Mitsubishi Outlander (2003+). Manual - part 540

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION

55A-55

NOTE: The low-pressure service valve should be

connected to the suction hose.

8. Start the engine.

9. Operate the air conditioner and set at the lowest

temperature (MAX. COOL).

10.Fix the engine speed at 1,500 r/min.

11.Tighten the handle of the adaptor valve (valve

open), and replenish refrigerant while checking

the quantity through the sight glass.

12.After replenishing is completed, turn the handle of

the adaptor valve all the way back (valve close),

and remove the quick joint.

NOTE: When there is remainder of refrigerant in

the service can, keep it for next use with the

charge value and the valve of the adaptor valve

being closed.

DISCHARGING SYSTEM

M1552013000086

Use the refrigerant recovery unit to discharge

refrigerant gas front the system.

NOTE: Refer to the Refrigerant Recovery and

Recycling Unit instruction Manual for operation of the

unit.

REFILLING OF OIL IN THE A/C SYSTEM

M1552020000055

Too little oil will provide inadequate compressor

lubrication and cause a compressor failure. Too

much oil will increase discharge air temperature.

When a compressor is installed at the factory, it

contains 120 mL <MSC90CA> or 140mL

<MSC105CA> of compressor oil. While the A/C

system is in operation, the oil is carried through the

entire system by the refrigerant. Some of this oil will

be trapped and retained in various parts of the

system.

When the following system components are

changed, it is necessary to add oil to the system to

replace the oil being removed with the component.

Compressor oil: SUN PAG 56

Quantity

Evaporator: 60 mL

Condenser: 15 mL

Flexible suction hose: 10 mL

Receiver: 10 mL

PERFORMANCE TEST

M1552001400333

1. The vehicles to be tested should be in a place that

is not in direct sunlight.

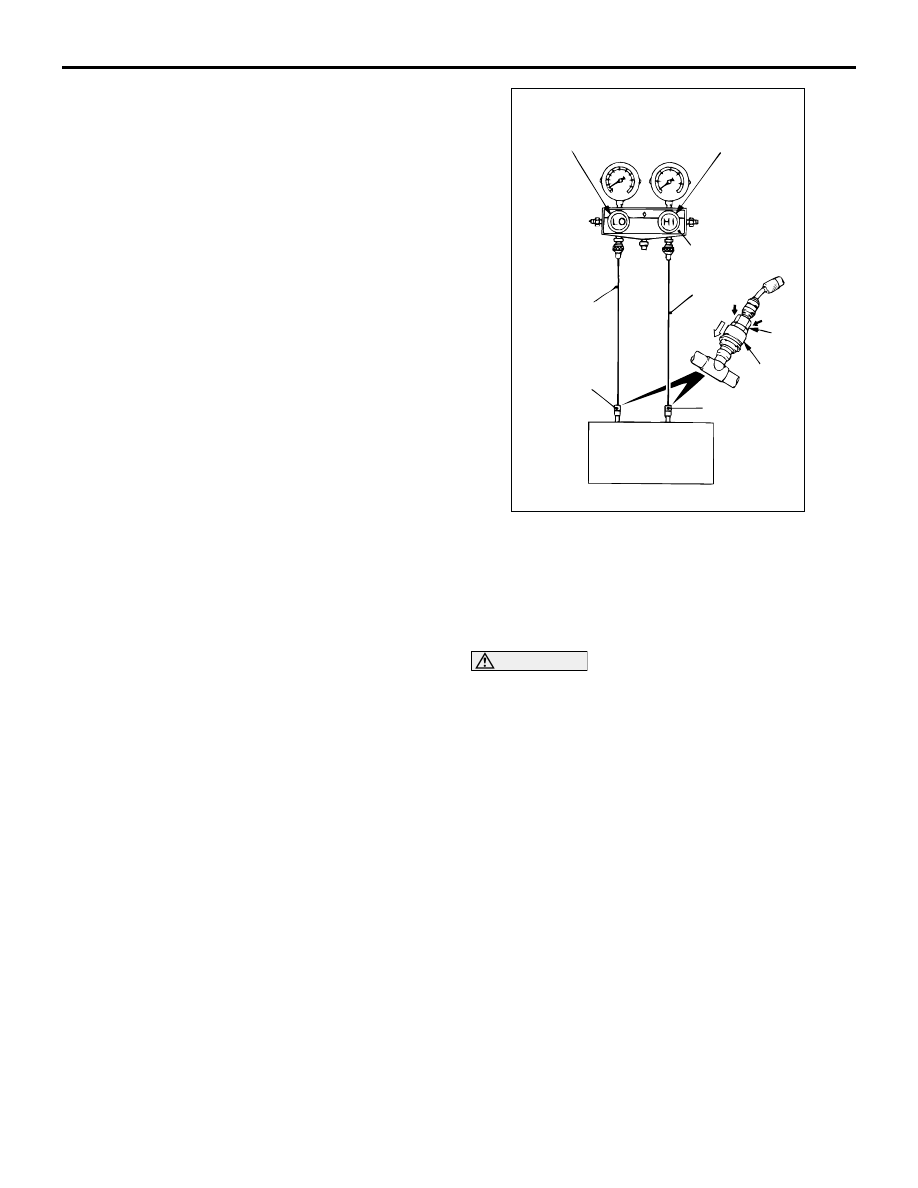

2. Close the high and low-pressure valve of the

gauge manifold.

3. Connect the charging hose (blue) to the

low-pressure valve and connect the charging

hose (red) to the high-pressure valve of the gauge

manifold.

CAUTION

•

To connect the quick joint, press section A

firmly against the service valve until a click is

heard.

•

When connecting, run your hand along the

hose while pressing to ensure that there are

no bends in the hose.

4. Install the quick joint (for low-pressure) to the

charging hose (blue), and connect the quick joint

(for high-pressure) to the charging hose (red).

NOTE: The high-pressure service valve is on the

A/C pipe and the low-pressure service valve is on

the suction hose.

5. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick

joint (for high-pressure) to the high-pressure

service valve.

6. Start the engine.

7. Set the A/C controls as follows:

•

A/C switch: A/C

−

ON position

•

Mode selection: FACE position

•

Temperature control: MAXIMUM COOLING

position

•

Air selection: RECIRCULATION position

AC001388

Low-pressure

valve

High-pressure

valve

Gauge manifold

Charging

hose (red)

A

Sleeve

Charging

hose (blue)

Adaptor valve

(for low-

pressure)

Low-

pressure

service

valve

High-

pressure

service

valve

AB

Adaptor valve

(for high-

pressure)