Mitsubishi Montero (2002-2004). Manual - part 674

TSB Revision

DIAGNOSTIC TROUBLE CODE PROCEDURES

13Ac-393

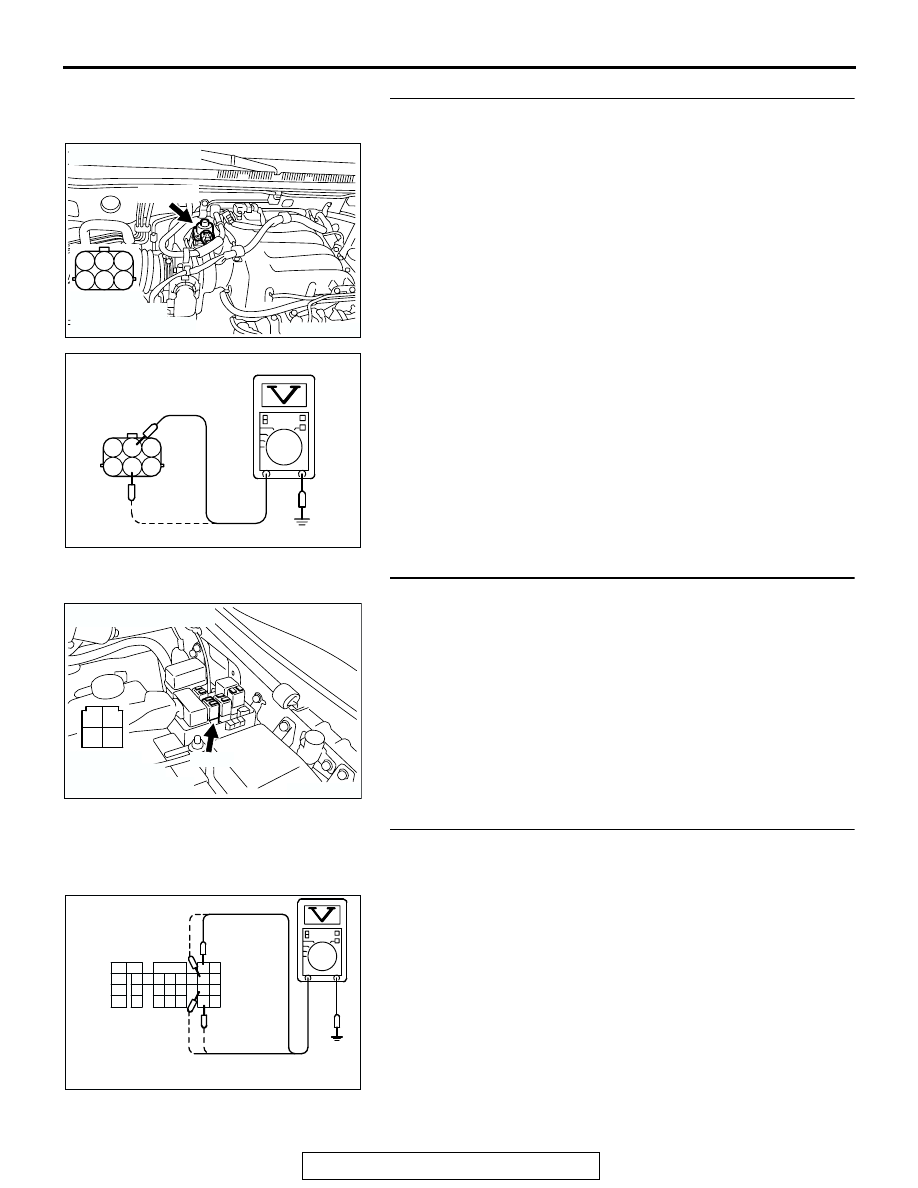

STEP 3. Measure the power supply voltage at EGR valve

motor harness side connector B-56.

(1) Disconnect the connector B-56 and measure at the harness

side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 2, No. 5 and

ground.

• Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is battery positive voltage (approximately 12 volts)

present?

YES : Go to Step 5.

NO : Go to Step 4.

STEP 4. Check connector B-22X at MFI relay for damage.

Q: Is the connector in good condition?

YES : Repair harness wire between MFI relay connector B-

22X (terminal No. 1) and idle air control motor

connector B-56 (terminal No. 2, No. 5) because of

open circuit or short circuit to ground. Then go to Step

12.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 12.

STEP 5. Measure the power supply voltage at PCM

connector D-132 by backprobing.

(1) Do not disconnect the connector D-132.

(2) Measure the voltage between terminal (No. 3, No. 12, No.

19, No. 26) and ground by backprobing.

• The voltage is 1volt or lower for approximately 3 sec-

onds, then changes to the battery positive voltage when

the Ignition switch is turned from the "LOCK" (OFF)

position to the "ON" position.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the voltage normal?

YES : Go to Step 8.

NO : Go to Step 6.

AK200967

1

2

3

4

5

6

AB

HARNESS

CONNECTOR:

COMPONENT SIDE

B-56(GR)

CONNECTOR: B-56

1

2

3

4

5

6

AK201419

B-56 HARNESS

CONNECTOR:

CONPONENT SIDE

AB

AK200951

2 1

3

4

B-22X

AB

CONNECTOR: B-22X

HARNESS

CONNECTOR:

COMPONENT SIDE

1

2

3

5

6 7 8 9

4

20

21 22

232425

2627

10111213

14 15

16 1718

19

AK201420

D-132 HARNESS

CONNECTOR:

HARNESS SIDE

AB