Mitsubishi Montero Sport (2004+). Manual - part 600

ON-VEHICLE SERVICE

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55-27

ON-VEHICLE SERVICE

REFRIGERANT LEVEL TEST

M1552008400271

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

A/C COMPRESSOR CLUTCH TEST

M1552019900076

1. Disconnect the A/C compressor clutch connector to the A/C

compressor clutch.

2. Connect positive battery voltage directly to the connector for

the A/C compressor clutch.

3. If the A/C compressor clutch is normal, there will be a "click."

If the pulley and armature do not make contact ("click"),

there is a malfunction.

RECEIVER DRIER TEST

M1552008600220

Turn the A/C on. Check the temperature by touching the

receiver drier outlet and inlet pipes. If there is a difference in the

temperatures of the two pipes, the receiver assembly is

restricted. Replace the receiver assembly.

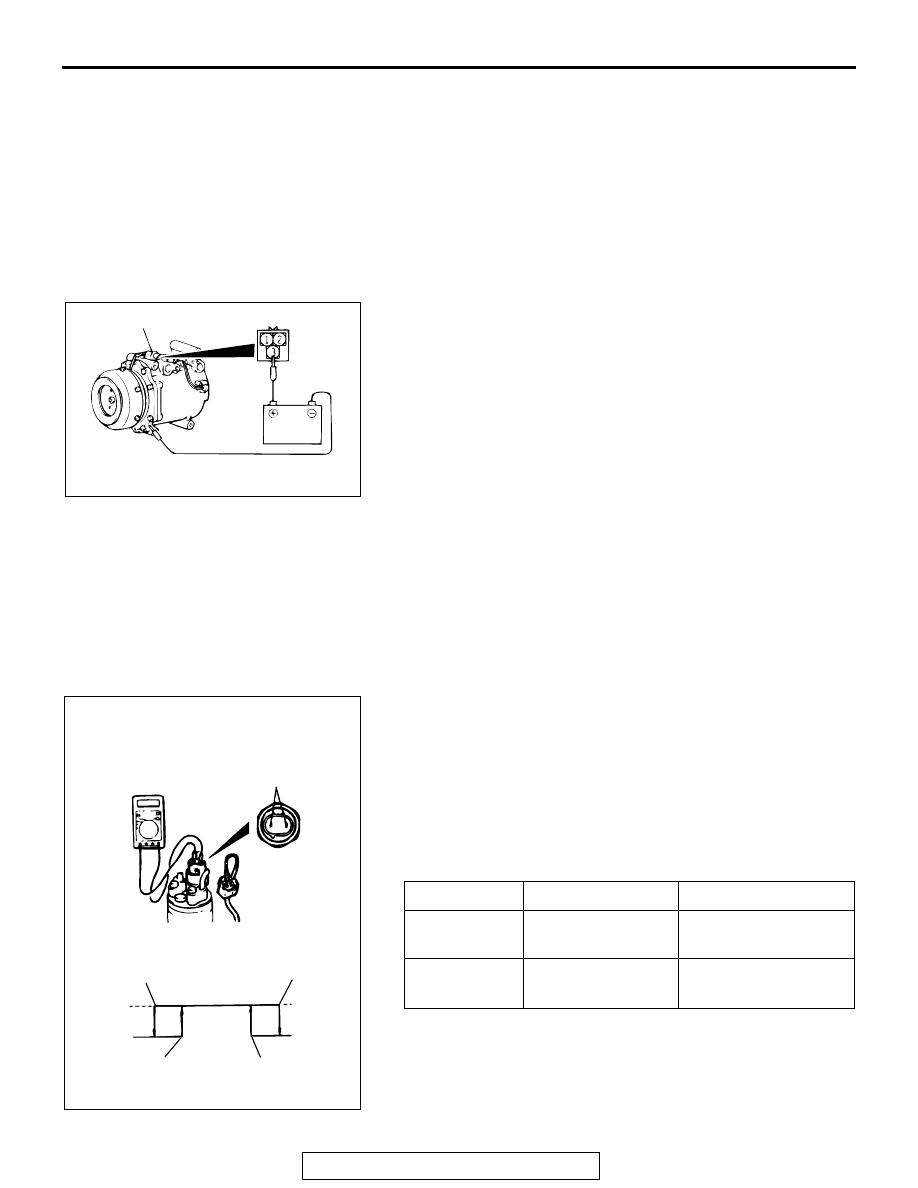

DUAL PRESSURE SWITCH CHECK

M1552010400364

1. Remove the dual pressure switch connector and connect

the high/low pressure side terminals located on the harness

side as shown in the illustration.

2. Install a gauge manifold to the high-pressure side service

valve of the refrigerant line. (Refer to

3. When the high/low pressure sides of the dual pressure

switch are at operation pressure (ON) and there is continuity

between the respective terminals, then the condition is

normal. If there is no continuity, replace the switch.

AC002842

A/C COMPRESSOR CLUTCH

CONNECTOR

AC

ITEM

FROM OFF TO ON FROM ON TO OFF

Low-pressure

side kPa (psi)

221

± 27 (32.1 ±

3.9)

196

± 20 (28.4 ± 2.9)

High-pressure

side kPa (psi)

2,354

± 200 (341.4

± 29)

2,942

± 200 (426.7 ±

29)

A003021

HIGH/LOW

PRESSURE SIDE

LOW-PRESSURE

SIDE

HIGH-PRESSURE

SIDE

ON

OFF

ON

OFF

AC

196 ± 20

(28.4 ± 2.9)

221 ± 27

(32.1 ± 3.9)

kPa (psi)

2942 ± 200

(426.7 ± 29)

2354 ± 200

(341.4 ± 29)