Mitsubishi Montero Sport (2004+). Manual - part 139

CYLINDER HEAD AND VALVES

TSB Revision

ENGINE OVERHAUL

11B-31

INSPECTION

M1113007000022

.

CYLINDER HEAD

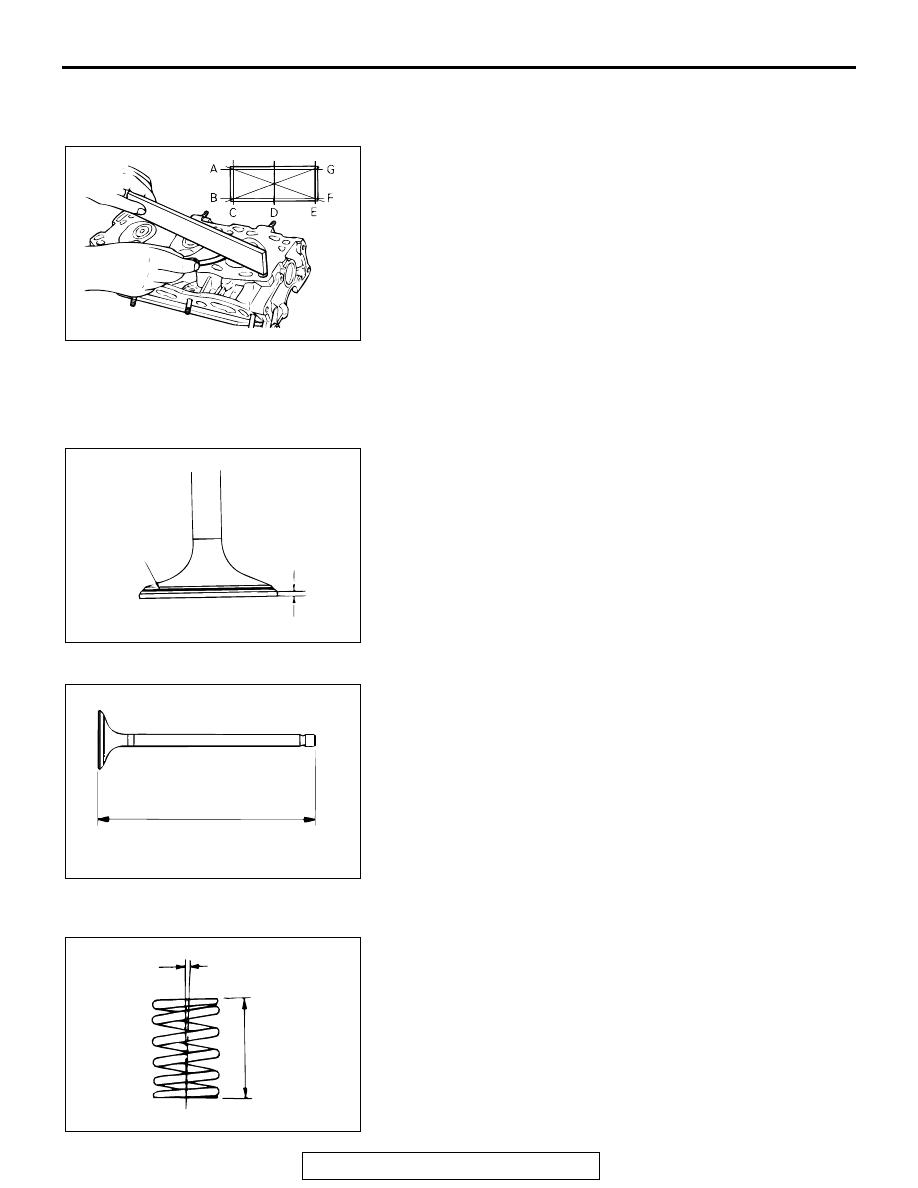

1. Check the cylinder head gasket surface for flatness by using

a straightedge in the directions of A through G shown in the

illustration.

Standard value: 0.03 mm (0.0012 inch)

Limit: 0.2 mm (0.007 inch)

2. If the service limit is exceeded, correct to meet the

specification.

Grinding limit: *0.2 mm (0.007 inch)

3. *If the service limit is exceeded, correct to meet the

specification.

Cylinder head height (specification when new):

120 mm (4.7 inches)

.

VALVE

1. Check the valve face for correct contact. If incorrect, reface

using a valve refacer. The valve should make a uniform

contact with the seat at the center of the valve face.

2. If the margin exceeds the service minimum limit, replace the

valve.

Standard value:

<Intake> 1.0 mm (0.04 inch)

<Exhaust> 1.2 mm (0.05 inch)

Minimum limit:

<Intake> 0.5 mm (0.02 inch)

<Exhaust> 0.7 mm (0.03 inch)

3. Measure the valve's total length. If the measurement is less

than specified, replace the valve.

Standard value:

<Intake> 112.30 mm (4.421 inches)

<Exhaust> 114.11 mm (4.493 inches)

Minimum limit:

<Intake> 111.80 mm (4.402 inches)

<Exhaust> 113.61 mm (4.473 inches)

.

VALVE SPRINGS

1. Measure the free height of the spring and, if it is smaller than

the minimum limit, replace the spring.

Standard value: 51.0 mm (2.01 inches)

Minimum limit: 50.0 mm (1.97 inches)

2. Measure the squareness of the spring and, if the limit is

exceeded, replace the spring.

Standard value: 2

° or less

Limit: 4

°

AKX00733

AKX00619

MARGIN

VALVE SEAT

CONTACT

AB

AKX00624

AKX00607

2˚

FREE

HEIGHT

AB