Mitsubishi Outlander (2013+). Manual - part 3

MAINTENANCE, SERVICEABILITY

BODY CONSTRUCTION

1-6

MAINTENANCE, SERVICEABILITY

M4010003001156

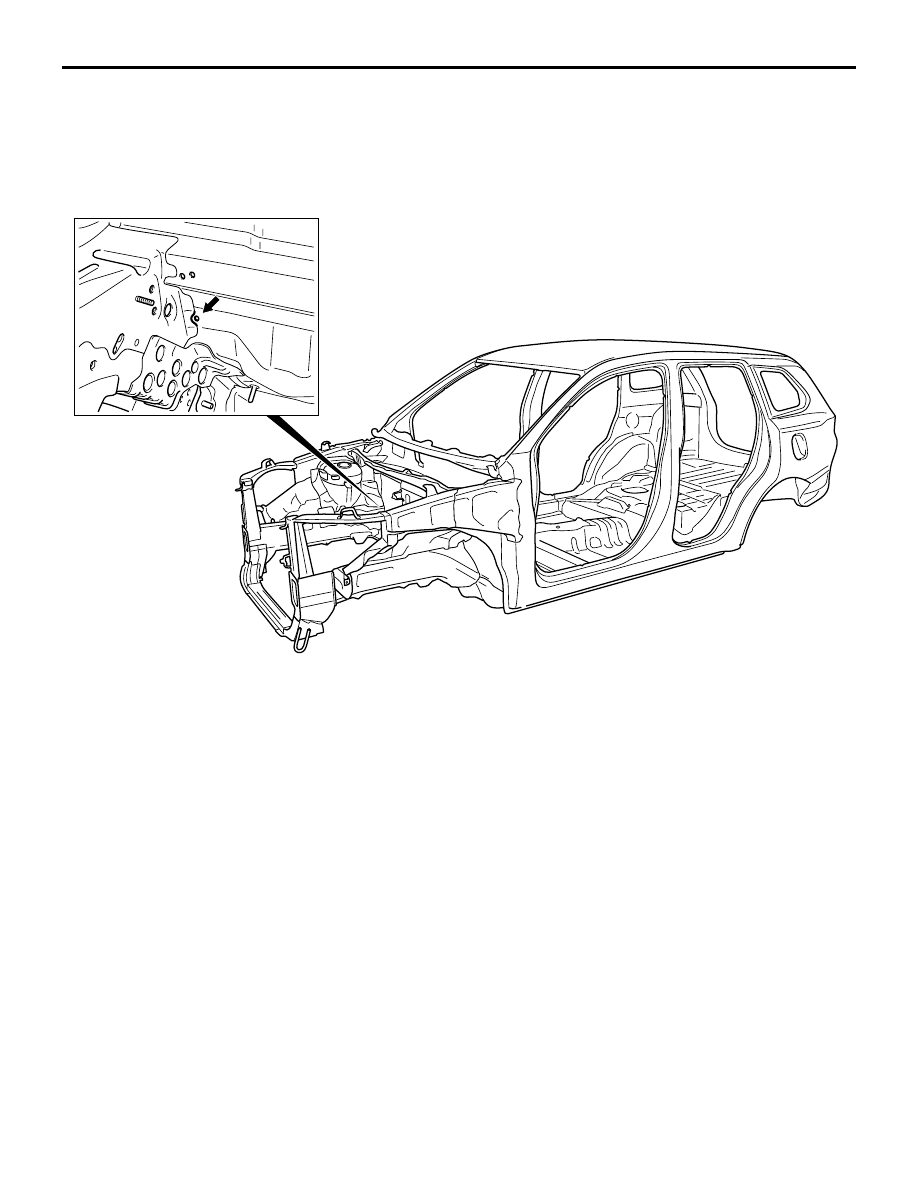

FENDER SHIELD

To facilitate the panel replacement, the dash panel

and the front sidemember brace upper have a pro-

jection and recess for alignment.

SIDE STRUCTURE

A panel positioning notch has been added on the

door opening to improve assembling workability

when replacing the panel.

ABB00904AB