Mitsubishi Outlander (2003+). Manual - part 302

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING

37A-31

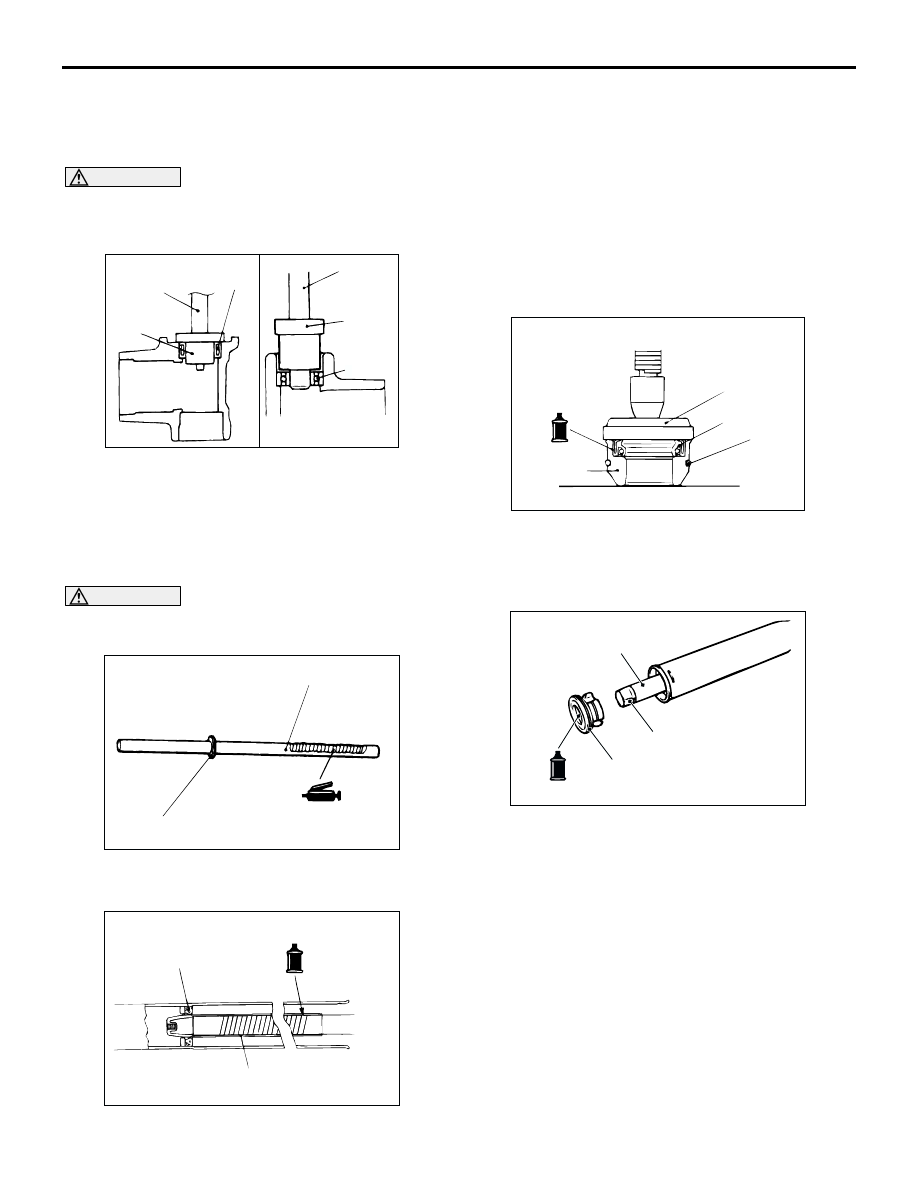

>>B<< NEEDLE BEARING/LOWER BEARING

INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing,

bearing and oil seal press fitting surface.

CAUTION

Press-fit straight. The valve housing is

aluminium, and may become deformed if

press-fit on an angle.

2. Press fit needle bearing with the following special

tools.

•

MB990938: Bar (Snap-in type)

•

MB991202: Oil Seal and Bearing Installer

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

1. Apply a coating of repair kit grease to the rack

teeth face.

2. Cover rack serrations with special tool rack

installer (MB991213).

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to

prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to the outer

surface of the oil seal. Using the special tool

installer adapter (MB990927), press in the oil seal

until it is flush with the bushing end face.

2. Apply ATF DEXRON III or DEXRON II to the oil

seal inner surface and the O-ring.

3. Wrap the rack end with plastic tape, and push the

rack bushing onto the rack.

ACX01153

Needle bearing

MB990938

MB991202

MB991202

Lower

bearing

AE

MB990938

ACX01154 AB

Seal ring and O-ring

Vent hole

ACX01155

MB991213

AB

Oil seal

ACX01156 AE

Oil seal

O-ring

MB990927

Rack

bushing

AC100261AB

Rack

Vinyl tape

Rack bushing