Mitsubishi Outlander (2003+). Manual - part 138

CHARGING SYSTEM

ENGINE ELECTRICAL

16-17

DISASSEMBLY SERVICE POINTS

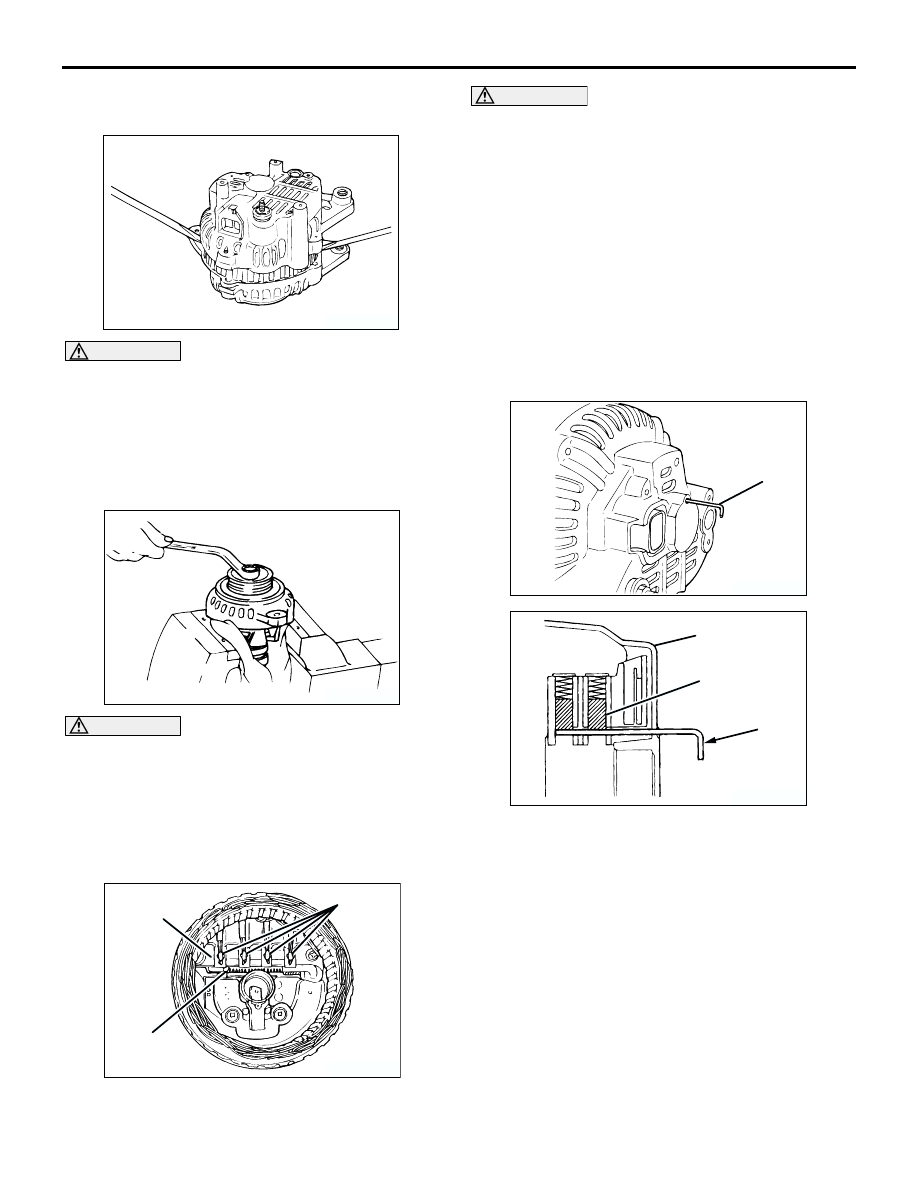

<<A>>FRONT BRACKET ASSEMBLY REMOVAL

CAUTION

Do not insert the screwdriver blades too deep.

Doing so could damage the stator coil.

Insert the blades of screwdrivers between the front

bracket assembly and stator core, and pry and

separate them with the screwdrivers.

<<B>>ALTERNATOR PULLEY REMOVAL

CAUTION

Perform operation carefully not to damage the

rotor.

Clamp the rotor in a vise with the pulley facing up to

remove the pulley.

<<C>>STATOR / REGULATOR ASSEMBLY

REMOVAL

CAUTION

•

Use a 180

−

250 W soldering iron, and finish

unsoldering within four seconds. Diodes will

be damaged by heat if unsoldering time is too

long.

•

Avoid applying undue force to the diode

leads.

1. Unsolder the stator leads from the main diode of

the rectifier assembly when the stator is removed.

2. When removing the rectifier assembly from the

regulator assembly, undo the soldered points on

the rectifier assembly.

REASSEMBLY SERVICE POINTS

>>A<<REGULATOR ASSEMBLY INSTALLATION

After installing the regulator assembly, insert a piece

of wire through the hole in the rear bracket while

pressing the brush to keep the brush against

movement.

NOTE: Holding the brush with the wire facilities

installation of the rotor.

AK202718

AK202714

AK202778

Solder

Solder

Rectifier

assembly

AB

AK202779

Wire

AB

AK202830

Rear bracket

Brush

Wire

AB