Mitsubishi Outlander (2003+). Manual - part 158

SPECIAL TOOLS

MANUAL TRANSMISSION (FF)

22A-3

SPECIAL TOOLS

M1221000600672

Tool

Number

Name

Use

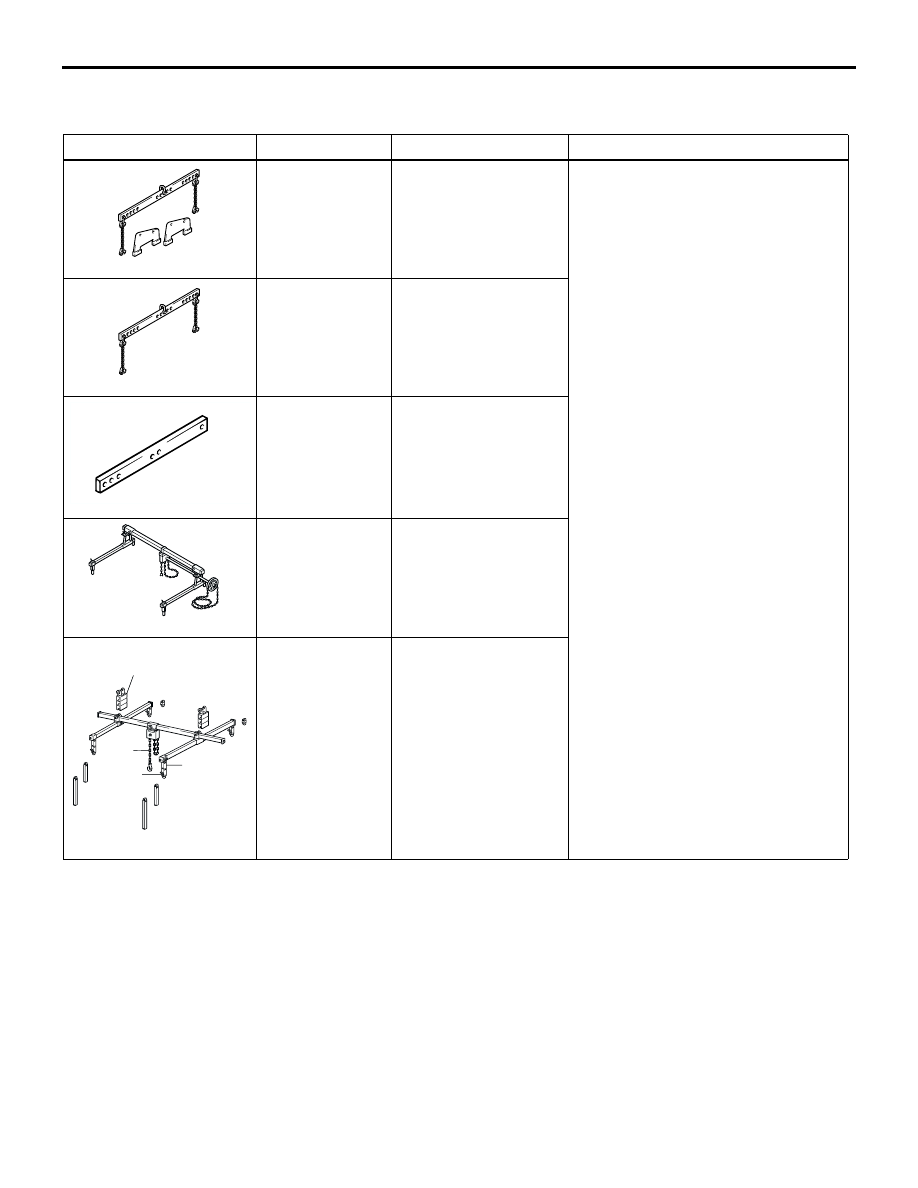

MB991453

Engine hanger

assembly

When the engine hanger is used:

Supporting the engine assembly

during removal and installation of the

transmission assembly

NOTE: Special tool MB991454 is a

part of engine hanger attachment set

MB991453.

MB991454

Engine hanger

balancer

MB991527

Engine hanger

MB991895

Engine hanger

MB991928

A: MB991929

B: MB991930

C: MB991931

D: MB991932

E: MB991933

F: MB991934

Engine hanger

A: Joint (50)

×

2

B: Joint (90)

×

2

C: Joint (140)

×

2

D: Foot (standard)

×

4

E: Foot (short)

×

2

F: Chain and hook

assembly

B991453

B991454

B991527

MB991895

B991928

A

B

C

D

E

F

Slide bracket (HI)