Mitsubishi Montero Sport (2004+). Manual - part 160

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-53

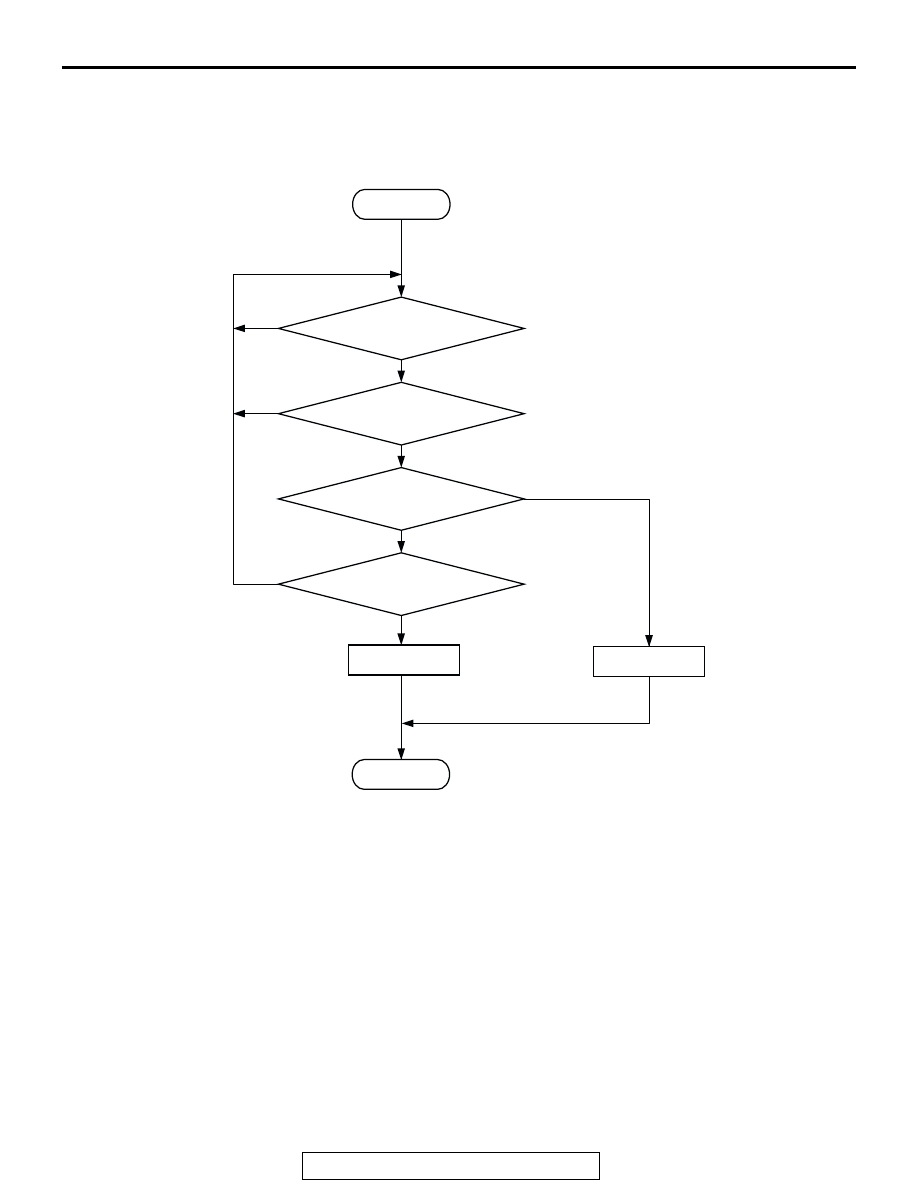

DTC SET CONDITIONS <Range/Performance problem-high input>

Logic Flow Chart

.

Check Conditions

• 8 minutes or more have passed since the starting

sequence was completed, when the engine cool-

ant temperature at engine start is 0

°C (32°F) or

lower.

• Engine speed is lower than 1,500 r/min.

• Throttle position sensor output voltage is lower

than 0.9 volt.

Judgement Criteria

• Manifold Absolute pressure is 89 kPa (26.3

in.Hg) or higher for 2 seconds.

.

START

YES

YES

YES

YES

NO

NO

NO

NO

MONITORING

CONDITIONS

PRESSURE > 89kPa (26.3in.Hg)

CONTINUOUS

FAILURE FOR 2secs

MALFUNCTION

END

GOOD

THROTTLE POSITION < =0.9V

AK301414