Mitsubishi Montero (2004+). Manual - part 131

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-11

CAUTION

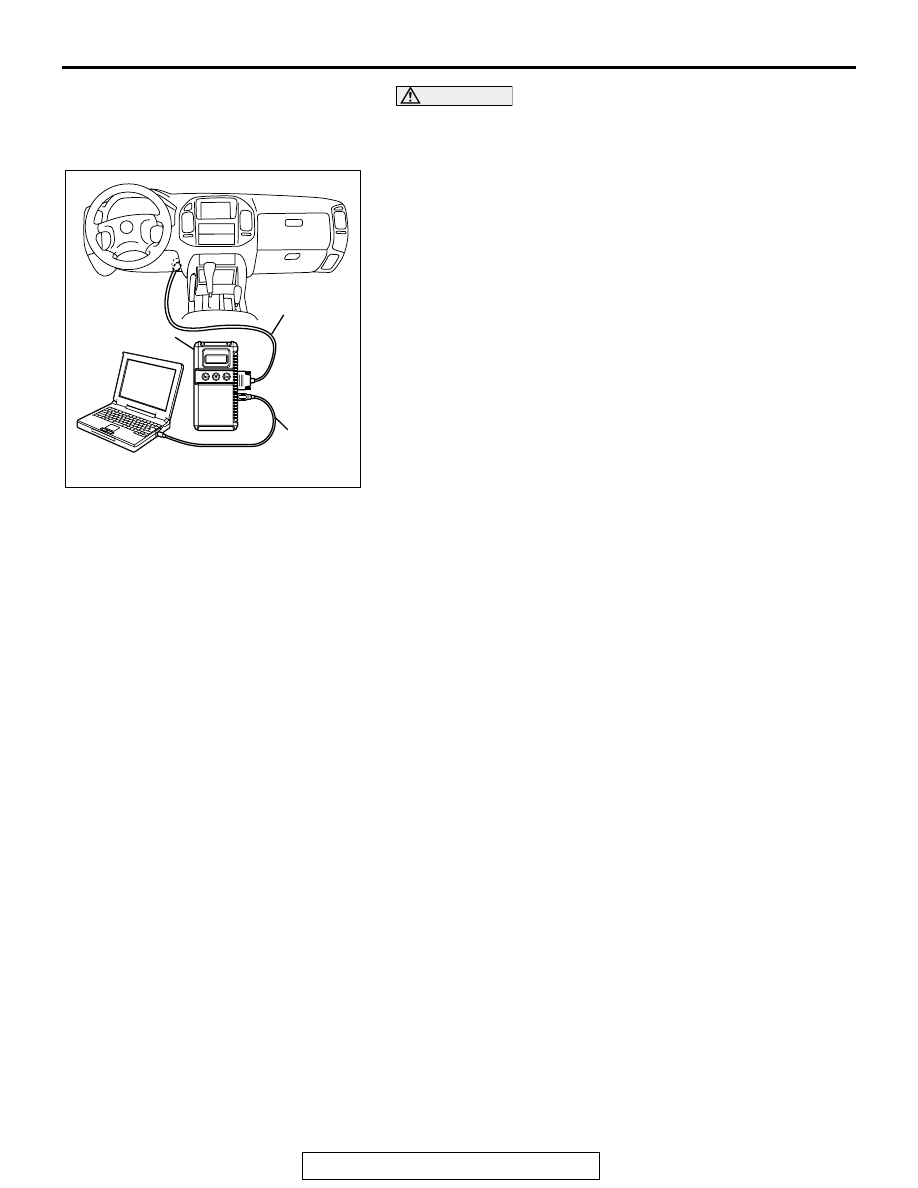

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "MFI" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Actuator Test."

8. Choose an appropriate item and select the "OK" button.

PROVISIONAL DTCs [MUT-III OBD-II Test Mode -

Results (Mode 7)]

The scan tool MB991958 (MUT-III Sub Assembly) will display

the Provisional DTCs reported by PCM if the PCM detects

some malfunction for "Misfire", "Fuel System" and "Compre-

hensive" monitoring during a SINGLE Driving Cycle. The

intended use of this data is to assist the technician after a vehi-

cle repair, and after clearing diagnostic information, by report-

ing test result after a SINGLE Driving Cycle. Note that the test

results reported by this mode do not necessarily indicate a

faulty component/system. If test results indicate a failure after

ADDITIONAL (consecutive) driving, then the Malfunction Indi-

cator Lamp (SERVICE ENGINE SOON) will be illuminated and

a DTC will set.

AK302970

AB

MB991911

MB991824

MB991827