Mitsubishi Montero (2002-2004). Manual - part 886

DIAGNOSTIC TROUBLE CODE PROCEDURES <AUTOMATIC TRANSMISSION>

TSB Revision

DIAGNOSTIC TROUBLE CODE PROCEDURES

23Ac-27

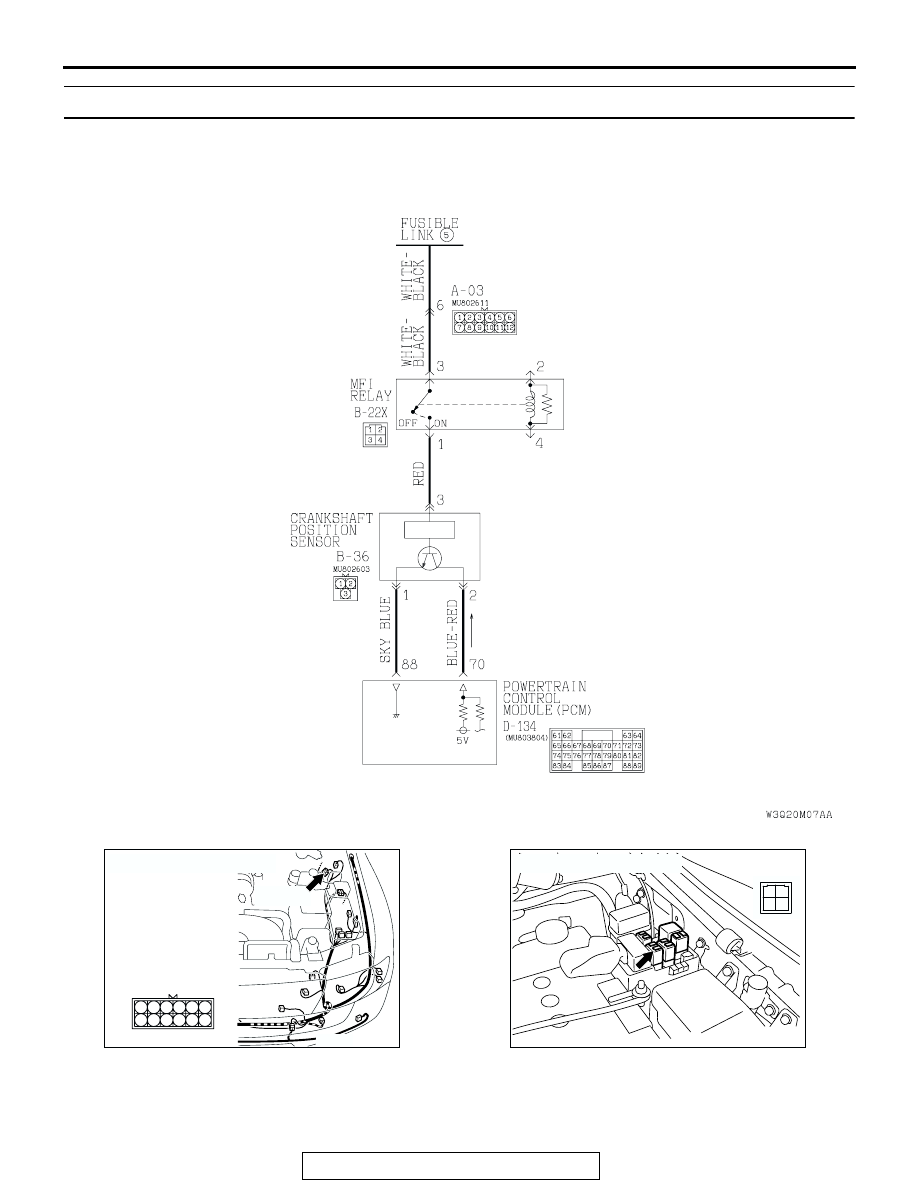

DTC 21: Crankshaft Position Sensor System

AC205188AB

Crankshaft Position Sensor System Circuit

AC204167

CONNECTOR : A-03

AT

A-03 (B)

6

12

5

3 4

2

1

9 10

8

7

11

AC204745

CONNECTOR : B-22X

AB

1

3 4

2