Mitsubishi Montero Sport (2004+). Manual - part 88

SPECIFICATIONS

TSB Revision

ENGINE MECHANICAL

11A-41

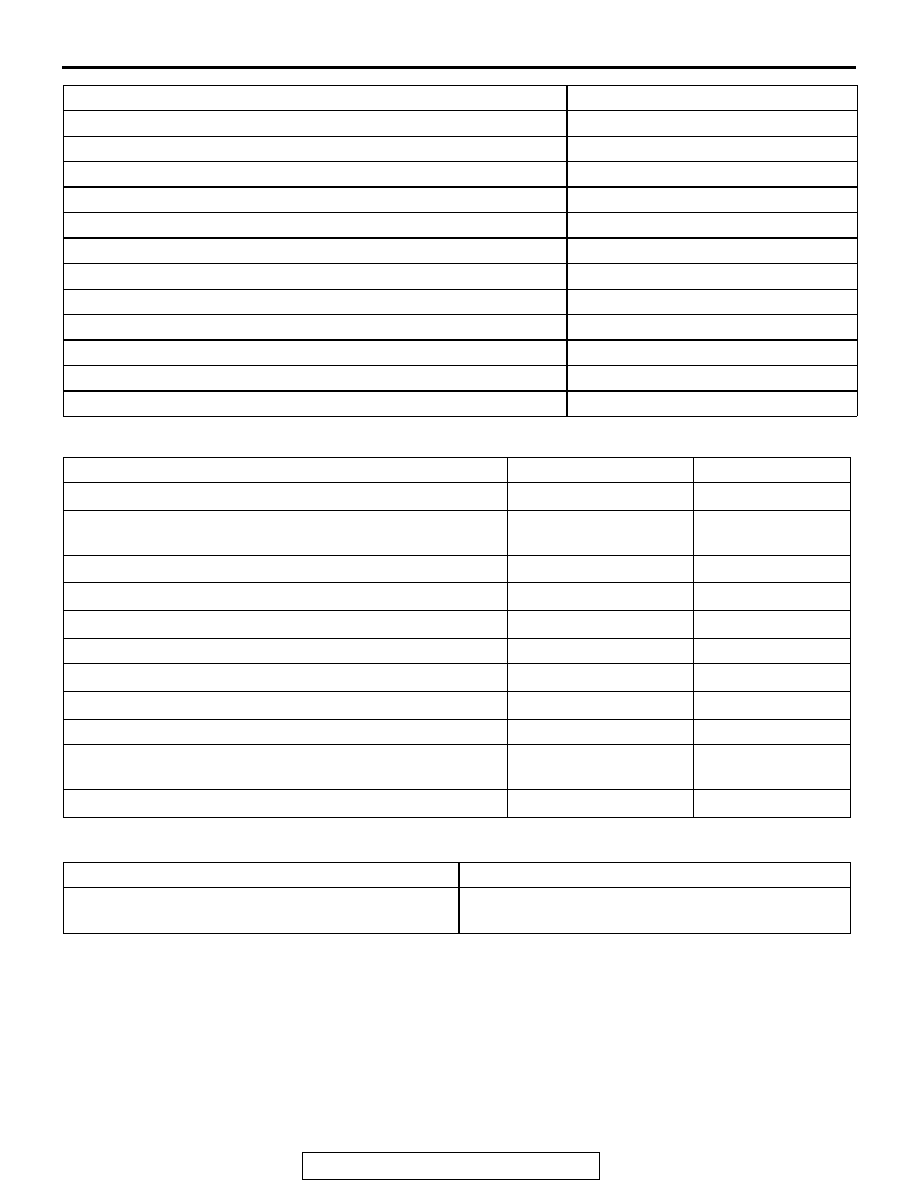

SERVICE SPECIFICATIONS

M1112000300171

SEALANT

M1111000500291

Timing belt lower cover attaching bolt

11 N

⋅m (97 in-lb)

Timing belt lower cover attaching nut

4.9 N

⋅m (43 in-lb)

Timing belt tension arm assembly attaching bolt

44 N

⋅m (33 ft-lb)

Timing belt tension pulley attaching bolt

48 N

⋅m (35 ft-lb)

Timing belt upper cover attaching bolt (6

×18)

11 N

⋅m (97 in-lb)

Timing belt upper cover attaching bolt

14 N

⋅m (124 in-lb)

Timing indicator bracket attaching bolt

11 N

⋅m (97 in-lb)

Transmission mounting bolt

35 N

⋅m (26 ft-lb)

Upper oil pan attaching bolt

5.9 N

⋅m (52 in-lb)

Water outlet pipe attaching bolt

12

− 15 N⋅m (106 − 133 in-lb)

Water passage assembly attaching bolt

17

− 20 N⋅m (12 − 14 ft-lb)

Water pipe and hose assembly attaching bolt

12

− 15 N⋅m (106 − 133 in-lb)

ITEM

SPECIFICATION

ITEM

STANDARD VALUE

LIMIT

Basic ignition timing at idle

5

° BTDC ± 3°

−

Actual ignition timing at curb idle

Approximately 10

°

BTDC

−

CO contents %

0.5 or less

−

HC contents ppm

100 or less

−

Curb idle speed r/min

700

± 100

−

Compression pressure (250

− 400 r/min) kPa (psi)

1200 (171)

Minimum 890 (127)

Compression pressure difference of all cylinder kPa (psi)

−

98 (14)

Intake manifold vacuum at curb idle kPa (in Hg)

−

Minimum 60 (18)

Timing belt tensioner torque N

⋅m (in-lb)

4.4 (39)

Timing belt tensioner adjuster rod protrusion amount mm

(in)

3.8

− 5.0 (0.15 − 0.20)

−

Timing belt tensioner adjuster rod movement mm (in)

Within 1 (0.04)

−

ITEM

SPECIFIED SEALANT

Oil pan

MITSUBISHI GENUINE Part No. MD970389 or

equivalent