Mitsubishi Montero (2002-2004). Manual - part 745

TSB Revision

SYMPTOM PROCEDURES

13Ad-29

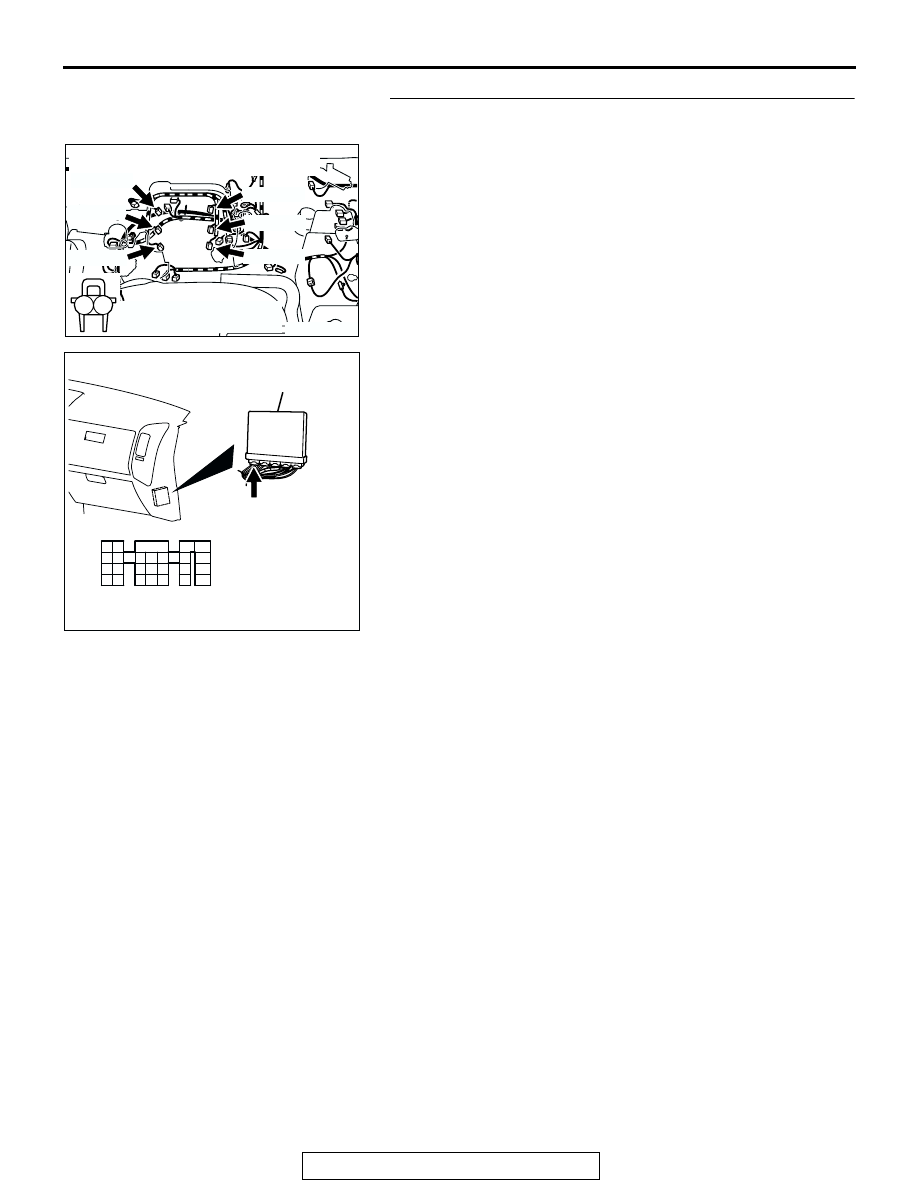

STEP 14. Check for harness damage between injector

connector and PCM connector.

a. Check the harness wire between injector connector B-

01 (terminal No. 2) and PCM connector D-132 (terminal

No. 1) when checking No. 1 cylinder injector.

b. Check the harness wire between injector connector B-

33 (terminal No. 2) and PCM connector D-132 (terminal

No. 5) when checking No. 2 cylinder injector.

c. Check the harness wire between injector connector B-

02 (terminal No. 2) and PCM connector D-132 (terminal

No. 14) when checking No. 3 cylinder injector.

d. Check the harness wire between injector connector B-

35 (terminal No. 2) and PCM connector D-132 (terminal

No. 21) when checking No. 4 cylinder injector.

e. Check the harness wire between injector connector B-

03 (terminal No. 2) and PCM connector D-132 (terminal

No. 2) when checking No. 5 cylinder injector.

f. Check the harness wire between injector connector B-

11 (terminal No. 2) and PCM connector D-132 (terminal

No. 6) when checking No. 6 cylinder injector.

Q: Is the harness wire in good condition?

YES : Check the following items, and repair or replace the

defective items.

a. Check the ignition coil, spark plugs, spark plug

cables.

b. Check if the injectors are clogged.

c. Check compression pressure.

d. Check fuel lines for clogging.

e. Check if the foreign materials (water,

kerosene, etc.) got into fuel.

f. Check the EGR valve.

Then confirm that the malfunction symptom is

eliminated.

NO : Repair it. Then confirm that the malfunction symptom

is eliminated.

AK200960

1

2

B-03(GR)

B-11(GR)

B-35(GR)

B-33(GR)

B-02(GR)

B-01(GR)

CONNECTORS: B-01, B-02, B-03, B-11,

B-33, B-35

AB

HARNESS CONNECTOR:

COMPONENT SIDE

AK200938

2

3

4

5

6

7

8

9

1

10

14

15

16

17

18

19

20

21

22

23

24

25

26

27

11

12

13

AB

CONNECTOR: D-132

HARNESS CONNECTOR:

COMPONENT SIDE

PCM

D-132(GR)