Mitsubishi Montero Sport (2004+). Manual - part 367

ON-VEHICLE SERVICE

TSB Revision

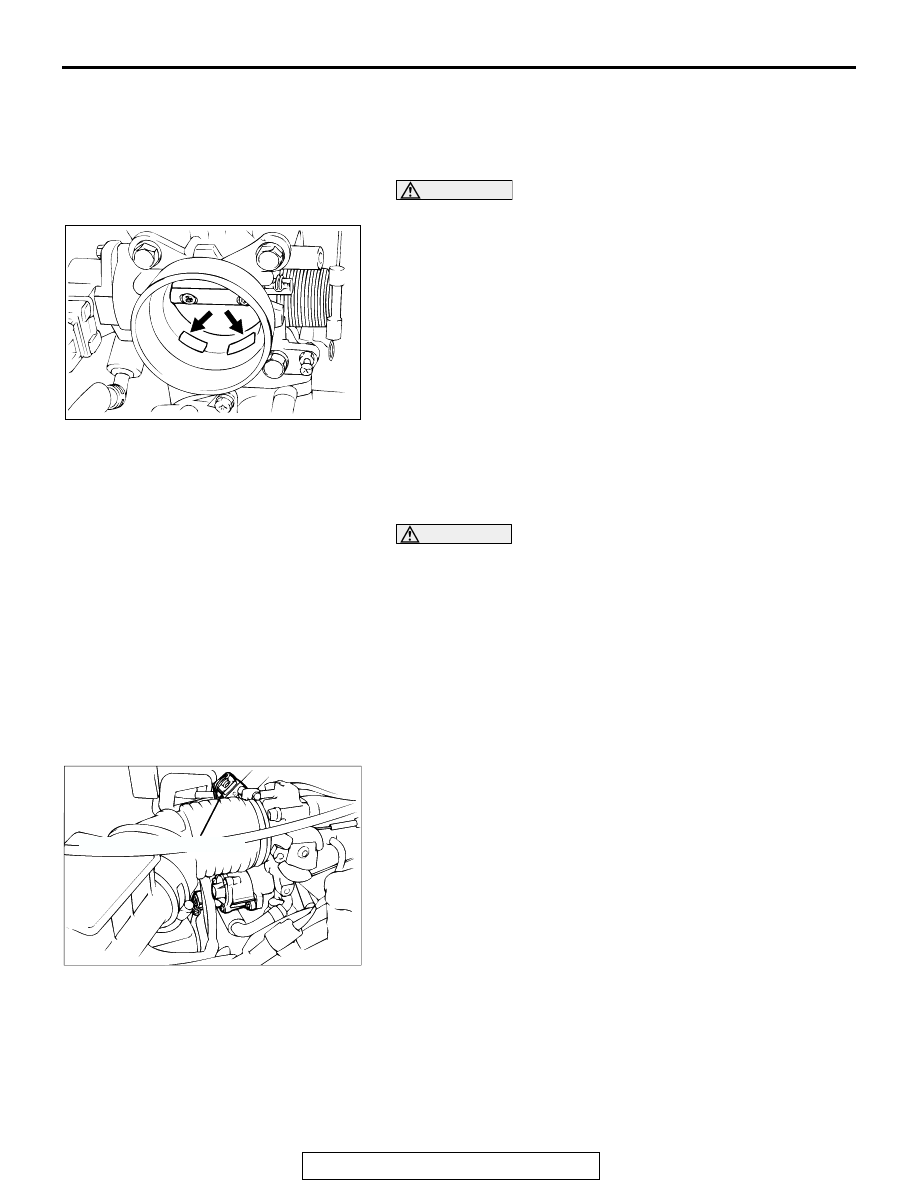

MULTIPORT FUEL INJECTION (MFI)

13A-881

THROTTLE BODY CLEANING

M1131001000473

1. Start the engine and warm it up until the coolant is heated to

80

°C (176°F) or higher. Stop the engine.

2. Remove the air intake hose from the throttle body.

CAUTION

Do not allow cleaning solvent to enter the bypass passage.

3. Plug the bypass passage inlet (arrow) of the throttle body.

4. Spray cleaning solvent into the valve through the throttle

body intake port and leave it for approximately five minutes.

5. Start the engine, rev it several times and then idle it for about

one minute. If the idling speed becomes unstable (or if the

engine stalls) due to the bypass passage being plugged,

slightly open the throttle valve to keep the engine running.

6. If the throttle valve deposits are not removed, repeat steps 4

and 5.

7. Unplug the bypass passage inlet.

8. Attach the air intake hose.

9. Use scan tool MB991958 to erase any diagnostic trouble

code.

10.Adjust the basic idle speed. (Refer to

.)

WARNING

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

NOTE: If the engine hunts while idling after adjustment of

the basic idle speed, disconnect the negative cable from the

battery for 10 seconds or more, and then reconnect it and

run the engine at idle for about 10 minutes after the engine

is warmed up.

THROTTLE POSITION SENSOR ADJUSTMENT

M1131001100555

Required Special Tools:

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I

• MB991827: USB Cable

• MB991911: Main Harness B

• MB991348: Test Harness Set

AK303656AB

AK000332AC

THROTTLE POSITION SENSOR