Mitsubishi Montero Sport (2004+). Manual - part 260

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-453

.

CIRCUIT OPERATION

• The crankshaft position sensor power is supplied

from the MFI relay (terminal No. 1), and the

ground is provided on the vehicle body.

• A 5-volt voltage is applied on the crankshaft posi-

tion sensor output terminal (terminal No. 2) from

the PCM (terminal No. 45). The crankshaft posi-

tion sensor generates a pulse signal when the

output terminal is opened and grounded.

.

TECHNICAL DESCRIPTION

• The crankshaft position sensor detects the crank

angle (position) of each cylinder, and converts

that data to pulse signals, which are then input to

the PCM.

• When the engine is running, the crankshaft posi-

tion sensor outputs a pulse signal.

• The PCM checks whether pulse signal is input

while the engine is cranking.

.

DESCRIPTIONS OF MONITOR METHODS

• Crankshaft position sensor signal does not

change.

• Crankshaft position sensor signal is not normal

pattern.

.

MONITOR EXECUTION

Continuous

.

MONITOR EXECUTION CONDITIONS (Other

monitor and Sensor)

Other Monitor (There is no temporary DTC stored

in memory for the item monitored below)

• Not applicable

Sensor (The sensor below is determined to be

normal)

• Not applicable

.

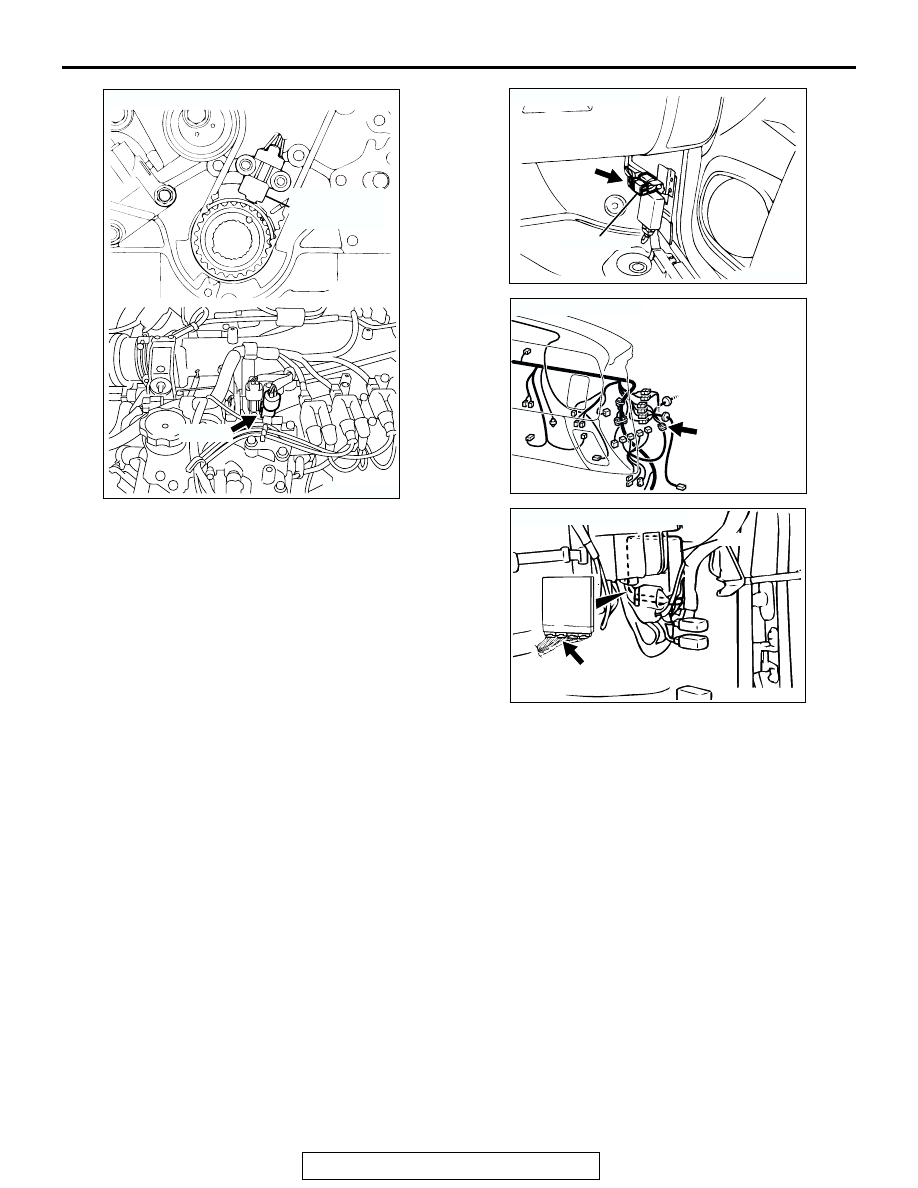

AK200493

CRANKSHAFT

POSITION

SENSOR

A-43(B)

AB

CONNECTOR: A-43

AK201000

MFI RELAY

CONNECTOR: C-59

AB

C-59

AK103911AB

CONNECTOR: C-14

C-14

AK103738AC

CONNECTOR: C-90

PCM

C-90(GR)