Mitsubishi Montero Sport (2004+). Manual - part 69

TIGHTENING TORQUE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-35

TIGHTENING TORQUE

M1001001100265

Each torque value in the table is a standard value for

tightening under the following conditions.

1. Bolts, nuts and washers are all made of steel and

plated with zinc.

2. The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:

1. If toothed washers are inserted.

2. If plastic parts are fastened.

3. If bolts are tightened to plastic or die-cast

inserted nuts.

4. If self-tapping screws or self-locking nuts are

used

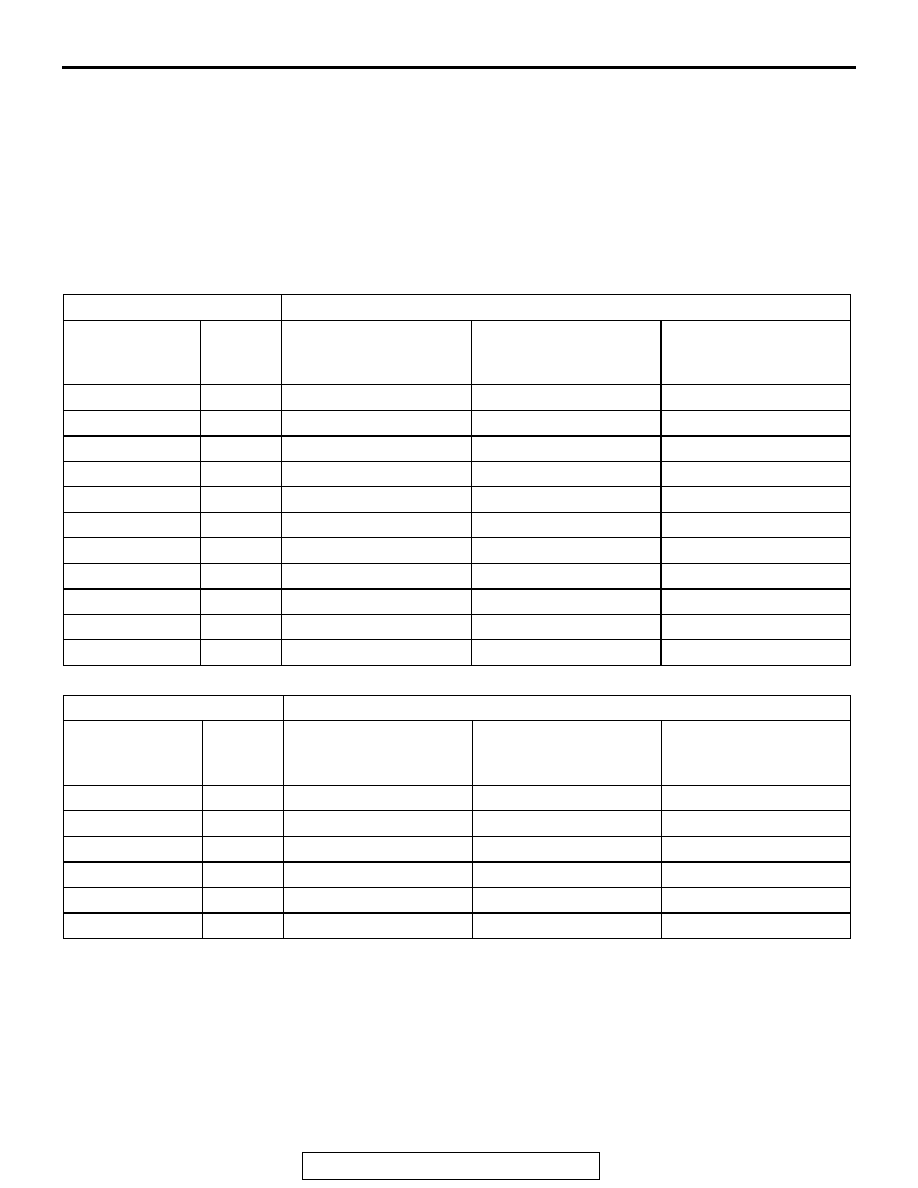

Standard bolt and nut tightening torque

Flange bolt and nut tightening torque

THREAD SIZE

STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER

(mm)

PITCH

(mm)

HEAD MARK "4"

HEAD MARK "7"

HEAD MARK "8"

M5

0.8

2.5 N

⋅m (22 in-lb)

4.9 N

⋅m (43 in-lb)

5.9 N

⋅m (52 in-lb)

M6

1.0

4.9 N

⋅m (43 in-lb)

8.8 N

⋅m (78 in-lb)

9.8 N

⋅m (87 in-lb)

M8

1.25

12 N

⋅m (106 in-lb)

22 N

⋅m (16 ft-lb)

25 N

⋅m (18 ft-lb)

M10

1.25

24 N

⋅m (18 ft-lb)

44 N

⋅m (33 ft-lb)

52 N

⋅m (38 ft-lb)

M12

1.25

41 N

⋅m (30 ft-lb)

81 N

⋅m (60 ft-lb)

96 N

⋅m (71 ft-lb)

M14

1.5

72 N

⋅m (53 ft-lb)

137 N

⋅m (101 ft-lb)

157 N

⋅m (116 ft-lb)

M16

1.5

111 N

⋅m (82 ft-lb)

206 N

⋅m (152 ft-lb)

235 N

⋅m (173 ft-lb)

M18

1.5

167 N

⋅m (123 ft-lb)

304 N

⋅m (224 ft-lb)

343 N

⋅m (253 ft-lb)

M20

1.5

226 N

⋅m (167 ft-lb)

412 N

⋅m (304 ft-lb)

481 N

⋅m (355 ft-lb)

M22

1.5

304 N

⋅m (224 ft-lb)

559 N

⋅m (412 ft-lb)

647 N

⋅m (477 ft-lb)

M24

1.5

392 N

⋅m (289 ft-lb)

735 N

⋅m (542 ft-lb)

853 N

⋅m (629 ft-lb)

THREAD SIZE

STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER

(mm)

PITCH

(mm)

HEAD MARK "4"

HEAD MARK "7"

HEAD MARK "8"

M6

1.0

4.9 N

⋅m (43 in-lb)

9.8 N

⋅m (87 in-lb)

12 N

⋅m (106 in-lb)

M8

1.25

13 N

⋅m (115 in-lb)

24 N

⋅m (18 ft-lb)

28 N

⋅m (21 ft-lb)

M10

1.25

26 N

⋅m (19 ft-lb)

49 N

⋅m (36 ft-lb)

57 N

⋅m (42 ft-lb)

M10

1.5

24 N

⋅m (18 ft-lb)

44 N

⋅m (33 ft-lb)

54 N

⋅m (40 ft-lb)

M12

1.25

46 N

⋅m (34 ft-lb)

93 N

⋅m (69 ft-lb)

103 N

⋅m (76 ft-lb)

M12

1.75

42 N

⋅m (31 ft-lb)

81 N

⋅m (60 ft-lb)

96 N

⋅m (71 ft-lb)