Mitsubishi Outlander (2013+). Manual - part 16

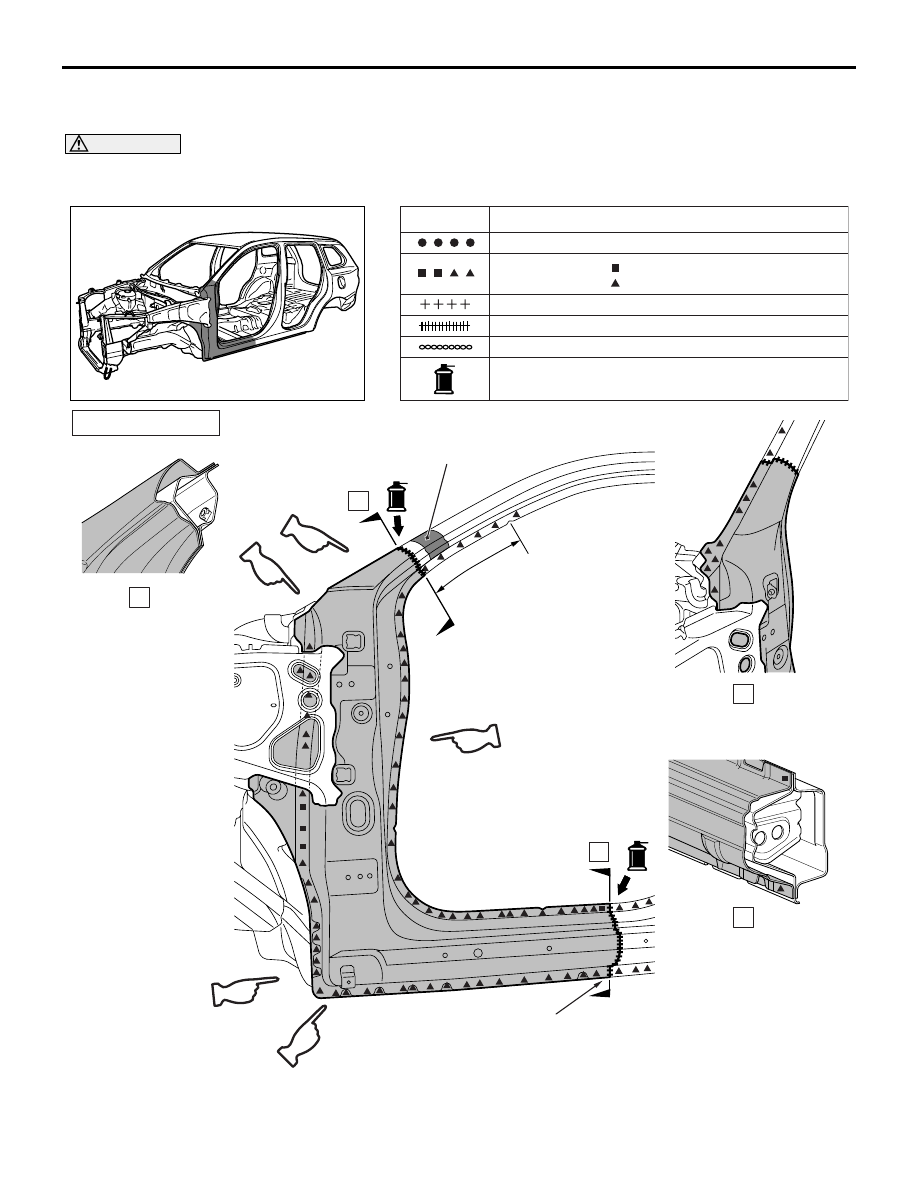

FRONT PILLAR

WELDED PANEL REPLACEMENT

3-9

FRONT PILLAR

M4030005002113

CAUTION

When repairing the area using sound dampening foam material do not use firing tools since the

sound dampening foam material may burn.

ABC99914

AB

Symbol

Operation description

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

ABB00889

A

B

C

270 mm

C

AB

B

E

D

A

G

F

Sound dampening

foam material

REPAIR WELDS

The same position as the

new front outer pillar parts