Mitsubishi Montero (2002-2004). Manual - part 833

TIMING BELT

TSB Revision

ENGINE MECHANICAL

11A-37

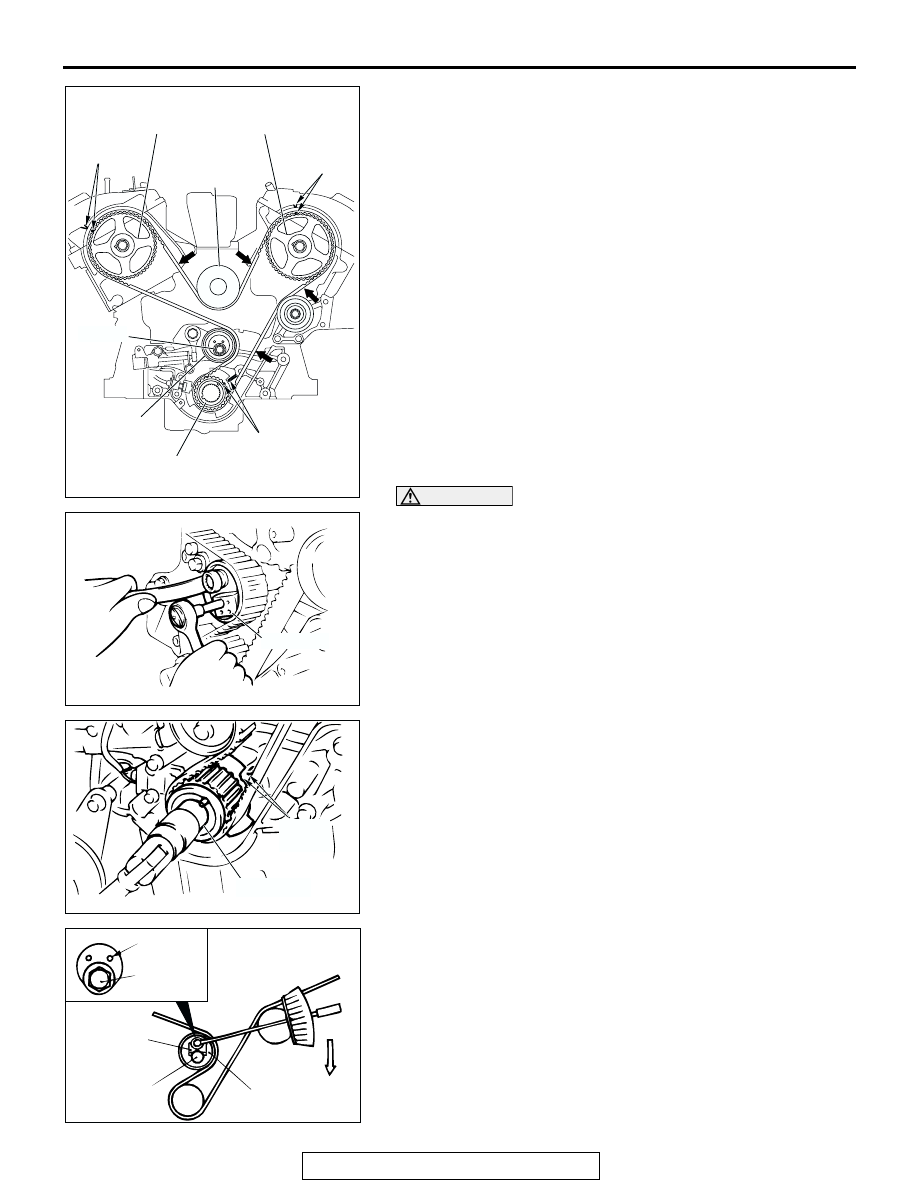

3. Turn the camshaft sprocket counterclockwise until the

tension side of the timing belt is firmly stretched. Check all

timing marks again.

CAUTION

When tightening the center bolt, be careful that the ten-

sioner pulley does not turn with the bolt.

4. Use special tool MD998767 to push the tensioner pulley into

the timing belt, and then temporarily tighten the center bolt.

5. Use special tool MD998769 to turn the crankshaft 1/4 turn

counterclockwise and then turn it again clockwise until the

timing marks are aligned.

6. Loosen the center bolt of the tensioner pulley. Use special

tool MD998767 and a torque wrench to apply the standard

torque to the timing belt as shown in the illustration. Then

tighten the center bolt to the specified torque.

• Standard value: 4.4 N⋅m (39 in-lb) <Timing belt ten-

sion torque>

• Tightening torque: 48 ± 6 N⋅m (36 ± 4 ft-lb)

ACX00537

TIMING

MARK

TIMING

MARK

TIMING

MARK

CAMSHAFT

SPROCKET

(RIGHT BANK)

CAMSHAFT

SPROCKET

(LEFT BANK)

CRANKSHAFT

SPROCKET

TENSION

PULLEY

AC

CENTER

BOLT

WATER

PUMP

PULLEY

ACX00335AB

MD998767

ACX00336AB

MD998769

TIMING

MARK

ACX00756AB

CENTER

BOLT

PIN HOLES

48 ± 6 N·m

36 ± 4 ft-lb

MD998767

TENSION

PULLEY

4.4 N·m

(39 in-lb)