Mitsubishi Montero (2004+). Manual - part 245

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-467

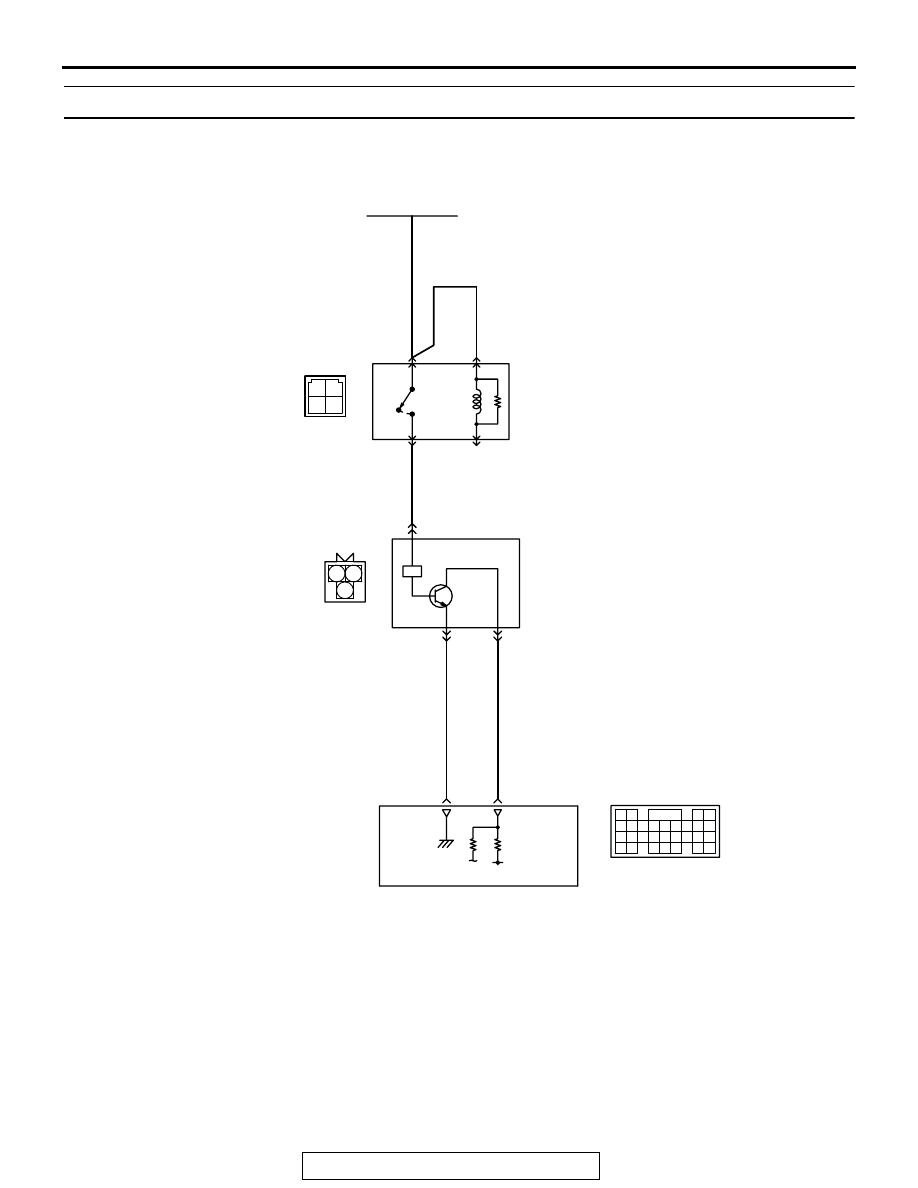

DTC P0335: Crankshaft Position Sensor Circuit

WHITE-

BLA

C

K

WHITE-

BLA

C

K

RED

AK201142

SKY B

U

LE

BLUE-RED

MFI RELAY

BATTERY

70

88

3

2

1

3 4

1 2

B-22X

5V

POWERTRAIN

CONTROL

MODULE (PCM)

3

1 2

B-36

MU802603

3

2

1

4

CRANKSHAFT

POSITION

SENSOR

Crankshaft Position Sensor Circuit

61

656667686970 717273

74757677787980 8182

8384

858687

8889

62

6364

D-134

(MU803804)