Content .. 1032 1033 1034 1035 ..

Mitsubishi Montero (2004+). Manual - part 1034

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-135

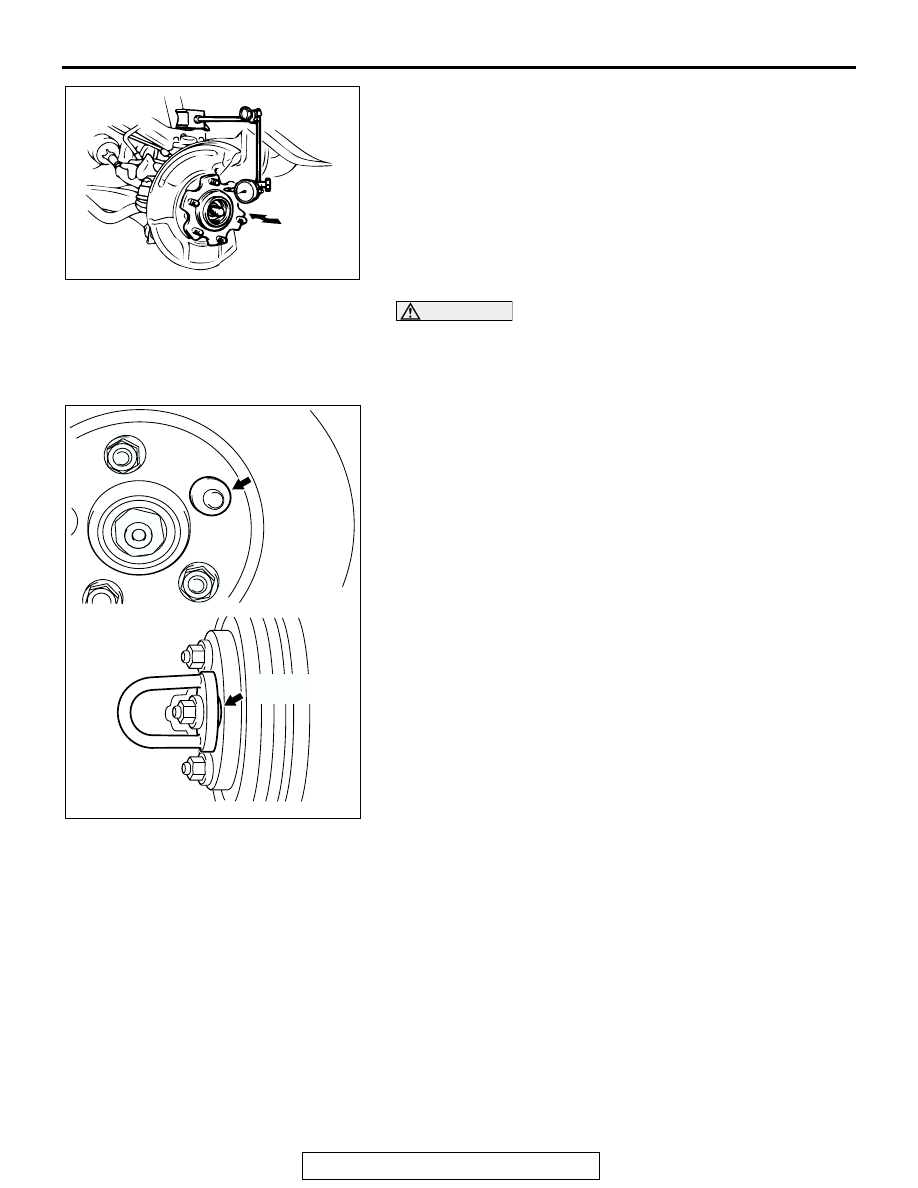

(2) Remove the brake disc. Then place a dial gauge as

shown in the illustration, and then move the hub in the

axial direction and measure the play.

Limit: 0 mm (0 inch)

(3) If the play exceeds the limit, disassemble the hub and

knuckle assembly to check each part.

(4) If the play does not exceed the limit, install the brake disc

at a different phase, and then check the run-out of the

brake disc again.

CAUTION

• After a new brake disc is installed, always grind the

brake disc with a on-car type brake lathe. If this step is

not carried out, the brake disc run-out will exceed the

specified value, resulting in judder.

• When the on-car type lathe is used, first install a M12

flat washer on the stud bolt in the brake disc side

according to the figure, and then install the adapter. If

the adapter is installed without a M12 flat washer, the

brake disc rotor may be deformed, resulting in inaccu-

rate grinding.

• Grind the brake disc with all wheel nuts diagonally and

equally tightened to the specified torque 100 N

⋅m (74

ft-lb). When all numbers of wheel nuts are not used, or

the tightening torque is excessive or not equal, the

brake disc rotor or drum may be deformed, resulting in

judder.

6. If the run-out cannot be corrected by changing the phase of

the brake disc, replace the brake disc or turn rotor with an

on-car type brake lathe ("Accuturn-8750" or equivalent).

ACX00670

AC005154 AB

M12 PLANE

WASHER

M12 PLANE

WASHER