Mitsubishi Montero Sport (2004+). Manual - part 94

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-17

ASSEMBLY SERVICE POINTS

.

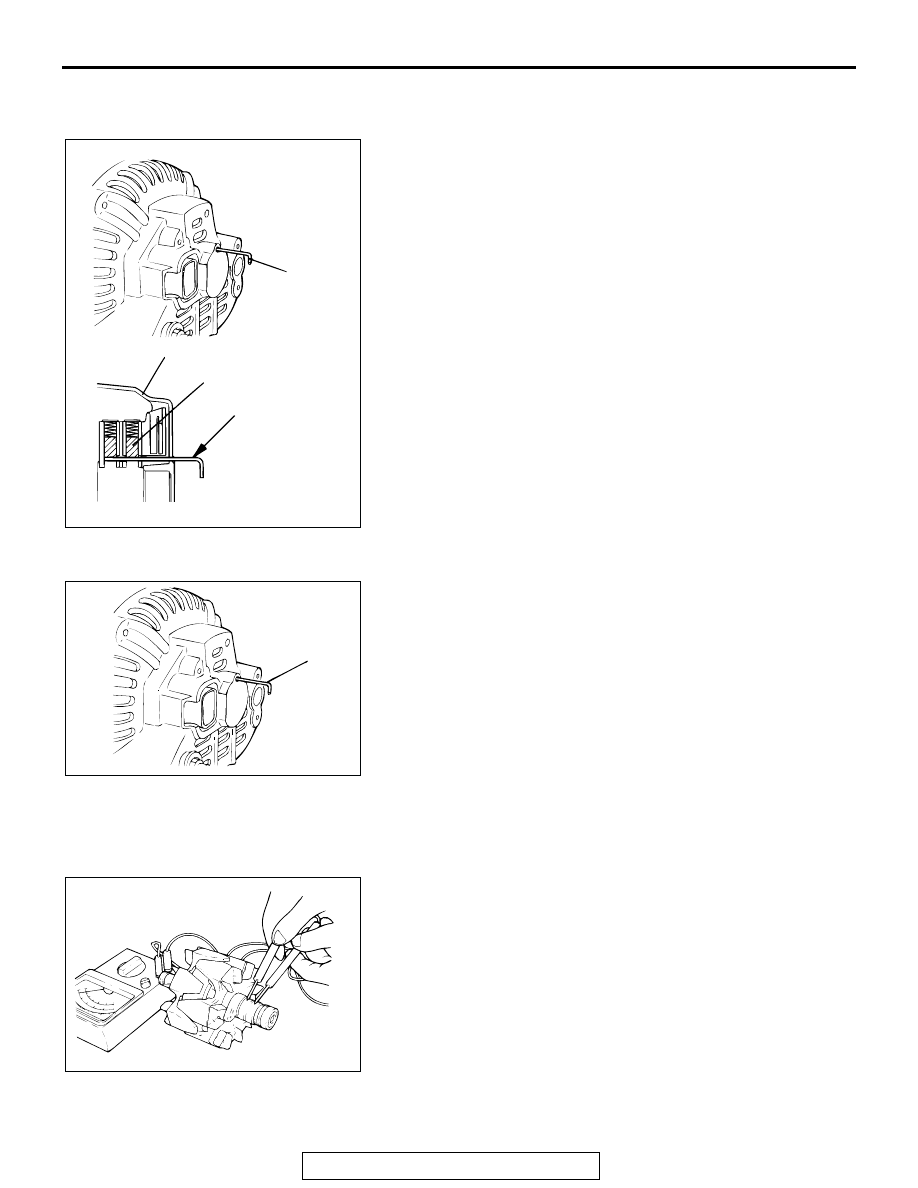

>>A<< REGULATOR ASSEMBLY INSTALLATION

After installing the regulator assembly, insert a wire through the

hole provided on the rear bracket while pressing down on the

brush, and secure the brush.

NOTE: By inserting a wire, the brush will be secured in place,

and the installation of the rotor will be easier.

.

>>B<< ROTOR ASSEMBLY INSTALLATION

After installing the rotor, remove the wire used to secure the

brush.

INSPECTION

M1161001700088

.

ROTOR CHECK

1. Check for continuity between the slip rings of the field coil. If

the resistance value is not within the standard value, replace

the rotor.

Standard value: approximately 2

− 5 Ω

AKX00358

WIRE

REAR BRACKET

BRUSH

WIRE

AB

AKX00359

WIRE

AB

AKX00360