Mitsubishi Montero Sport (2004+). Manual - part 719

ON-VEHICLE SERVICE

TSB Revision

AUTOMATIC TRANSMISSION

23A-441

SHIFT LOCK MECHANISM CHECK

M1232001000343

1. Perform the following inspections.

2. When any of the above shift lock inspection procedures fail,

adjust the shift lock cable as follows:

(1) Remove the floor console. (Refer to GROUP 52A

− Floor

Console

(2) Shift the selector lever to the "P" position.

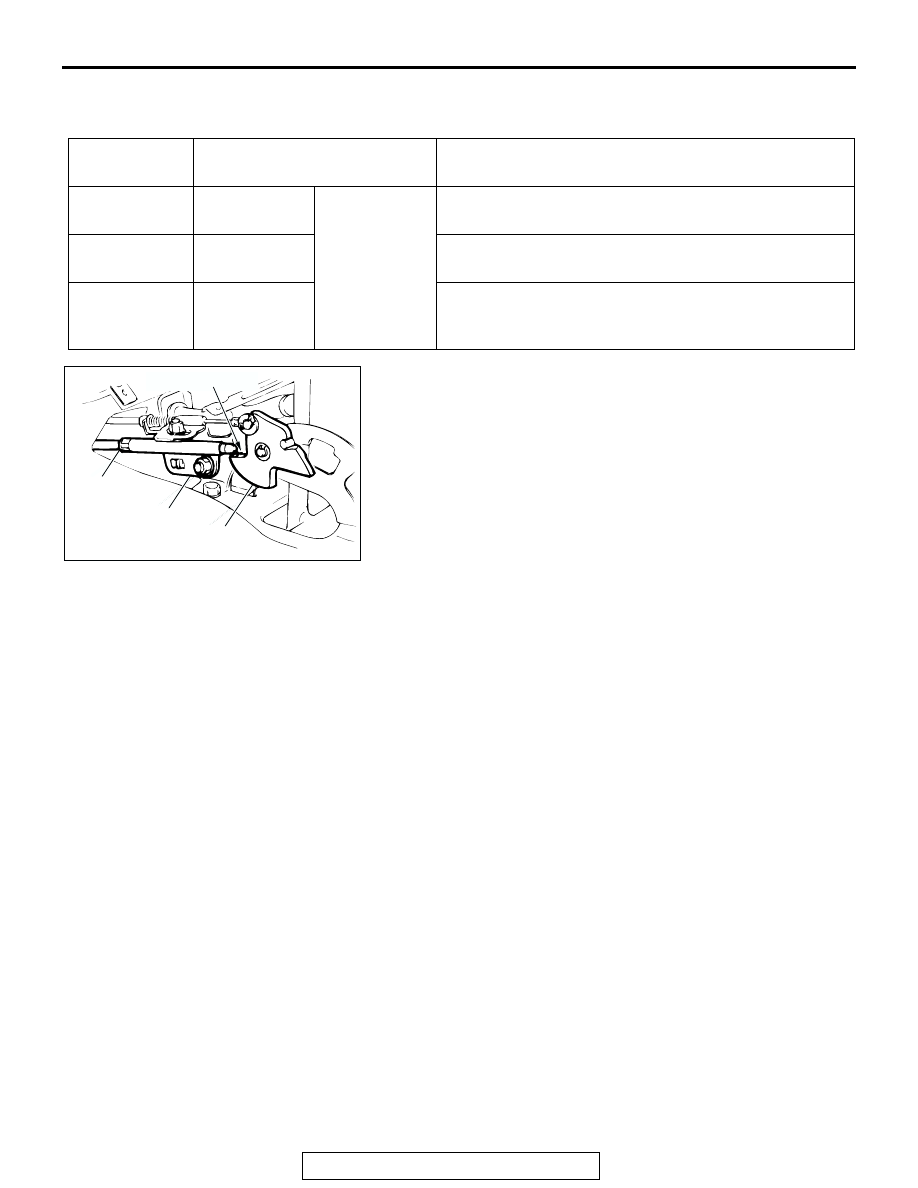

(3) Loosen the lock nut on the shift lock cable.

(4) Adjust the cable so that the end of the shift lock cable is

above the red line on the lock cam and tighten the

locknut.

Tightening torque: 12 N

⋅m (106 in-lb)

(5) After adjusting, retest the shift lock cable operation.

Replace the shift lock cable if it does not operate

properly. (Refer to

(6) Install the floor console.

AUTOMATIC TRANSMISSION CONTROL

COMPONENT CHECK

CRANKSHAFT POSITION SENSOR CHECK

M1231102700145

Refer to GROUP 13A, Diagnosis

− Check Procedure with

Oscilloscope

TP SENSOR CHECK

M1231102500152

Refer to GROUP 13A, On-vehicle Service

− Throttle Position

Sensor Check

INSPECTION

PROCEDURE

CHECK CONTENTS

CHECK ITEM (NORMAL CONDITION)

1

Brake pedal:

Not depressed

Ignition key

position: "ACC"

When the selector lever push button is depressed, the

selector lever can not be shifted out of the "P" position.

2

Brake pedal:

Depressed

When the selector lever push button is depressed, the

selector lever can be shifted smoothly to other positions.

3

Brake pedal:

Not depressed

When the selector lever push button is depressed, the

selector lever can be shifted smoothly from the "R"

position to the "P position.

AC004518

JAM NUT

LOCK CAM

SHIFT LOCK

CABLE

AC

MARKING (RED)