAUST MANIFOLD

ENGINE OVERHAUL

11B-18

REMOVAL SERVICE POINTS

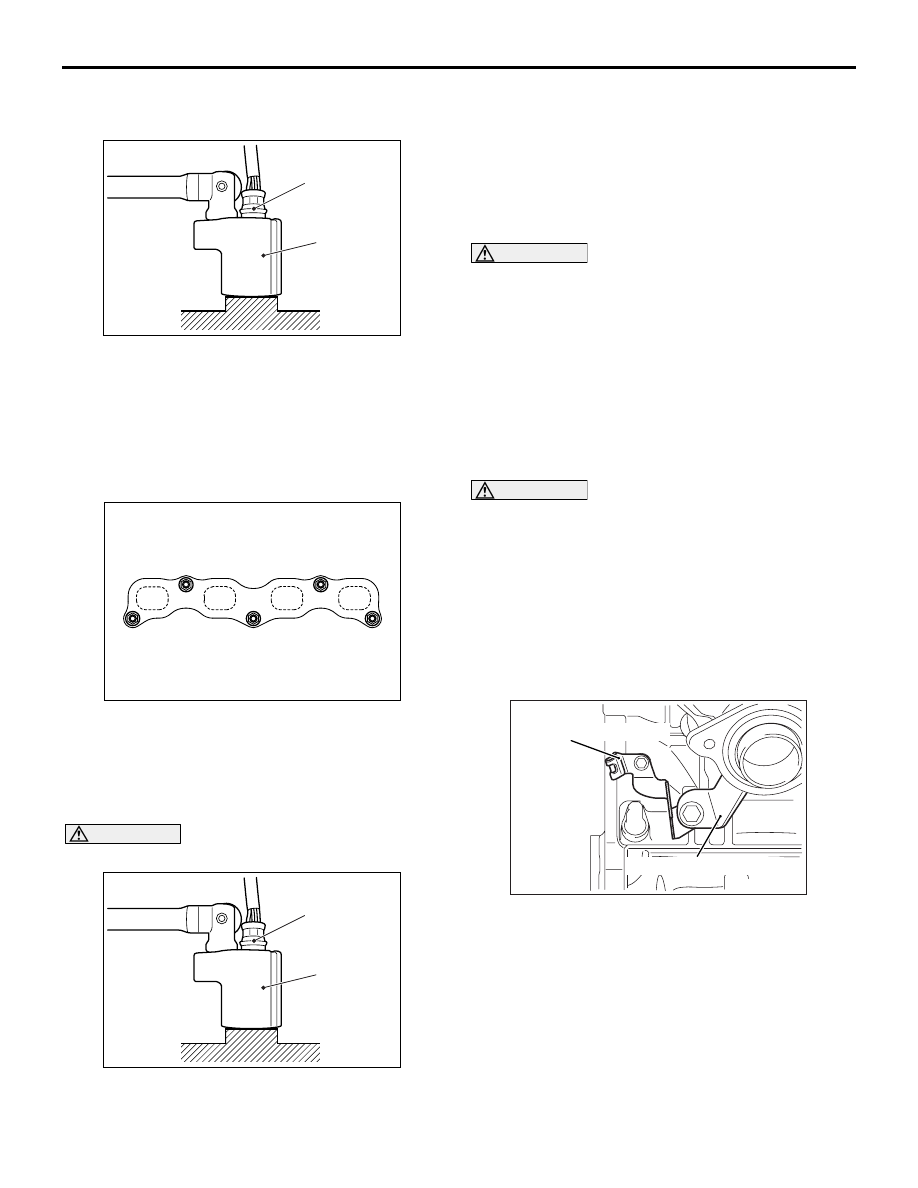

<<A>> OXYGEN SENSOR REMOVAL

AC301966

AB

MB991953

Oxygen sensor

Remove the connection and clamp of oxygen sensor

connector, and then use special tool oxygen sensor

wrench (MB991953) to remove the oxygen sensor.

INSTALLATION SERVICE POINTS

>>A<< EXHAUST MANIFOLD INSTALLA-

TION

AKB00880

1

2

AB

3

4

5

1. Tighten the exhaust manifold nut to the specified

torque of 49

± 5 N⋅m in the order shown in the

illustration.

>>B<< OXYGEN SENSOR INSTALLATION

CAUTION

•

AC301966

AB

MB991953

Oxygen sensor

Do not use a sensor that has fallen down.

Tighten the oxygen sensor to the specified torque by

using special tool oxygen sensor wrench

(MB991953).

Tightening torque: 44

± 5 N⋅m

>>C<< CRANK ANGLE SENSOR / O-RING

INSTALLATION

CAUTION

• Do not apply a force such as torsion or twist

to the O-ring during assembly of the sensor.

• Assemble the sensor, taking care not to give a

shock to it.

• Do not use a sensor that has fallen down.

Tighten the crank angle sensor to the specified

torque of 11

± 1 N⋅m.

>>D<< EXHAUST MANIFOLD BRACKET

INSTALLATION

CAUTION

The exhaust manifold gasket, washers and nuts

must not be reused.

1. After temporarily tightening the exhaust manifold

bracket with the installation bolts, check the

exhaust manifold fastens securely to the cylinder

block.

2. Tighten the cylinder block side bolt to the

specified tightening torque.

Tightening torque: 41

± 10 N⋅m

AKC00009

Crank angle sensor cover

Exhaust manifold bracket

AB

3. Tighten the exhaust manifold side bolt to the

specified tightening torque.

Tightening torque: 56

± 8 N⋅m