Mitsubishi Outlander (2003+). Manual - part 241

TROUBLESHOOTING

WHEEL AND TYRE

31-3

TROUBLESHOOTING

DIAGNOSIS

M1311000700363

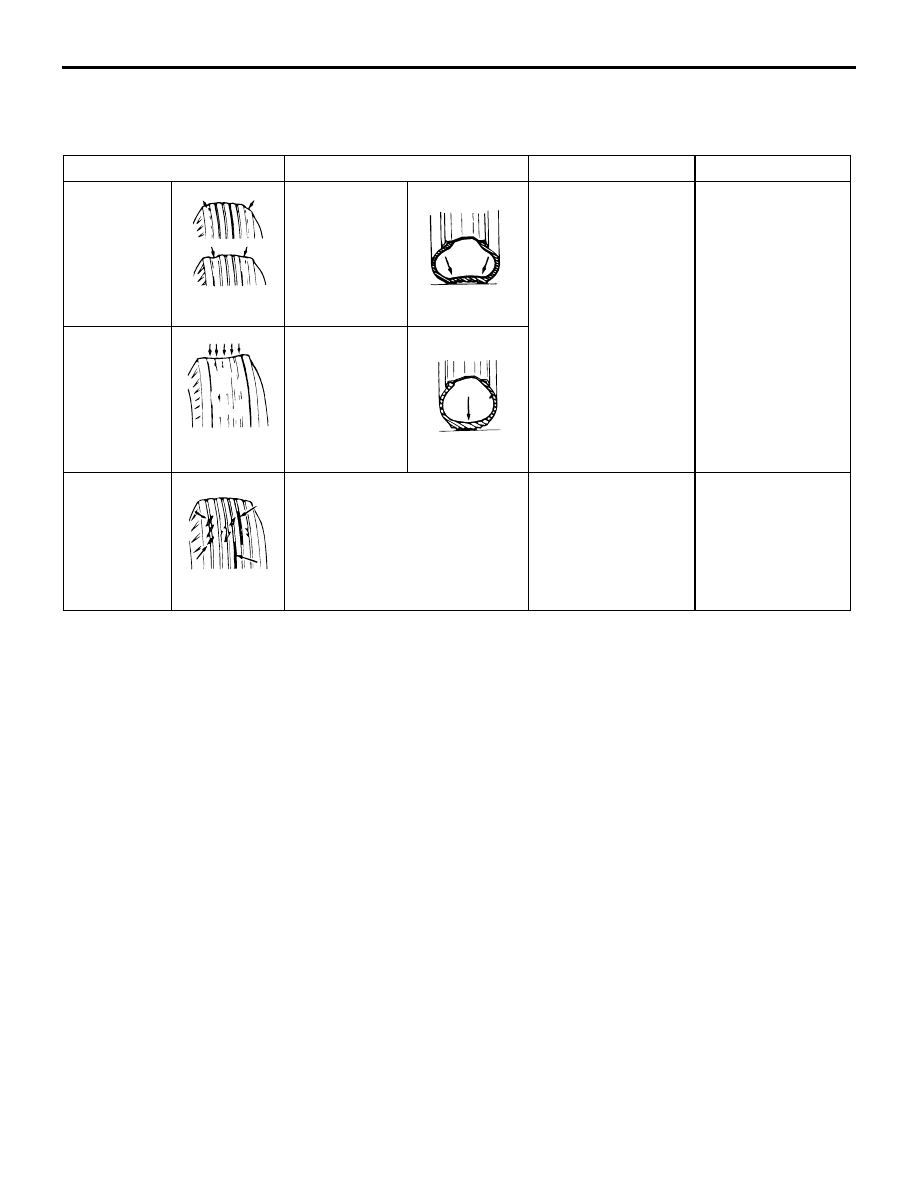

Symptom

Probable cause

Remedy

Reference page

Rapid wear

at shoulders

Under-inflation

or lack of

rotation

Adjust the tyre

pressure.

For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

Rapid wear

at centre

Over-inflation

or lack of

rotation

Cracked

treads

Under-inflation

Adjust the tyre

pressure.

For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

ACX00923AB

ACX00924 AB

ACX00925AB

ACX00926AB

ACX00927AB