Mitsubishi Outlander (2013+). Manual - part 132

SENSOR

MULTIPOINT FUEL INJECTION (MPI)

13A-12

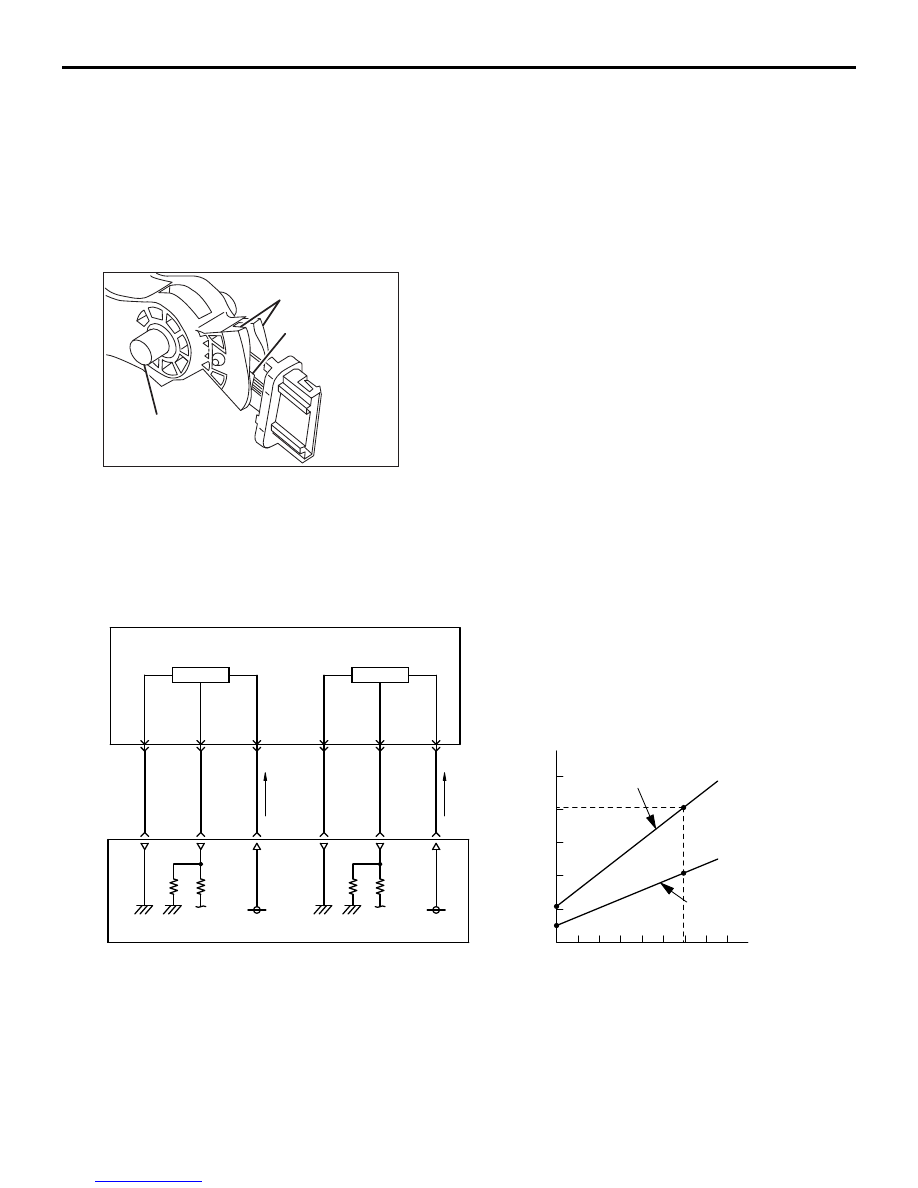

Accelerator pedal position sensor is integrated with

accelerator pedal, and detects accelerator opening

angle. Engine-ECU uses the output voltage of this

sensor to control appropriate throttle valve opening

angle and fuel injection volume. This accelerator

pedal position sensor uses Hall IC and is a non-con-

tact type.

STRUCTURE AND SYSTEM

Accelerator pedal position sensor is composed of a

permanent magnet fixed on the magnet carrier of the

pedal shaft, Hall IC outputs voltage according to

magnetic flux density and a stator that efficiently

introduces magnetic flux from the permanent magnet

to Hall IC.

Magnetic flux density at Hall IC is proportional to the

output voltage.

The accelerator pedal position sensor has 2 output

systems

− accelerator pedal position sensor (main)

and accelerator pedal position sensor (sub), and the

output voltage is output to engine-ECU. According to

depression of the accelerator pedal, output voltage

of the accelerator pedal position sensor (main) and

accelerator pedal position sensor (sub) changes.

This allows engine-ECU to detect the actual acceler-

ator pedal depression amount. Engine-ECU uses

accelerator pedal position sensor (main) output volt-

age for appropriate throttle valve opening angle con-

trol and fuel injection volume control. Also,

engine-ECU compares output voltage of the acceler-

ator pedal position sensor (main) and accelerator

pedal position sensor (sub) to check for abnormality

in sensor. The relationship between accelerator

opening angle and output voltage of the accelerator

pedal position sensor (main) and accelerator pedal

position sensor (sub) is as shown in the figure below.

AK602570AB

Magnet

Pedal shaft

Hall IC

AK602211

5V

5V

5

4

3

2

1

0

AD

Accelerator pedal position sensor

Accelerator pedal

position sensor (main)

Accelerator pedal

position sensor (main)

Accelerator

pedal stroke

Accelerator pedal

position sensor (sub)

Accelerator pedal

position sensor (sub)

Hall IC

Hall IC

Full throttle

point

Output voltage (V)

Engine-ECU

manuals search engine